Porous high-entropy alloy self-supporting electrode for electrolyzing water and preparation method thereof

A self-supporting electrode, high-entropy alloy technology, applied in the field of electrolysis of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a high-entropy alloy-based electrolytic water catalyst, comprising the following steps:

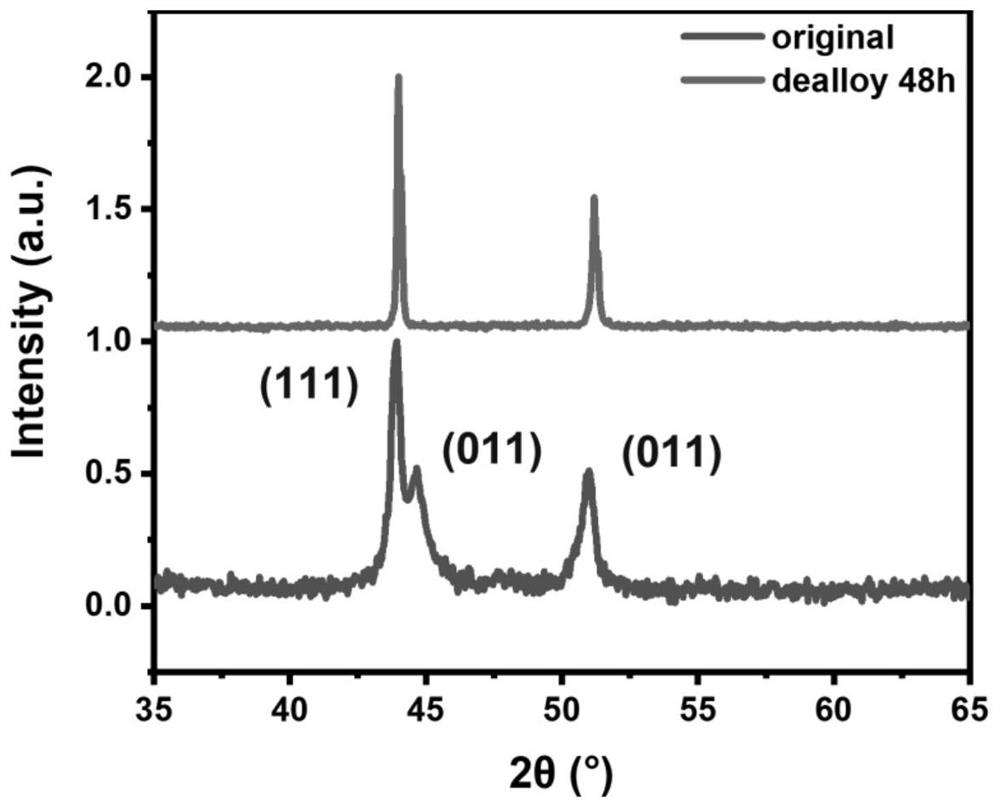

[0032] 1) Melting and mixing nickel powder, cobalt powder, chromium powder, iron powder, aluminum powder and tungsten powder (the molar ratio of which is 30:30:10:10:18:2), and cooling to form a eutectic structure (FCC phase + B2 phase) high-entropy alloy;

[0033] 2) Use a wire cutting machine to cut an area of 1×1cm from a large ingot 2 , a square sheet with a thickness of 400 μm, simply polished by a grinding and polishing machine to remove the surface oxide skin, and the thickness is about 300 μm at this time;

