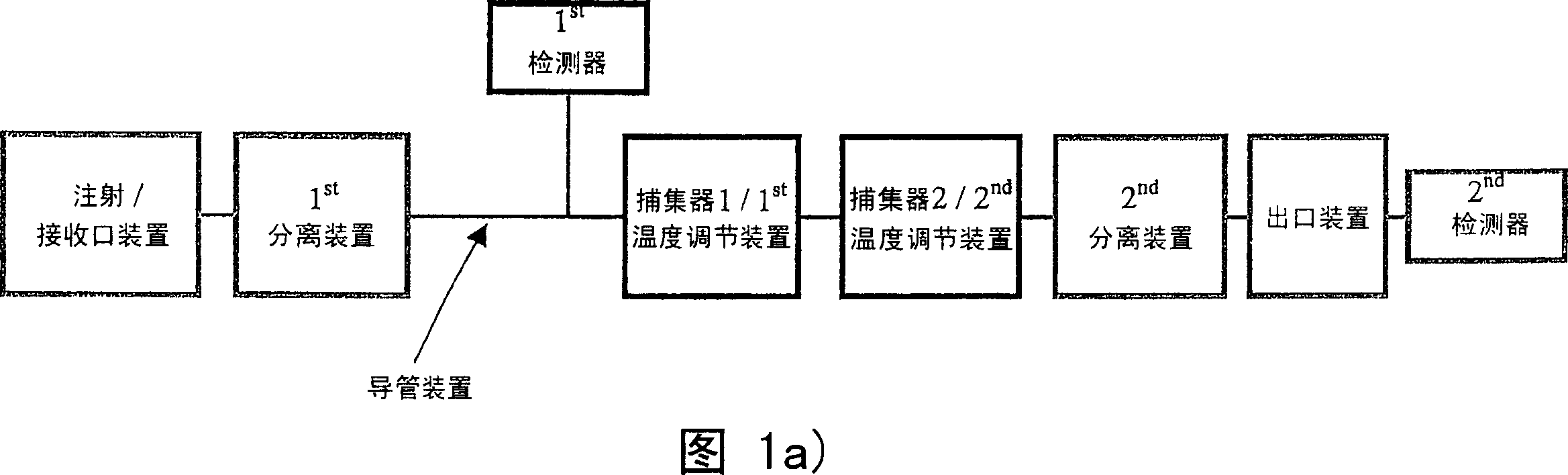

Novel multiple-dimension gas phase chromatographic device and analyte conveying method using multiple cooling wire connections

A technology of cooling part and connecting section, applied in the field of gas chromatography, to achieve the effect of optimizing separation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

