Method for separating mixed diacid dimethyl ester

A technology of dimethyl dibasic acid and dimethyl succinate, which is applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of difficult industrialization, high energy consumption and large equipment investment. and other problems, to achieve the effect of high energy utilization, high separation efficiency, and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

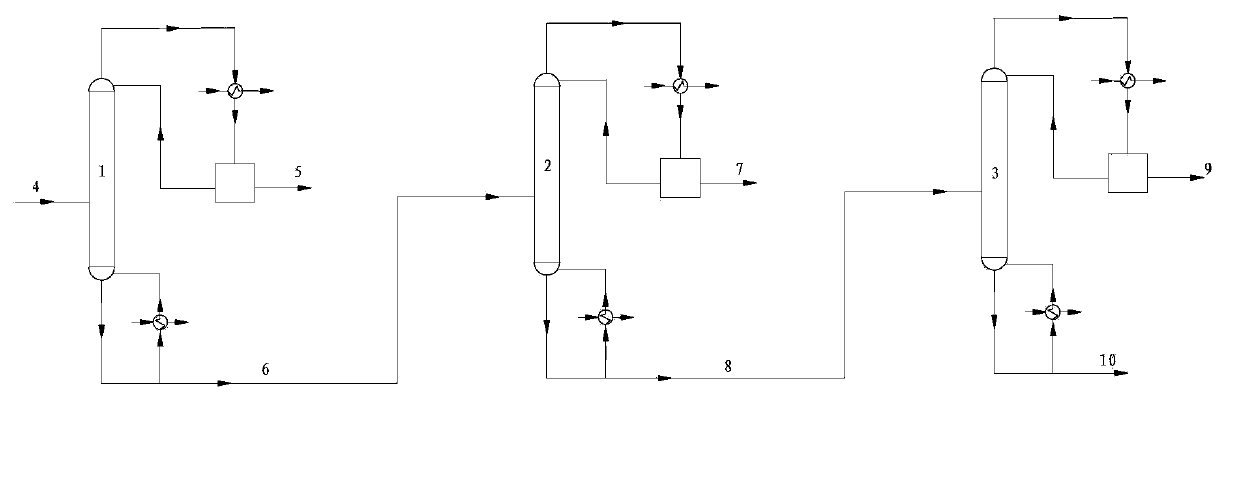

Image

Examples

Embodiment 1

[0034] The process separates dimethyl succinate, dimethyl glutarate and dimethyl adipate from mixed dimethyl dibasic acids. The separation method is carried out according to the above-mentioned three-tower continuous rectification process. The content of each substance in the mixed dibasic acid dimethyl ester raw material used in example 1 is as follows: dimethyl malonate 0.2wt%, dimethyl succinate 16.1wt%, dimethyl glutarate 53.2wt%, hexanoate Dimethyl diacid is 30.1wt%, and there are 0.4wt% high-boiling impurities.

[0035] The conditions of each column of continuous rectification are as follows:

[0036] The dimethyl succinate rectification column, that is, the rectification 1 column, has 16 actual trays (including the reboiler), and the feed position is the eighth tray from the top.

[0037] The control parameters of the dimethyl succinate rectification tower, that is, the rectification 1 tower, are as follows: about 115°C of the feed temperature, about 96°C of the tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com