Continuous esterification reaction system, production method of dimethyl adipate and application

A technology of dimethyl adipate and esterification, applied in chemical instruments and methods, separation/purification of carboxylic acid esters, separation methods, etc., can solve problems such as high energy consumption and increased production costs, and reach a broad market foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

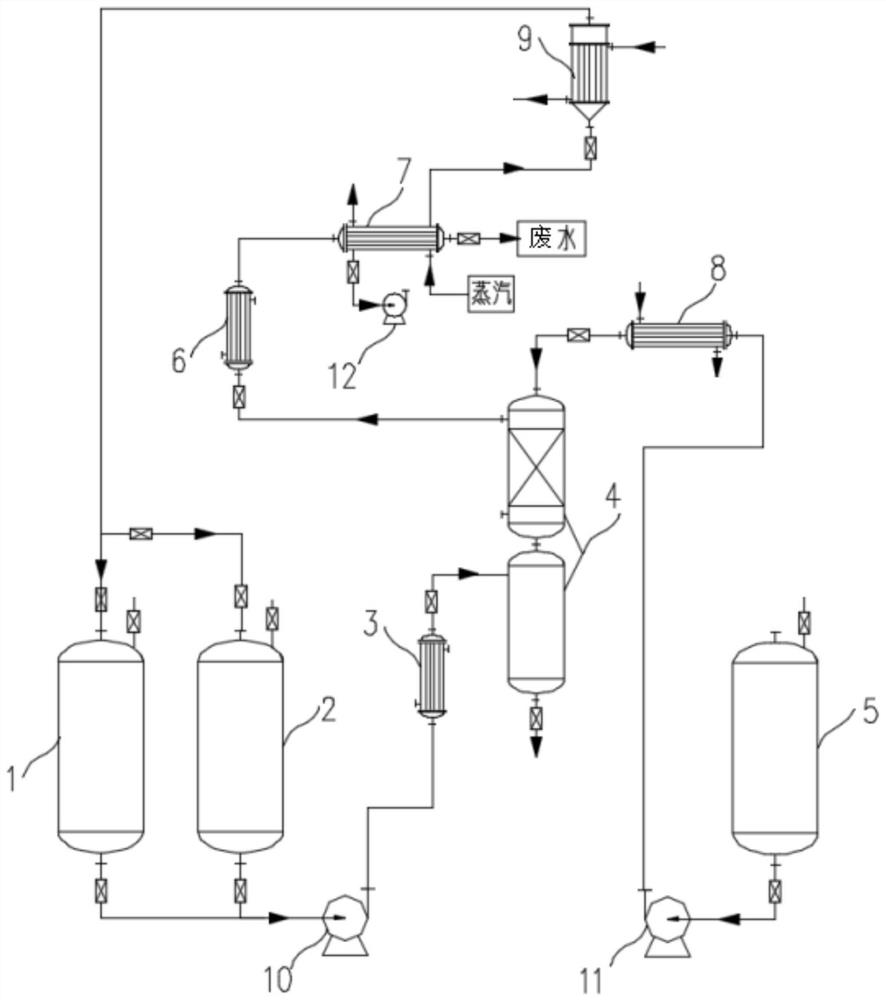

Embodiment 1

[0062] A kind of production method of dimethyl adipate, comprises the following steps: adopt above-mentioned continuous esterification reaction system (but membrane drier 7 is not provided with), transport by the product that the intermittent esterification method reacts 4 hours to generate after filtration To the material tank 5, as the pre-esterification liquid (the conversion rate of adipic acid in the pre-esterification liquid is 73.5%) is heated by the material preheater 8, and the heating temperature is 95°C. The pre-esterification liquid is added from the top of the esterification tower 4 according to the flow rate of 4L / h. Use a hydraulic diaphragm metering pump to pump methanol into the methanol vaporizer 3 at a flow rate of 9L / h, heat it to 99°C and then enter the esterification tower 4 in the same direction as the pre-esterification liquid. After 2 hours of reaction, the liquid level of the dimethyl adipate buffer tank of the esterification tower 4 began to appear. ...

