Membrane dryer, intermittent esterification reaction system and dimethyl adipate preparation method

A technology of esterification reaction and dryer, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, etc., can solve problems affecting the conversion rate of adipic acid, etc., and achieve the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

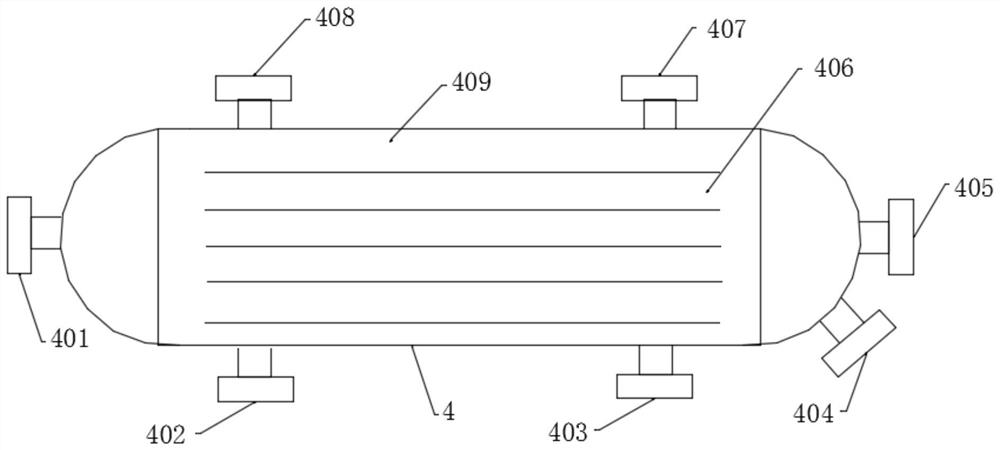

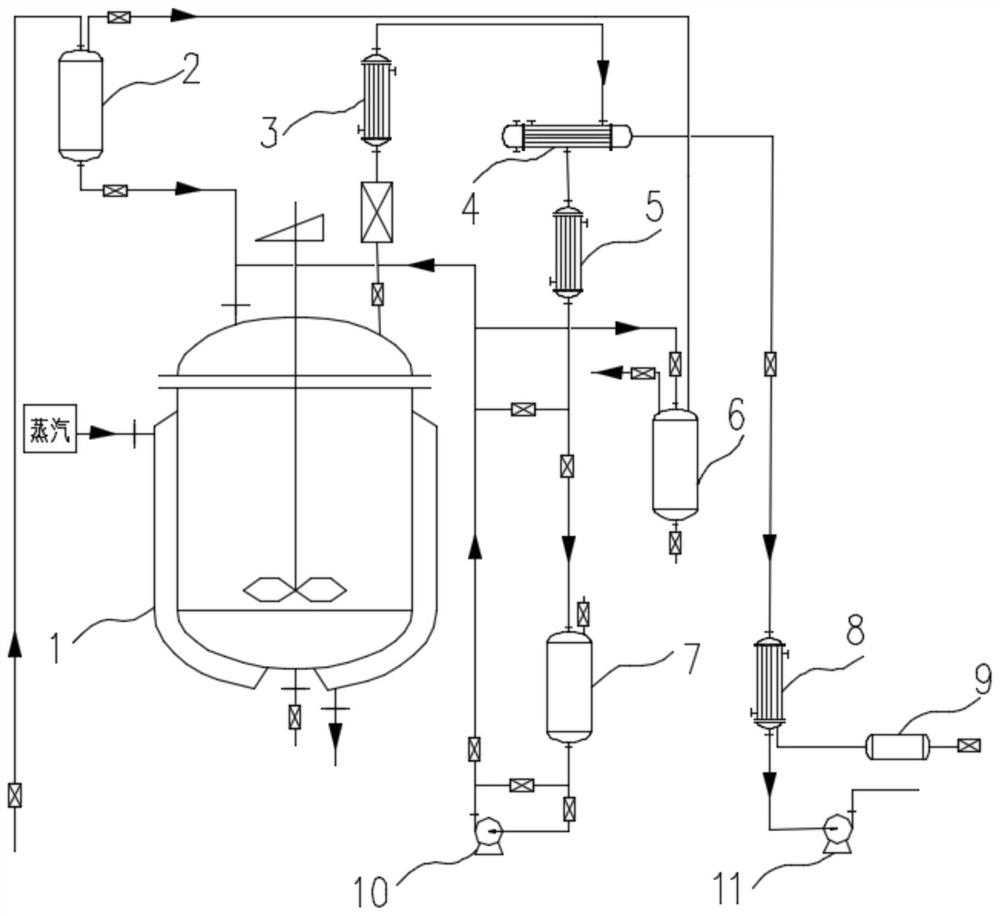

[0053] Such as figure 2 As shown, further, an embodiment of the present invention also provides a kind of dimethyl adipate preparation method, adopts above-mentioned intermittent esterification reaction system, described dimethyl adipate preparation method ( figure 2 Arrow in the schematically represents the flow chart of described dimethyl adipate preparation side) specifically comprises the following steps: add methanol and catalyst in reaction kettle 1, add oxalic acid after heating and carry out esterification reaction, simultaneously pass through preliminary The heater 3 heats the mixture of methanol vapor and water vapor produced during the esterification reaction, and then transports it to the membrane dryer 4 to remove the water in the mixture of methanol vapor and water vapor produced during the esterification reaction. Steam to obtain dry methanol vapor, and then condense the methanol vapor through the condenser 5, so as to transport the methanol vapor to the react...

Embodiment 1

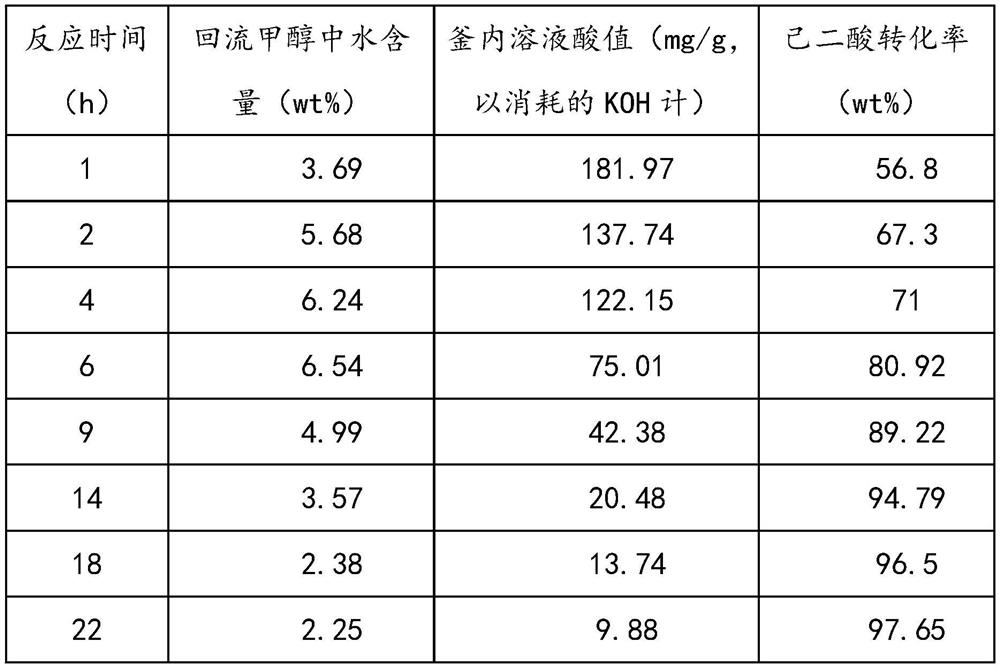

[0058] Using the above-mentioned intermittent esterification reaction system, a 2000L enamel kettle was used as the reaction kettle 1. After cleaning and drying with methanol, 250kg of methanol and 25kg of catalyst were added. Turn on stirring and heat the kettle with steam. When