Equipment for producing cyclohexenol through benzene plus hydrogen

A technology for hydrogenation of cyclohexene and benzene, applied in the field of chemical equipment, can solve the problem of not providing a production device, etc., and achieve the effects of good safety, automation, and rich monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

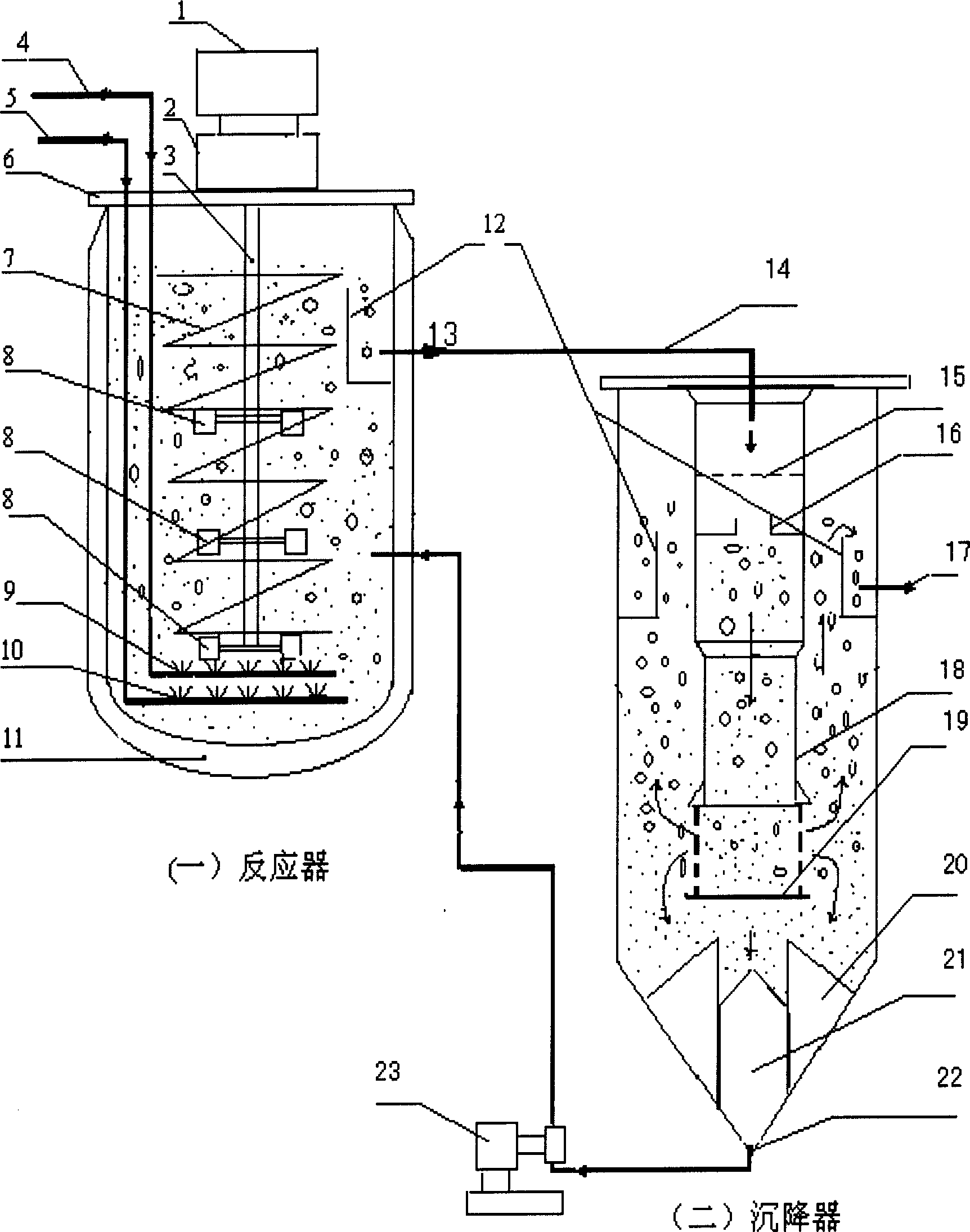

[0012] Figure 1 is a schematic diagram of a device for producing cyclohexene by hydrogenation of benzene.

