Method for preparing 1,6-hexylene glycol through dimethyl adipate gas-phase hydrogenation

A technology of dimethyl adipate and hexanediol, which is applied in the field of organic synthesis and catalyst preparation, can solve the problems of poor selectivity of noble metal catalysts, harsh catalytic reaction conditions, and complicated preparation processes, so as to increase the number of effective active sites and reduce Pressure requirement, effect of improving catalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Cu / HPS catalyst I with a mass fraction of Cu of 20% was firstly prepared according to the above method.

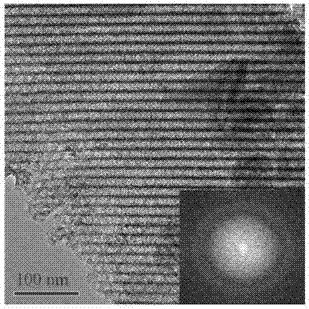

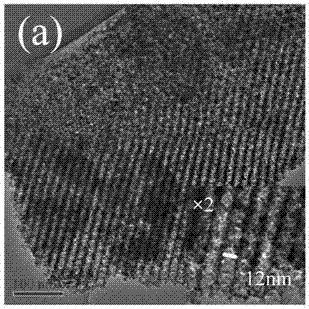

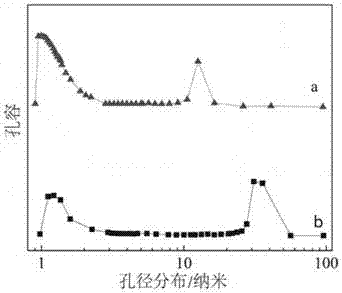

[0031]The operation steps are as follows: prepare 100ml of 1mol / L HCl solution, put it into a 250ml flask and bathe it to 15°C. 1gF127, 2.5gKCl and 1.2gTMB were added sequentially. Stir at 15°C for 1h. 4.16g TEOS was added dropwise to the flask. Then stirred at 15°C for 24h. The suspension was transferred to a stainless steel crystallization kettle for crystallization at 100°C for 24h. Filter the crystallized liquid, dry the filter cake and bake it at 500°C to obtain a white solid that is hierarchical porous SiO 2 Carrier (HPS).

[0032] Weigh an appropriate amount of carrier, take 0.774g Cu(NO 3 ) 2 ·3H 2 O and 2.7ml of ammonia water are configured into copper ammonia solution, and 0.82g of HPS carrier is added and 2.7ml of water is added. After aging at room temperature for 4 hours, the temperature was raised to distill ammonia until the pH of the solutio...

Embodiment 2

[0039] Prepare 100ml of 1mol / L HCl solution and add it to a 250ml flask in a water bath to 15°C. 1gF127, 2.5gKCl and 1.2gTMB were added sequentially. Stir at 15°C for 1h. 4.16 g of TEOS was added dropwise to the flask. Then stirred at 15°C for 24h. The suspension was transferred to a stainless steel crystallization kettle for crystallization at 140°C for 24h. The crystallized liquid is filtered, and the filter cake is dried and calcined at 500°C. The obtained white solid is hierarchically porous SiO 2 Carrier HPS.

[0040] Weigh an appropriate amount of carrier, take 0.857gCu(NO 3 ) 2 ·3H 2 O and 2.9ml ammonia water are configured into copper ammonia solution, add 0.908g HPS carrier and add 2.9ml water. After aging at room temperature for 4 hours, the temperature was raised to distill ammonia until the pH of the solution was less than 7. After filtering and washing, the obtained filter cake was dried. Roast at 400°C for 4h. The prepared catalyst with a loading capa...

Embodiment 3

[0046] Prepare 100ml of 1mol / L HCl solution and add it to a 250ml flask in a water bath to 15°C. 1gF127, 2.5gKCl and 1.2gTMB were added sequentially. Stir at 15°C for 1h. 4.16 g of TEOS was added dropwise to the flask. Then stirred at 15°C for 24h. The suspension was transferred to a stainless steel crystallization kettle for crystallization at 100°C for 24h. The crystallized liquid is filtered, and the filter cake is dried and calcined at 500°C. The obtained white solid is hierarchical porous SiO 2 Carrier HPS.

[0047] Weigh an appropriate amount of carrier, take 0.944gCu(NO 3 ) 2 ·3H 2 O and 3.3ml of ammonia water are configured into copper ammonia solution, and 1g of HPS carrier is added and 3.3ml of water is added. After aging at room temperature for 4 hours, the temperature was raised to distill ammonia until the pH of the solution was less than 7. After filtering and washing, the obtained filter cake was dried. Roast at 400°C for 4h. The prepared catalyst wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com