Method for producing dimethyl adipate from adipic acid

A technology of dimethyl adipate and adipic acid, applied in the field of adipic acid to produce dimethyl adipate, can solve the problem of discontinuous pre-esterification, inability to continuously feed, unstable composition of pre-esterified products, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

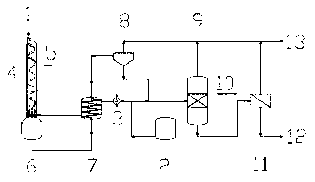

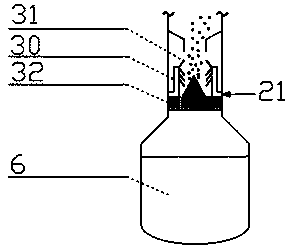

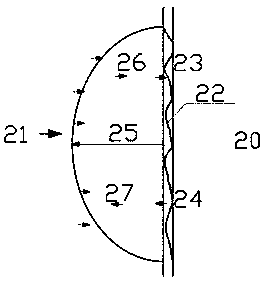

Method used

Image

Examples

Embodiment 1

[0041] Put 14.6Kg of adipic acid particles in the reaction tower, pass through nitrogen to replace the air, heat methanol into steam at the bottom of the reaction tower, control the steam pressure to 1.08MPa, and purify the adipic acid with methanol through the nozzle. The acid dissolves rapidly, and the dissolution rate of adipic acid is controlled by controlling the amount of methanol vapor to ensure that the temperature of the solution in the tower kettle is 80°C. Pass the tower kettle solution into the heat exchanger for pre-esterification reaction, the reaction temperature is 140°C, and the space velocity is 0.25h -1 , the reaction pressure is the saturated vapor pressure of methanol. After the reaction, the conversion rate of adipic acid is 97.2%, and the content of dimethyl adipate is 37.3%. After entering the double esterification reactor, the double esterification reaction is carried out on the catalyst bed. The reaction temperature is 120°C, the reaction pressure is ...

Embodiment 2

[0043] Put 14.6Kg of adipic acid particles in the reaction tower, pass through nitrogen to replace the air, heat methanol into steam at the bottom of the reaction tower, control the steam pressure to 1.0MPa, and purify the adipic acid with methanol through the nozzle. The acid dissolves rapidly, and the dissolution rate of adipic acid is controlled by controlling the amount of methanol vapor to ensure that the temperature of the solution in the tower kettle is 78°C. Pass the tower kettle solution into the heat exchanger for pre-esterification reaction, the reaction temperature is 140°C, and the space velocity is 0.2h -1 , the reaction pressure is the saturated vapor pressure of methanol. After the reaction, the conversion rate of adipic acid is 97.2%, and the content of dimethyl adipate is 35.2%. After entering the double esterification reactor, the double esterification reaction is carried out on the catalyst bed, The reaction temperature is 120°C, the reaction pressure is 4....

Embodiment 3

[0045] Put 14.6Kg of adipic acid particles in the reaction tower, pass through nitrogen to replace the air, heat methanol into steam at the bottom of the reaction tower, control the steam pressure to 0.9MPa, and purify the adipic acid with methanol through the nozzle. The acid dissolves quickly, and the dissolution rate of adipic acid is controlled by controlling the amount of methanol vapor to ensure that the solution temperature in the tower kettle is 75°C. Pass the tower kettle solution into the heat exchanger for pre-esterification reaction, the reaction temperature is 140°C, and the space velocity is 0.2h -1 , the reaction pressure is the saturated vapor pressure of methanol. After the reaction, the conversion rate of adipic acid is 97.2%, and the content of dimethyl adipate is 33.7%. After entering the double esterification reactor, the double esterification reaction is carried out on the catalyst bed. The reaction temperature is 120°C, the reaction pressure is 4.0MPa, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com