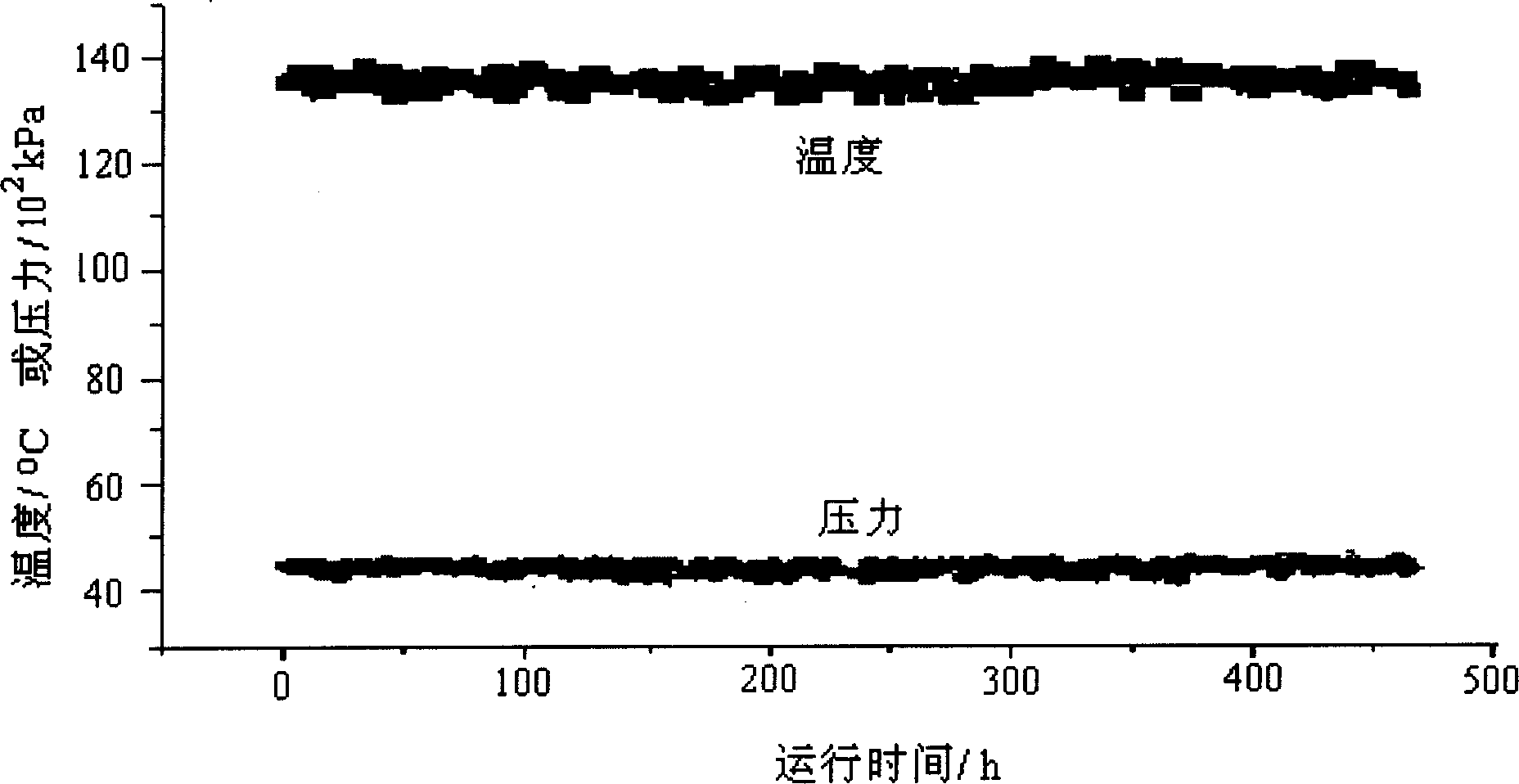

[0013] Figure 2 is the curve of temperature and pressure changing with time within 466h.