the temperature in the kettle is 60°C, add 250kg of adipic acid from the manhole. Turn on the vacuum pump 11 and turn on the reflux pump 10, and control the temperature of the reflux methanol between 30-35°C. After the adipic acid is completely dissolved, increase the steam pressure to keep the temperature in the kettle at about 80°C. By adjusting the kettle temperature and the temperature of the preheater 3, the reflux methanol flow through the membrane dryer 4 is controlled. Monitor 1h, 2h, 4h, 6h, 9h, 14h, 18h, 22h in the reflux methanol water content and the acid value of the solution in the kettle. The water content in the methanol is detected by gas chromatography, and the acid value of the s...

Embodiment 2

[0063]Using the above-mentioned intermittent esterification reaction system, a 2000L enamel kettle was used as the reaction kettle 1. After cleaning and drying with methanol, 250kg of methanol and 25kg of catalyst were added. Turn on stirring and heat the kettle with steam. When the temperature in the kettle is 60°C, add 250kg of adipic acid from the manhole. Turn on the vacuum pump 11 and turn on the reflux pump 10, and control the temperature of the reflux methanol between 30-35°C. After the adipic acid is completely dissolved, increase the steam pressure to keep the temperature in the kettle at about 100°C. By adjusting the kettle temperature and the temperature of the preheater 3, the reflux methanol flow through the membrane dryer 4 is controlled. Monitor 1h, 2h, 4h, 6h, 9h, 14h, 18h, 22h in the reflux methanol water content and the acid value of the solution in the kettle. The water content in the methanol is detected by gas chromatography, and the acid value of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com