Polyester resin composition and molded article of same

A technology of polyester resin and composition, which is applied in the field of polyester resin composition containing glycolic acid resin and its molded body, which can solve the problem that the decomposition speed is not necessarily sufficient, and achieve the effect of excellent decomposability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

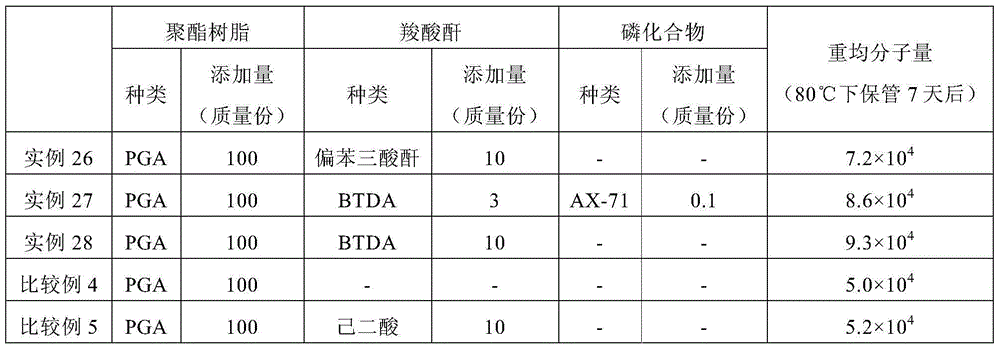

[0098] Hereinafter, the present invention will be described more specifically based on examples and comparative examples, but the present invention is not limited to the following examples. The properties of the resins used in the Examples, the obtained polyester resin compositions, and the like were measured by the following methods.

[0099]

[0100] The molecular weight of the resin (polyglycolic acid, polylactic acid, etc.) was determined by gel permeation chromatography (GPC) under the following conditions.

[0101] (GPC measurement conditions)

[0102] Device: "Shodex-104" manufactured by Showa Denko Co., Ltd.

[0103] Column: 2 pieces of HFIP-606M connected in series with 1 piece of HFIP-G as pre-column

[0104] Column temperature: 40°C

[0105] Mobile phase: Hexafluoroisopropanol (HFIP) solution dissolved with 5 mM sodium trifluoroacetate

[0106] Flow rate: 0.6ml / min

[0107] Detector: RI (Differential Refractive Index) detector

[0108] Molecular weight calib...

example 1

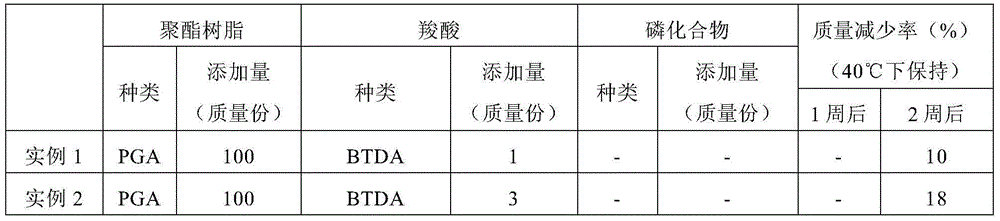

[0118]Add 1 part by mass of 3,3',4,4'-benzophenonetetraacid dianhydride ( BTDA), supplied to the feed section of a two-screw kneading extruder (manufactured by Toyo Seiki Co., Ltd. "2D25S") with a screw temperature of 200-240°C, and melted and kneaded to obtain polyglycolic acid in the form of pellets resin composition. With respect to this polyglycolic acid resin composition, a decomposition test was performed according to the method described above, and the mass loss rate after holding at 40° C. for 2 weeks was determined. The results are shown in Table 1.

[0119] [Example 2-6]

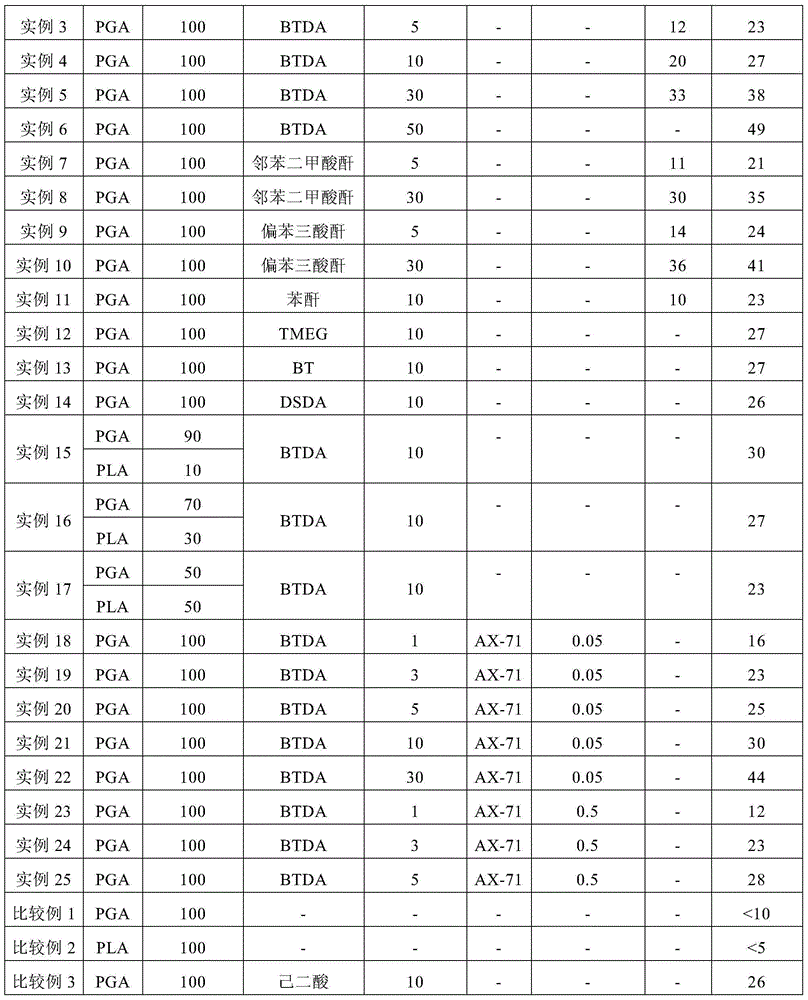

[0120] Except that the addition amount of BTDA was changed into the amount shown in Table 1, all the others were the same as Example 1, and were prepared into a pellet-like polyglycolic acid resin composition. The obtained polyglycolic acid resin composition was subjected to a decomposition test according to the method described above, and the mass loss rate after holding at 40° C. for 1 week (E...

example 11-14

[0126] In addition to adding 100 parts by mass of phthalic anhydride (Example 11), ethylene glycol double anhydro trimellitate (TMEG) (Example 12), dianhydride butane tetracarboxylic acid (BT) (Example 13), or phenyl sulfone tetra Carboxylic acid dianhydride (DSDA) (Example 14) is used to replace BTDA, and all the other are the same as Example 1, and are prepared into a pellet-like polyglycolic acid resin composition. The obtained polyglycolic acid resin composition was subjected to a decomposition test according to the method described above, and the mass loss rate after holding at 40° C. for 1 week (Example 11) and 2 weeks (Examples 11-14) was determined. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com