Preparation method for high-hardness water-based glass baking paint

A glass baking varnish, high hardness technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of uneven mixing, poor wear resistance, and difficult construction at the construction site, and achieve simple construction, excellent wear resistance, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

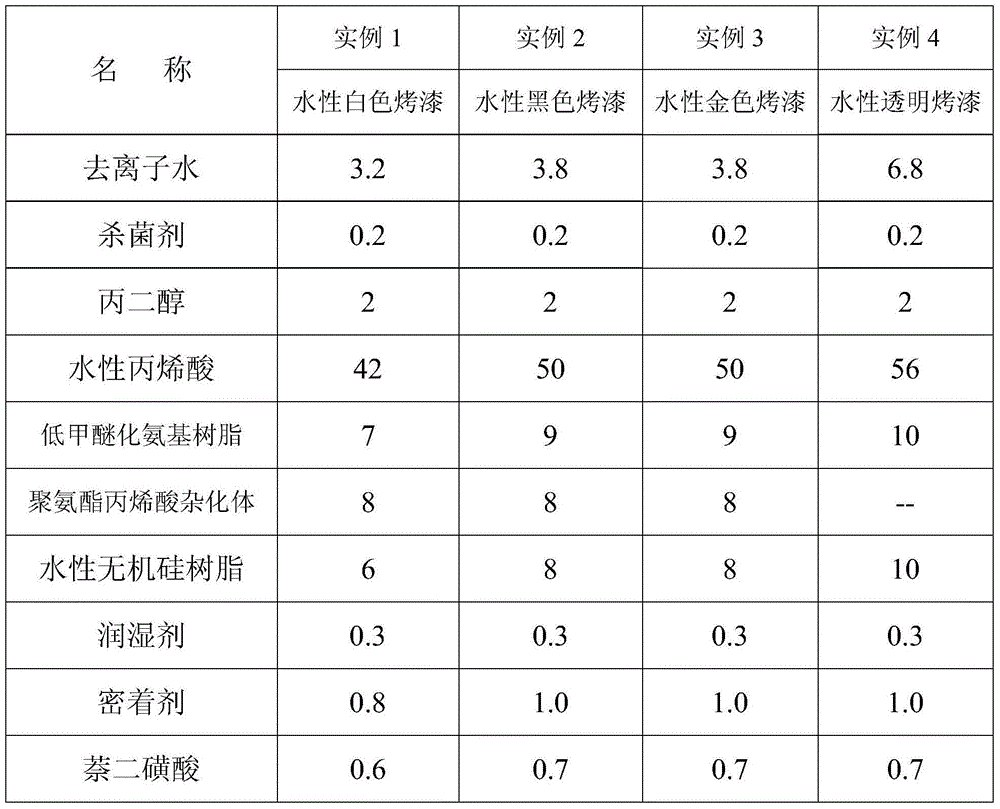

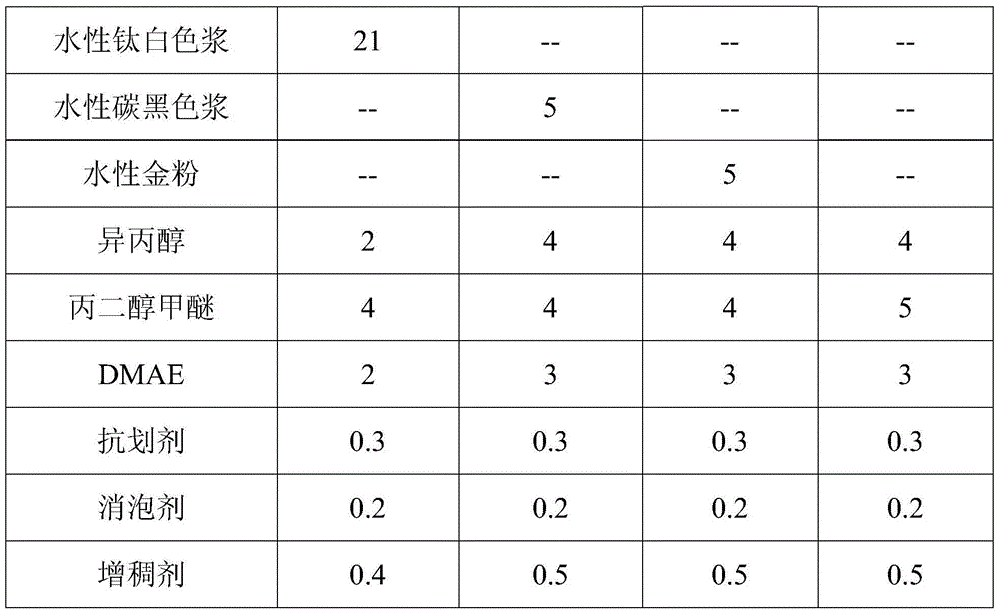

Embodiment 1

[0024] According to the high hardness water-based white glass baking paint in Example 1 in Table 1, add deionized water into the dispersing kettle according to the weight ratio of the formula, add bactericide, propylene glycol, wetting agent, adhesive agent, and acid catalyst under stirring and disperse for 30-40 minutes. Add water-based acrylic resin, amino resin, water-based polyurethane acrylic hybrid, water-based inorganic silicone resin and stir evenly, add water-based titanium white slurry, PH regulator, defoamer, and then add film-forming aids, leveling agents, and thickeners at a uniform speed. Thickener, stirring to adjust the viscosity and pH value, that is, a high-hardness water-based white glass baking varnish is prepared.

Embodiment 2

[0026] Example 2 Refer to Example 1 for the preparation steps of high-hardness water-based black glass baking varnish.

Embodiment 3

[0028] Example 3 Refer to Example 1 for the preparation steps of the high-hardness water-based golden glass baking varnish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com