Method for purifying diacid dimethyl esters by plate distillation separation

A technology of dimethyl dibasic acid and dimethyl succinate, which is applied in the field of separation and purification of organic mixtures, can solve the problems of high production cost, complex production process and large investment in equipment, and reduce energy consumption and product quality. The effect of stable and uniform quality and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

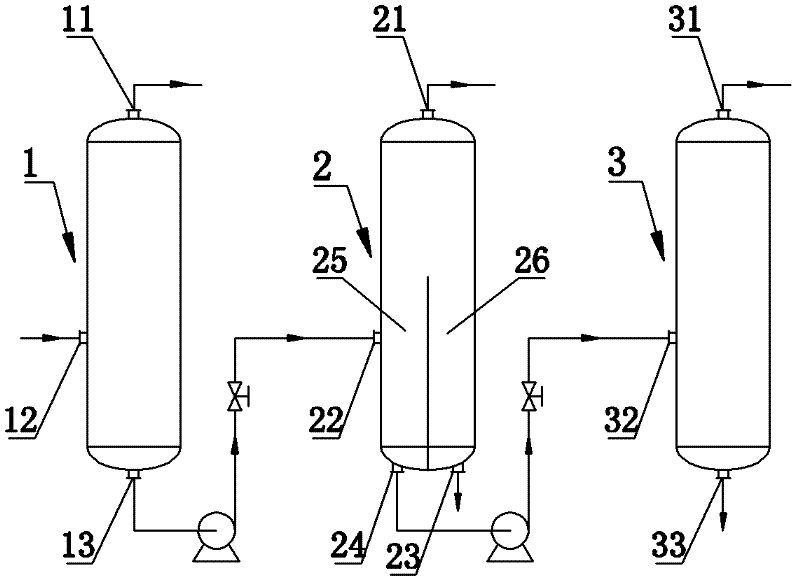

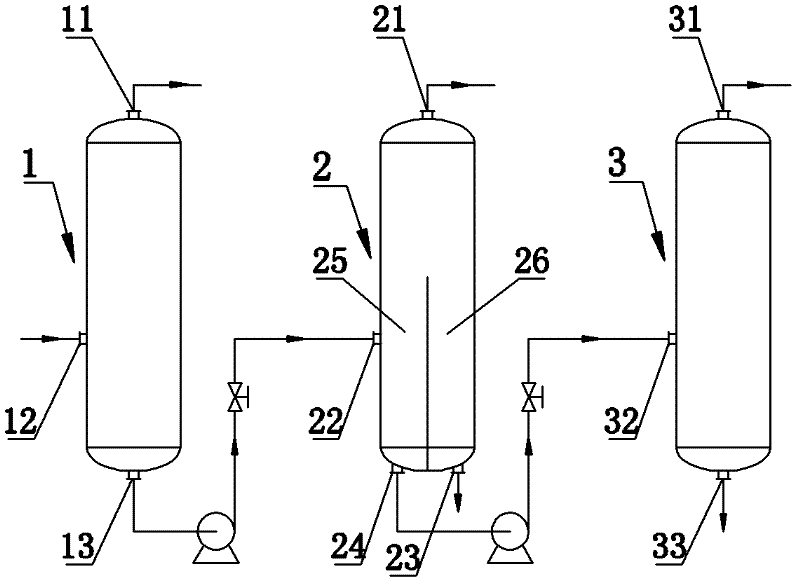

[0021] The raw material dimethyl mixed diacid passes through three distillation towers connected in series in sequence, and first enters the first distillation tower connected in series. The pressure inside the first distillation tower is 20kPa, the gas phase temperature at the top of the tower is 95°C, and the temperature at the bottom of the tower is 115°C. ℃, the light component is separated from the top of the first distillation tower, and the bottom material enters the second distillation tower. The bottom of the second distillation tower is vertically equipped with a partition to divide the lower cavity of the second distillation tower into The first tower chamber on one side and the second tower chamber on the other side, and the material inlet of the second distillation tower is located below the top of the partition, the pressure inside the second distillation tower is 18kPa, and the gas phase temperature at the top of the tower is 100°C , the temperature at the bottom...

Embodiment 2

[0023] Dimethyl mixed diacid as the raw material passes through three distillation towers connected in series, and first enters the first distillation tower connected in series. The internal pressure of the first distillation tower is 22kPa, the gas phase temperature at the top of the tower is 100°C, and the temperature at the bottom of the tower is 120°C. ℃, the light component is separated from the top of the first distillation tower, and the bottom material enters the second distillation tower. The bottom of the second distillation tower is vertically equipped with a partition to divide the lower cavity of the second distillation tower into The first tower chamber on one side and the second tower chamber on the other side, and the material inlet of the second distillation tower is located below the top of the partition, the pressure inside the second distillation tower is 19kPa, and the gas phase temperature at the top of the tower is 105°C , the temperature at the bottom of...

Embodiment 3

[0025] The raw material mixed diacid dimethyl ester passes through three distillation towers connected in series in turn, and first enters the first distillation tower connected in series. The pressure inside the first distillation tower is 23kPa, the gas phase temperature at the top of the tower is 105°C, and the temperature at the bottom of the tower is 130°C. ℃, the light component is separated from the top of the first distillation tower, and the bottom material enters the second distillation tower. The bottom of the second distillation tower is vertically equipped with a partition to divide the lower cavity of the second distillation tower into The first tower chamber on one side and the second tower chamber on the other side, and the material inlet of the second distillation tower is located below the top of the partition, the pressure inside the second distillation tower is 20kPa, and the gas phase temperature at the top of the tower is 110°C , the temperature at the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com