Environmentally-friendly synthesis method of dimethyl adipate

A green synthesis technology of dimethyl adipate, which is applied in the field of green synthesis of dimethyl adipate, can solve the problems that the catalyst cannot be recycled and reused, the preparation is difficult, and the equipment is corroded, so as to break the limitation of thermodynamic equilibrium, The effect of ensuring product yield and improving esterification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

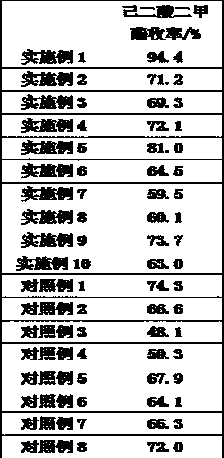

Examples

Embodiment 1

[0016] Step 1. Accurately weigh 0.48mol of copper nitrate, 0.24mol of 50wt% manganese nitrate solution, and 0.96mol of 30wt% silica sol, dissolve them in 500g deionized water, and configure the metal salt solution;

[0017] Step 2. Stir the above salt solution and 1M ammonium bicarbonate aqueous solution precipitant at 50°C, co-precipitate in parallel, and the precipitation pH=6.0 and the precipitation time is 1h;

[0018] Step 3. Aging for 1 hour after precipitation, the precipitate was washed and filtered, dried at 110°C for 24 hours, and calcined at 450°C for 5 hours to obtain a catalyst sample;

[0019] Step 4, add a small amount of zeolite to prevent bumping in the three-necked flask of the tower kettle, open the cooling water switch of the tower top condenser and the tower kettle control power supply, and adjust the voltage to be stable;

[0020] Step 5. Accurately weigh 1 mol of adipic acid and 10 mol of methanol to prepare a reaction raw material with an alcohol / acid s...

Embodiment 2

[0027] Step 5. Accurately weigh 1 mol of adipic acid and 9 mol of methanol to prepare a raw material with an alcohol / acid ratio of 9, and weigh a certain amount of raw material in a three-neck flask with a balance accurate to one thousandth ; All the other steps are with embodiment 1.

Embodiment 3

[0029] Step 5. Accurately weigh 1 mol of adipic acid and 8 mol of methanol to prepare a raw material with an alcohol / acid ratio of 8, and weigh a certain amount of raw material in a three-neck flask with a balance accurate to one thousandth ; All the other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com