Alcohol-based gasoline additive as well as preparation method and application thereof

A technology of alcohol-based gasoline and additives, applied in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of increasing the production cost of alcohol-based gasoline and increasing the difficulty of the production process of alcohol-based gasoline, achieving good industrial application prospects, The effect of improving anti-oxidation performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 100 parts of dimethyl adipate, 30 parts of pentylbicyclohexylphenol and 50 parts of oleic acid were reacted for 1.5 hours at a temperature of 73°C under vacuum conditions; 3 parts of imine, the reaction temperature is 55°C, the reaction is 0.5 hour, the yield is 98%, and the additive of the present invention is obtained.

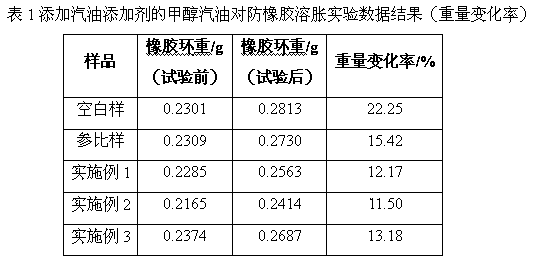

[0032] The test results of rubber swelling resistance and anti-corrosion performance of methanol gasoline with the above additives are shown in Tables 1-3, wherein the reference sample is methanol gasoline without additives.

Embodiment 2

[0034] 100 parts of dimethyl adipate, 30 parts of pentylbicyclohexylphenol and 60 parts of oleic acid were reacted for 1.5 hours at a temperature of 75°C under vacuum conditions; 4 parts of imine, the reaction temperature is 55°C, the reaction is 0.5 hour, the yield is 99%, and the additive of the present invention is obtained.

[0035] Table 1-3 shows the test results of rubber swelling resistance and corrosion resistance of methanol gasoline with the above additives.

Embodiment 3

[0037] 100 parts of dimethyl adipate, 35 parts of pentylbicyclohexylphenol and 65 parts of oleic acid were reacted for 1.5 hours at a temperature of 75°C under vacuum conditions; 4 parts of imine, the reaction temperature is 55°C, the reaction is 0.5 hour, the yield is 97%, and the additive of the present invention is obtained.

[0038] Table 1-3 shows the test results of rubber swelling resistance and corrosion resistance of methanol gasoline with the above additives.

[0039] Anti-swelling and anti-corrosion performance tests of rubber

[0040] The ratio of methanol gasoline to additives is 1:0.0001~0.0008.

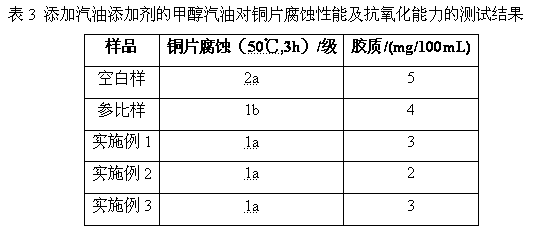

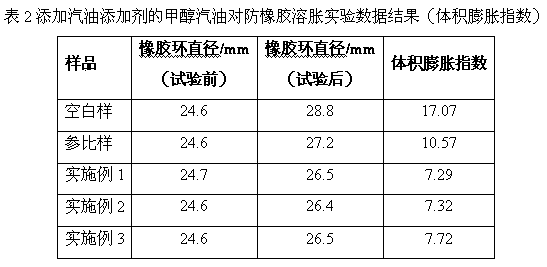

[0041] Tables 1 and 2 list the experimental data and test conditions of the gasoline additive anti-rubber swelling of the present invention.

[0042] Material: nitrile rubber ring Temperature: 50°C

[0043] Sample: 500ppm metering + M40 methanol gasoline

[0044]

[0045]

[0046] The data in the table shows that the present invention has a good inhibitory e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com