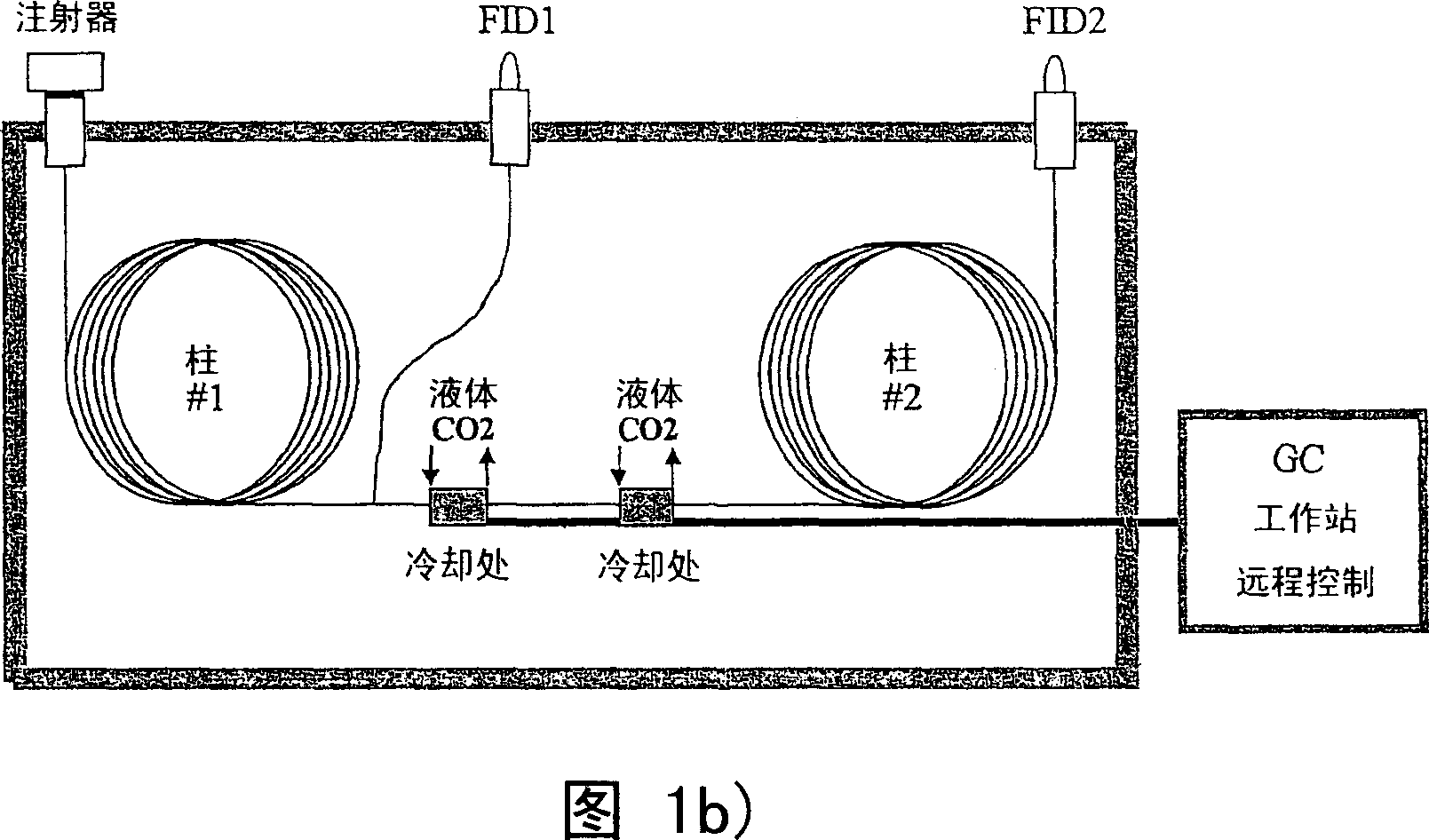

[0128] general conditions

[0129] 1. Raw materials used

[0130] Hyacinth oil was purchased from Quest International (Naarden, Netherlands), jasmine oil was purchased from Danisco (Zug, Switzerland), and lavender oil was purchased from Firmenich SA (Geneva, Switzerland). Bergamot oil was a commercially available test sample. All pure compounds were of analytical grade (>97% purity), except α-isomethylionone (>95%). α-ionone, β-ionone, (+ / -)-linalool and (-)-linalool were purchased from Fluka (Buchs, Switzerland), and α-isomethylionone was purchased from Bedoukian (Danbury, USA). ), Tetrahydroxylinalool was purchased from BASF AG (Frankfurt, Germany), Zestover (2,4-Dimethyl-3-cyclohexene-1-carbaldehyde) was purchased from Givaudan (Vernier, Switzerland). Nonanal, terpinolene and phenylethyl alcohol were purchased from Firmenich SA. Compounds and mixtures were diluted 1:20 (v / v) with ethyl acetate (analytical grade, SDS, Peypin, France) before injection.

[0131] 2. Gas...

Embodiment 9

[0144] For the olfactometric characterization of the enantiomers, the outlet of the cryo-trap was directly connected via a fused silica "Y" connector to the FID and the same suction port as described above. The testers are spice producers. Record the onset and end times of the olfactory measurement peaks and the odor description. This experiment was repeated 3 times.

[0145] 6. Data processing

[0146] Peak heights, full width at half maximum and resolving power were calculated by Galaxie Chromatography Data System software (Varian-JMBS). The resolution between two consecutive peaks is calculated according to the following formula:

[0147] Rs = 1.18 × R t 2 - R t 1 ω 2 + ω ...

