Beta-hydroxyalkylamide curing agent preparation method

A technology of hydroxyalkylamide and curing agent, which is applied in the field of preparation of β-hydroxyalkylamide curing agent, can solve the problems of increased solvent consumption and post-processing steps, large equipment investment, and low total yield, and achieve strong industry Effects of utilization and popularization, simple operation unit, and low investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

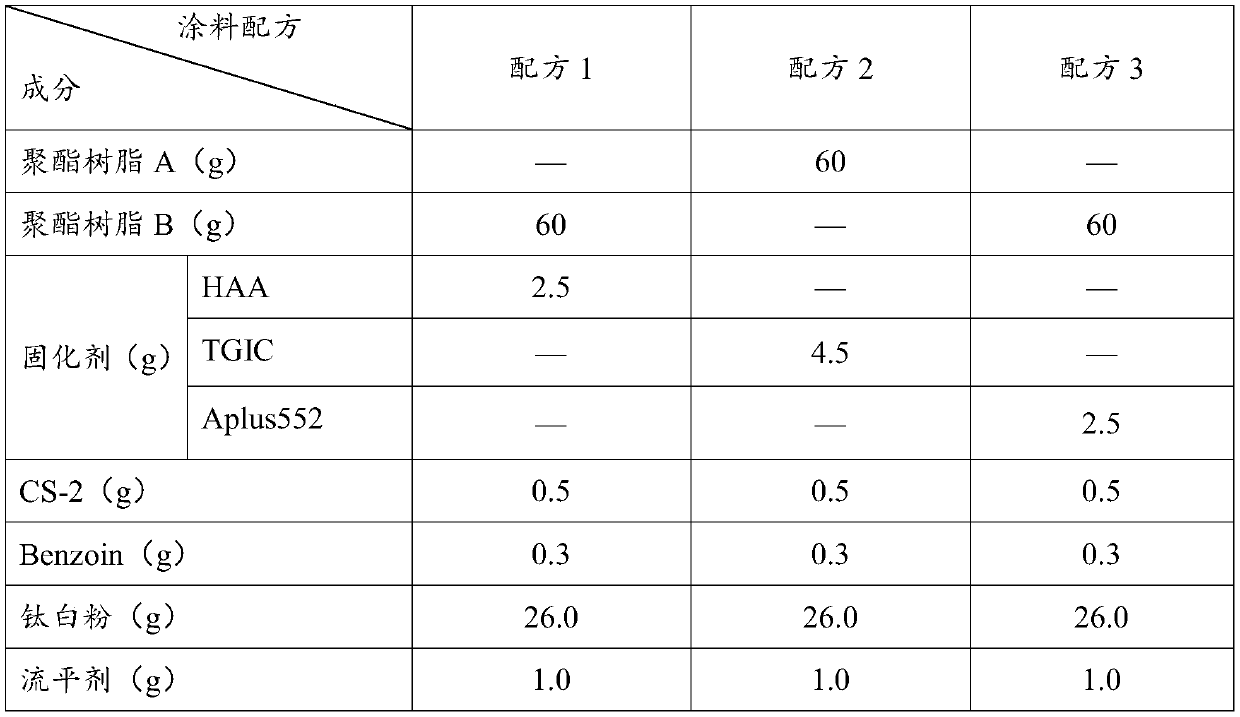

Examples

Embodiment 1

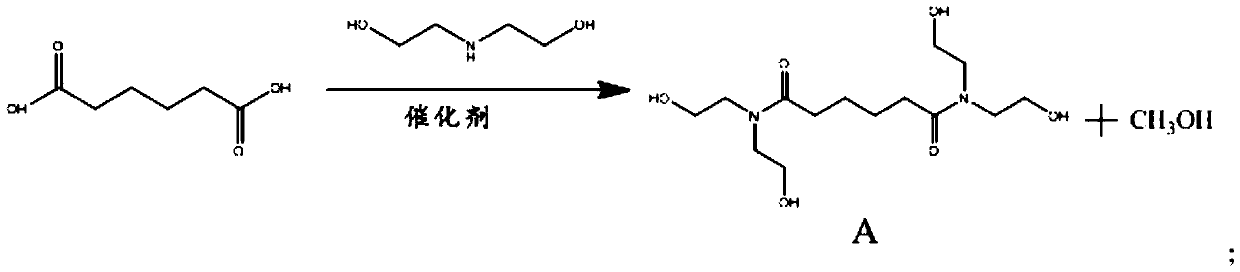

[0028] A preparation method of β-hydroxyalkylamide curing agent, comprising the following preparation steps:

[0029] (1) Get four-necked bottle, device mechanical stirring, condenser tube and thermometer, take by weighing dimethyl adipate, diethanolamine and catalyst (diethanolamine and dimethyl adipate mol ratio are 2.5, catalyst and product A weight ratio is 0.14%), added to the reaction flask, heated up to 65°C for reaction under reduced pressure, stirred for 2 hours, evaporated methanol as a volatile component, and obtained tetrahydroxyethyl adipamide solution, which was product A;

[0030] (2) The product A was solidified in a tray for 10 hours, crushed into powder and dried at 85°C. Crushed and dried to obtain white powder solid tetrahydroxyethyl adipamide curing agent.

Embodiment 2

[0032] A preparation method of β-hydroxyalkylamide curing agent, comprising the following preparation steps:

[0033] (1) Get four-necked bottle, device mechanical stirring, condenser tube and thermometer, take by weighing dimethyl adipate, diethanolamine and catalyst (diethanolamine and dimethyl adipate mol ratio are 2.4, catalyst and product A weight ratio of 0.14%), added to the reaction flask, heated to 80 ° C and reacted under reduced pressure, stirred for 2 hours, evaporated the volatile methanol, and obtained tetrahydroxyethyl adipamide solution, which was product A;

[0034] (2) The product A was cured in a tray for 9 hours, broken into powder and dried at 95°C. Crushed and dried to obtain white powder solid tetrahydroxyethyl adipamide curing agent.

Embodiment 3

[0036] A preparation method of β-hydroxyalkylamide curing agent, comprising the following preparation steps:

[0037] (1) Get four-necked bottle, device mechanical stirring, condenser tube and thermometer, take diethyl adipate, diethanolamine and catalyst (diethanolamine and dimethyl adipate mol ratio are 2.0, catalyst and product A weight ratio is 0.12%), added to the reaction flask, heated up to 75°C for reaction under reduced pressure, stirred for 2 hours, evaporated the volatile component ethanol, and obtained tetrahydroxyethyl adipamide solution, which was product A;

[0038] (2) The product A was cured in a tray for 8 hours, broken into powder and dried at 100°C. Crushed and dried to obtain white powder solid tetrahydroxyethyl adipamide curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com