Production system and method of sec-butyl acetate

A sec-butyl acetate and production method technology, applied in the field of sec-butyl acetate production system, can solve the problems of incomplete butene conversion, low butene conversion rate, high difficulty in utilization, etc., and achieve easy realization and selectivity High, the effect of simplifying the separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

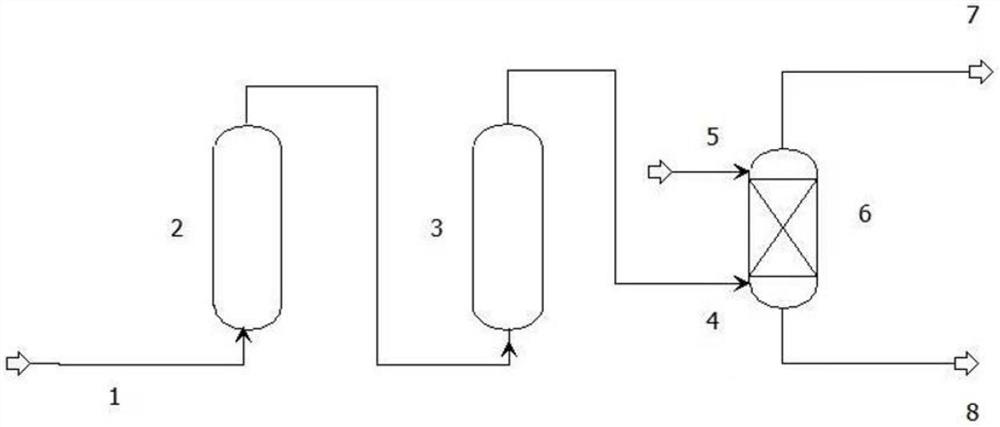

[0033] A production system of sec-butyl acetate, such as figure 1 As shown, it includes: the first fixed bed reactor 2, the second fixed bed reactor 3 and the catalytic rectification tower 6 connected in series in sequence;

[0034] Wherein, the catalytic rectification column comprises an acetic acid supplement port 5, a top discharge port 7 and a column bottom discharge port 8, and the acetic acid supplement port 5 is located at the top of the catalytic distillation column 6.

[0035] The catalytic rectification column sequentially includes a rectifying section, a reaction section and a stripping section from the bottom of the column to the top of the column;

[0036] in,

[0037] There are 20-30 theoretical plates in the rectification section, 8-12 theoretical plates in the reaction section, and 10-20 theoretical plates in the stripping section.

[0038] A production method of sec-butyl acetate, utilizing the above-mentioned production system of sec-butyl acetate to react,...

Embodiment 2

[0044] A kind of production method of sec-butyl acetate, different from embodiment 1 is:

[0045]In step (1), the DB757 high temperature resistant resin catalyst is loaded in the first fixed bed reactor, the reaction temperature is set to 100°C, the pressure is 2.0Mpa, and the space velocity is 2h -1 ;

[0046] In step (2), the second fixed bed reactor is filled with D005 and D006, wherein the reaction temperature is 80°C, the pressure is 1.0-2.0Mpa, and the space velocity is 1-4h -1 ;

[0047] In the step (3), the reaction section of the catalytic rectification tower is set to have a tower top temperature of 60°C, a reaction section temperature of 90°C, a tower still temperature of 182°C, a pressure of 0.6Mpa, and a reflux ratio of 3.0.

[0048] The final total butene conversion was 92.53%, and the sec-butene acetate selectivity was 97.19%.

Embodiment 3

[0050] A kind of production method of sec-butyl acetate, different from embodiment 1 is:

[0051] In step (1), the first fixed bed reactor is filled with DA330 high temperature resistant resin catalyst, the reaction temperature is set to 90°C, the pressure is 1.2Mpa, and the space velocity is 3h -1 ;

[0052] In step (2), the reaction temperature in the second fixed bed reactor is 75°C, the pressure is 1.0-2.0Mpa, and the space velocity is 1-4h -1 ;

[0053] In step (3), the reaction section of the catalytic rectification tower is filled with CDM module catalyst, and the temperature at the top of the column is set to be 50°C, the temperature of the reaction section is 80°C, the temperature of the tower still is 175°C, the pressure is 0.5Mpa, and the reflux ratio is 2.0.

[0054] The final total butene conversion was 94.19%, and the sec-butene acetate selectivity was 98.55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com