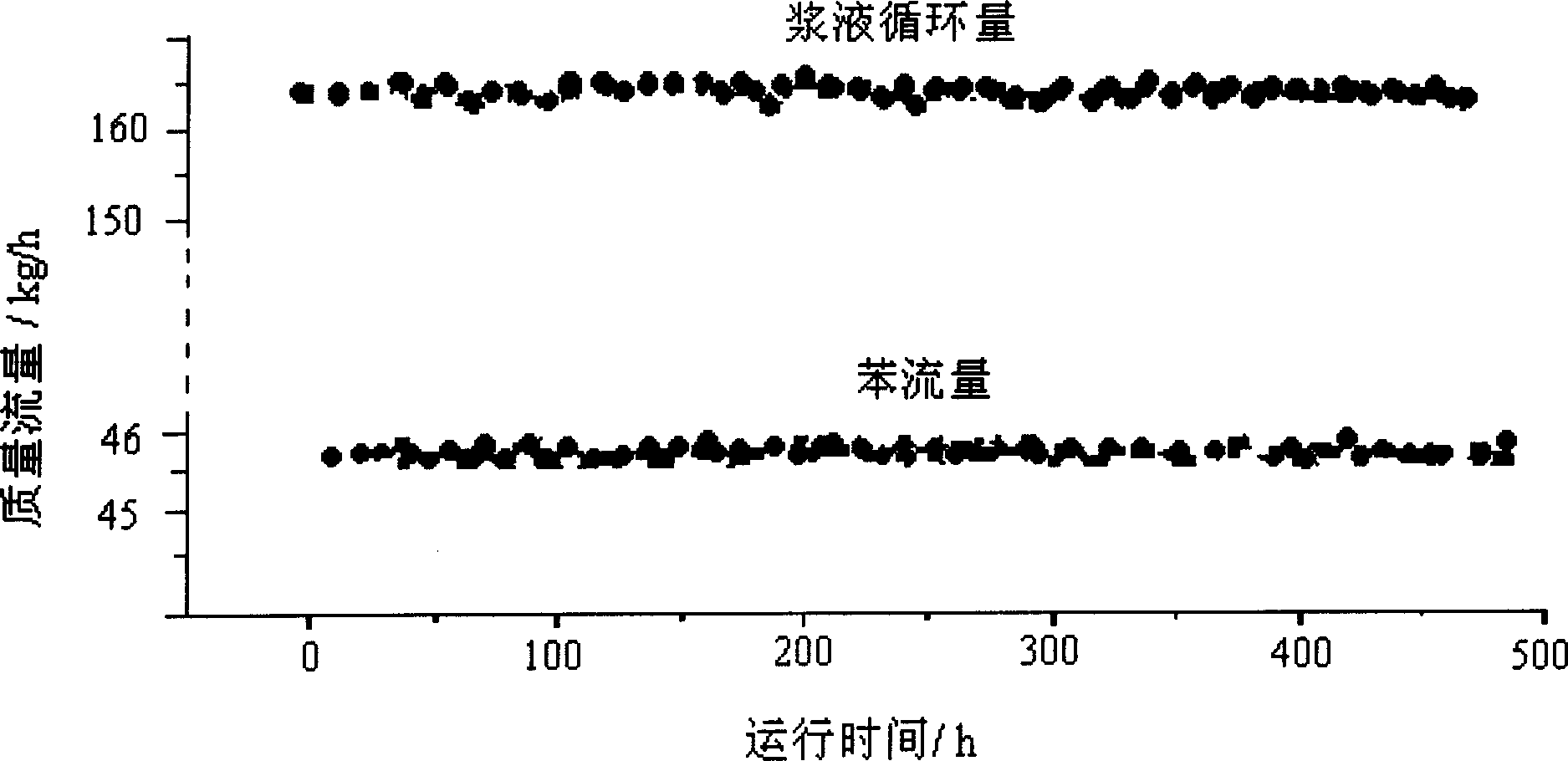

[0014] Figure 3 is a curve of the benzene flow rate and slurry circulation volume versus time within 466 hours.

[0015] Figure 4 is the curve of the liquid level changing with time within 466h.

[0016] Figure 5 shows the conversion of benzene and the selectivity of cyclohexene at 50-90 hours.

[0017] Figure 1, in the reactor, 1 is the motor, 2 is the magnetic seal stirring device, 3 is the stirring shaft, 4 is the hydrogen inlet pipeline, 5 is the benzene inlet pipeline, 6 is the sealing cover, 7 is the heat exchange coil, 8 is Multi-stage stirring blades, 9 is a gas phase distributor, 10 is a liquid phase distributor, 11 is a heat exchange jacket, 12 is an overflow weir, 13 is a product outlet,

[0018] In the settler, 14 is a diversion pipe, 15 is a baffle with a grid, 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com