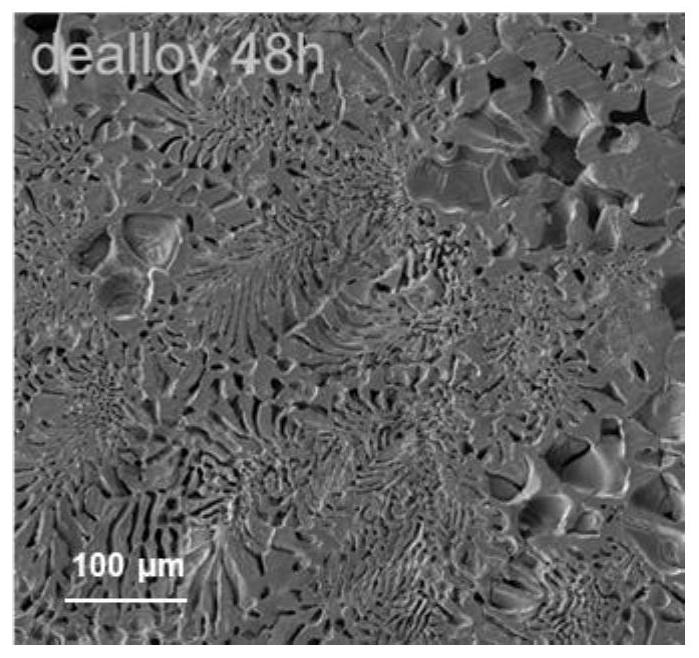

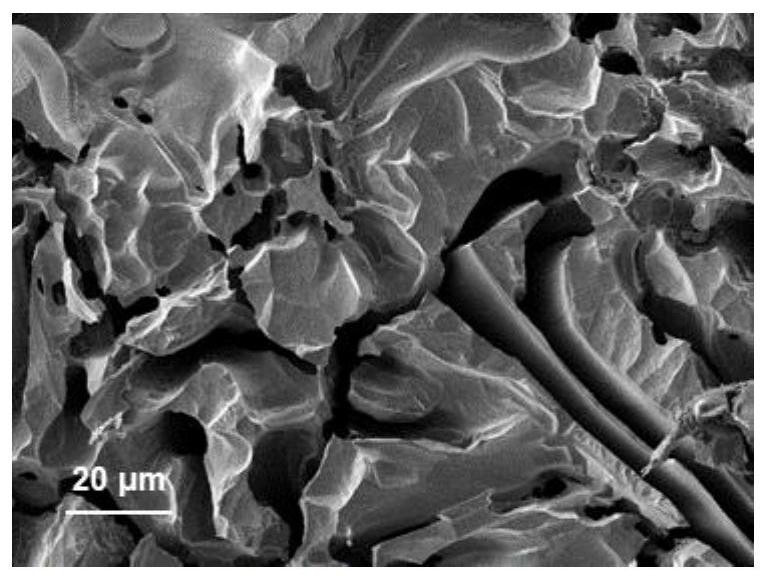

[0034] 3) Take 30mL of 1M HCl solution and pipette it into a 50mL centrifuge tube, put a piece of high-entropy alloy sheet into it, soak for 6, 12, 24, 48, 60, and 72h for dealloying treatment; the mass fraction of HCl solution is Anything below 20% is fine.

[0035] 4) After the hydrochloric acid dealloying treatment i...

Embodiment 1

[0038] Raw material components and dosage are as follows:

[0039] Nickel powder, cobalt powder, chromium powder, iron powder, aluminum powder, tungsten powder (the molar ratio is 30:30:10:10:18:2), hydrochloric acid solution (concentration is 1mol / L), potassium hydroxide solution ( The concentration is 1mol / L).

[0040] The preparation technology of this high-entropy alloy-based catalyst:

[0041] Melt and mix nickel powder, cobalt powder, chromium powder, iron powder, aluminum powder, tungsten powder (the molar ratio is 30:30:10:10:18:2), and form a two-phase eutectic structure (FCC) after cooling. phase + B2 phase) of high-entropy alloys; using a wire cutting machine to cut an area of 1 × 1cm from a large ingot 2 , a square sheet with a thickness of 400 μm, and the surface oxide skin was simply polished by a grinding and polishing machine, and the thickness was about 300 μm at this time; take 30mL of 1M HCl corrosion solution and pipette it into a 50mL centrifuge tube, ...

Embodiment 2

[0056] Raw material components and dosage are as follows:

[0057] Nickel powder, cobalt powder, chromium powder, iron powder, aluminum powder, tungsten powder (the molar ratio is 25:20:20:15:15:5), hydrochloric acid solution (concentration is 2mol / L), potassium hydroxide solution ( The concentration is 1mol / L).

[0058] The preparation technology of this high-entropy alloy-based catalyst:

[0059] Melt and mix nickel powder, cobalt powder, chromium powder, iron powder, aluminum powder, tungsten powder (the molar ratio is 25:20:20:15:15:5), and form a two-phase eutectic structure (FCC) after cooling phase + B2 phase) of high-entropy alloys; using a wire cutting machine to cut an area of 1 × 1cm from a large ingot 2 , a square sheet with a thickness of 400 μm, and the surface oxide scale was simply polished by a grinding and polishing machine, and the thickness was about 300 μm at this time; take 30mL of 2M HCl corrosion solution and pipette it into a 50mL centrifuge tube, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com