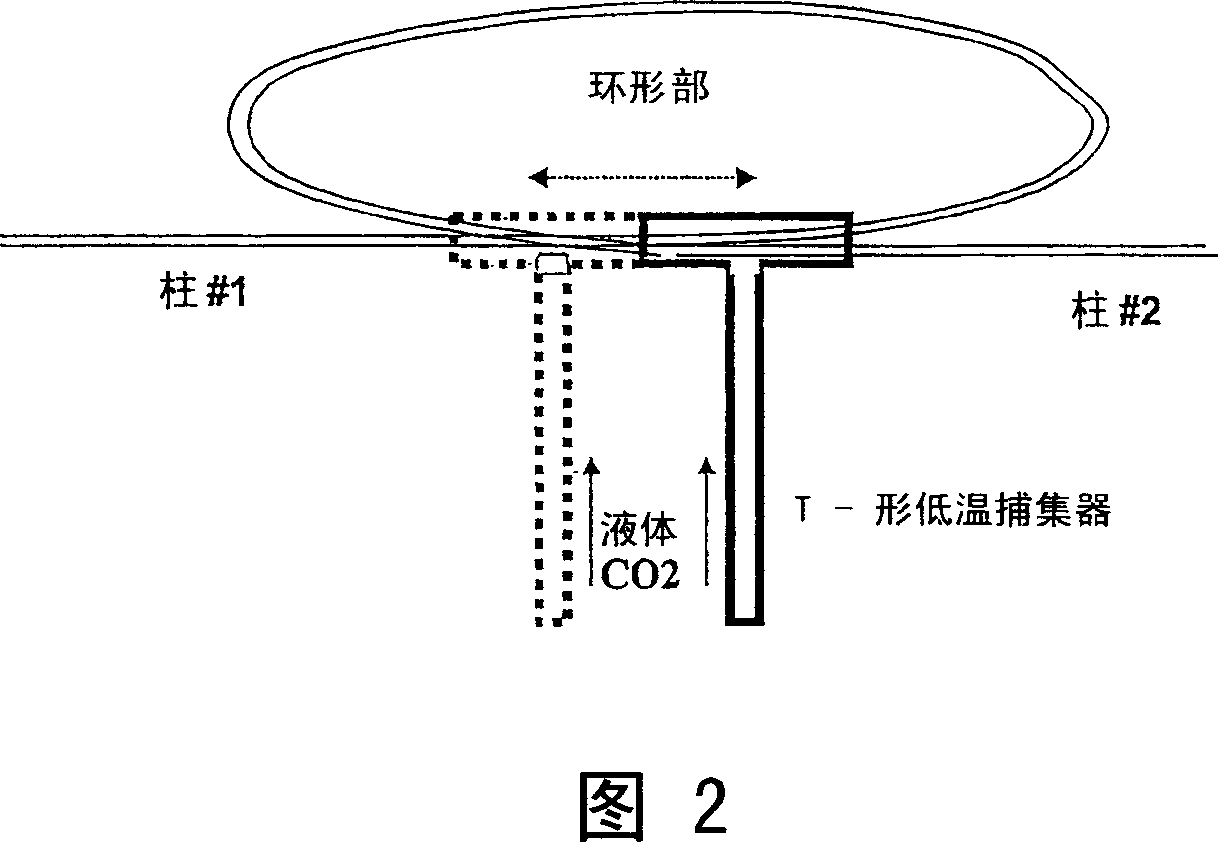

Embodiment 1

[0150] Manually Operated Connections

[0151] Very simple cryogenic control can be achieved by passing two annular columns through a T-shaped stainless steel tube as shown in Figure 2. Liquid CO 2 Inducted into the third branch of the T. Movement of the T along the double line of the column can be accomplished manually from outside the box with a rod attached to the T. Connect the two columns together using a dead-volume-free cross-tip. The cross head is connected to a flame ionization detector and a pressure controller by a deactivation capillary.

[0152] It is known that the linalool enantiomers can be separated well using a 2,6-di-O-methyl-3-O-phenyl-β-cyclodextrin column. As a preliminary test, the racemate was injected into the MDGC in the structure of Figure 4 without cryogenic trapping. The enantiomers were not separated (Figure 6B). According to the steps in Figure 4, during the second experiment, the linalool peak (Figure 6A) flowing out from the first column...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com