Method and equipment for continuous esterification production of adipic acid dimethyl ester

A technology of dimethyl adipate and adipic acid is applied in the field of continuous esterification to produce dimethyl adipate and equipment, and can solve problems such as pollution and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

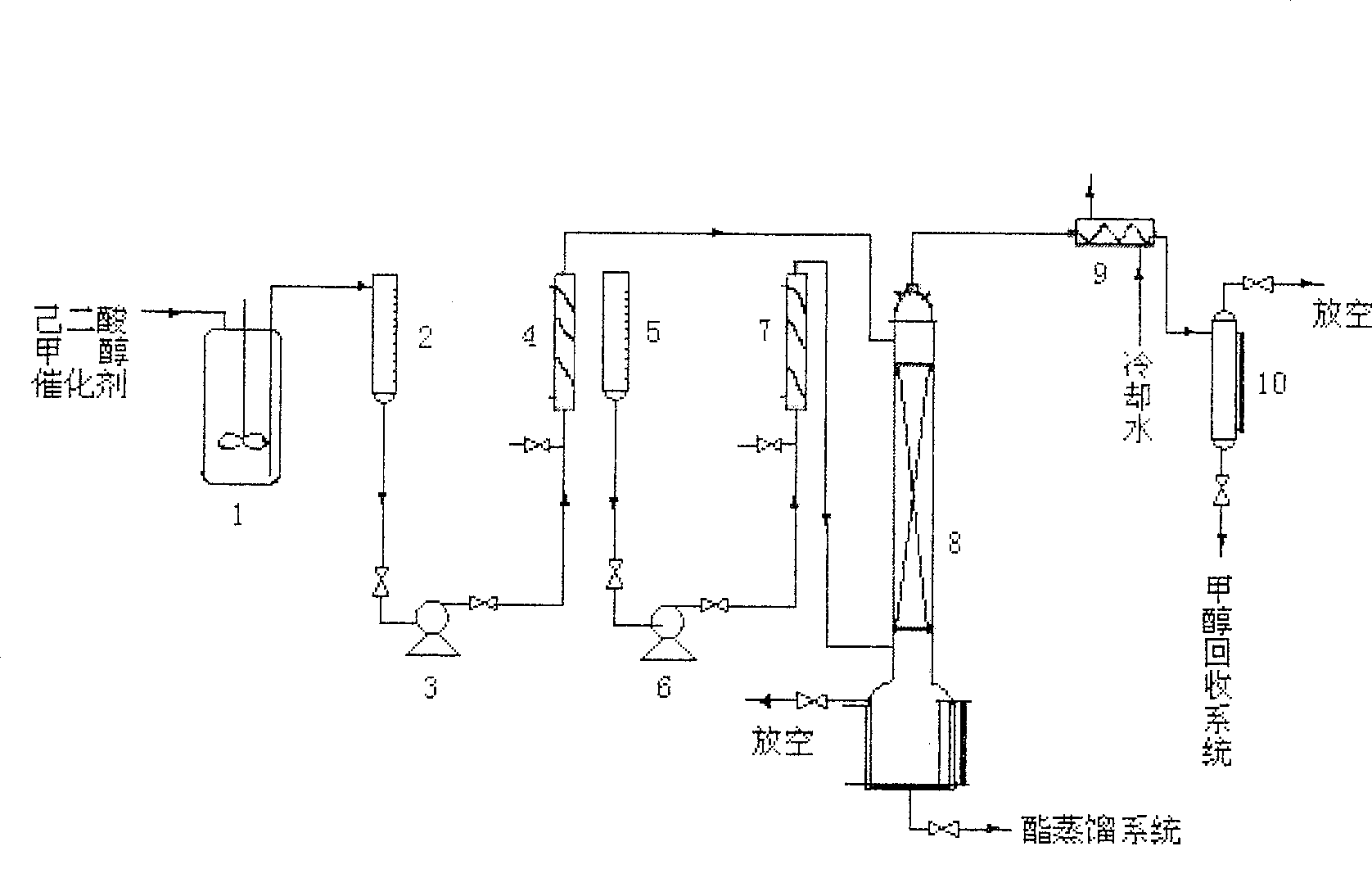

[0025] The used equipment of the inventive method comprises pre-esterification kettle (1), raw material tank (2), raw material pump (3), preheater (4), methanol tank (5), methanol pump (6), vaporizer (7), Continuous esterification tower (8), condenser (9), storage tank (10);

[0026] The pre-esterification kettle equipped with agitator is connected to the feed port of the raw material tank through the pipeline, the discharge port of the raw material tank is connected to the feed port of the raw material pump through the pipeline, and the discharge port of the raw material pump is connected to the pre-esterification tank through the pipeline. The feed port of the heater is connected, and the discharge port of the preheater is connected with the feed port on the upper part of the continuous esterification tower through a pipeline;

[0027] The methanol tank is connected to the inlet of the methanol pump through the pipeline, the outlet of the methanol pump is connected to the in...

Embodiment 5-6

[0038] Utilize the pre-esterification product of embodiment 1, 2 to carry out continuous esterification, normal pressure, under the condition of 70~150 ℃, liquid space velocity is 0.34Kg / Kg h, concrete result is as follows:

[0039] Table 3 Experimental results of continuous esterification with different methanol space velocities

[0040] liquid space velocity

Embodiment 7-8

[0042] Utilize the product of embodiment 3,4 pre-esterification to carry out continuous esterification, normal pressure, under the condition of 70~150 ℃, methanol space velocity is 0.37Kg / Kg h, concrete result is as follows:

[0043] Table 4 Experimental results of continuous esterification with different liquid space velocities

[0044] liquid space velocity

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com