Embodiment 2

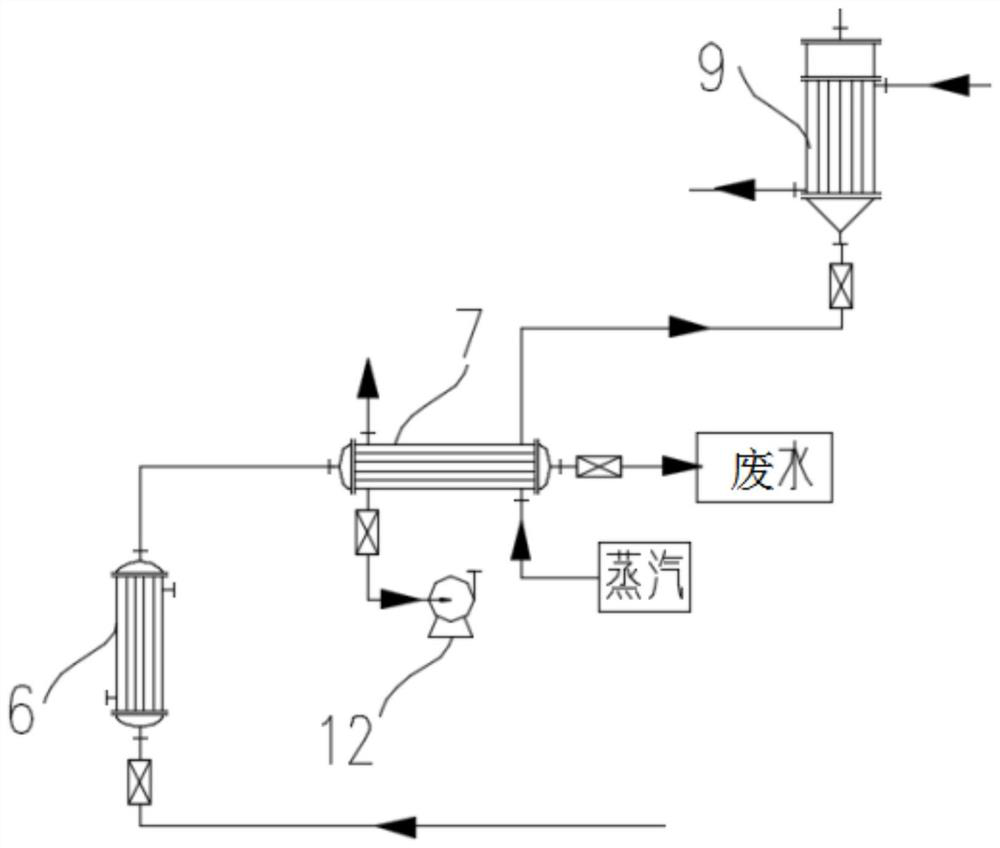

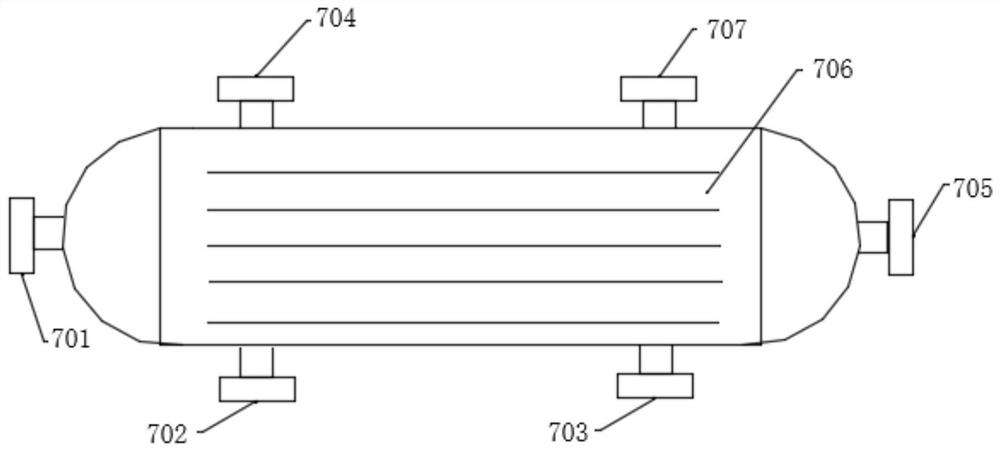

[0064]A kind of production method of dimethyl adipate, comprises the following steps: adopt above-mentioned continuous esterification reaction system (membrane drier 7 is provided with), by the product filtration that batch esterification method generates for 4 hours after conveying to The material tank 5 is heated by the material preheater 8 as a pre-esterification liquid (the conversion rate of adipic acid in the pre-esterification liquid is 73.5%), and the heating temperature is 95°C. The pre-esterification liquid is added from the top of the esterification tower 4 according to the flow rate of 4L / h. Esterification tower 4 is 2000mm high, and the path is 240mm, and distributor is equipped with at the upper end, and catalyst addition is 5kg. Use a hydraulic diaphragm metering pump to pump methanol into the methanol vaporizer 3 at a flow rate of 9L / h, heat it to 99°C and then enter the esterification tower 4 in the same direction as the pre-esterification liquid. After react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com