Preparation method of natural benzaldehyde by ozone collaborative heterogeneous catalysis of cinnamaldehyde or cinnamon oil

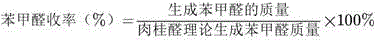

A technology of benzaldehyde and cinnamon oil is applied in the directions of ozone decomposition preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc. It can solve the problems of difficult contact with materials, etc., to achieve the effect of high reusability, good selectivity and yield, and high utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take by weighing 16.86g of barium nitrate and 18.25g of tin chloride dihydrate and dissolve them in deionized water to make a solution with a concentration of 0.2mol / L; similarly, take 32.39g of ammonium bicarbonate and dissolve them in deionized water to make A solution with a concentration of 0.4mol / L. At a water bath temperature of 40°C and a speed of 300 rpm, the barium nitrate and tin chloride solutions prepared above were added dropwise to the ammonium bicarbonate solution by co-current co-precipitation method, and the solution changed from clear to turbid. When the temperature is 7 to 8, stop adding the metal salt solution dropwise, wait for the precipitate to age in the mother liquor at a constant temperature of 40° C. for 10 hours, and then carry out suction filtration to obtain the precipitate. The obtained precipitate was dried at 90°C for 12h, and calcined at 950°C for 2h to obtain the BaO / SnO catalyst. In the bubbling reactor, add 4.91g cinnamaldehyde (the...

Embodiment 2

[0024] Take by weighing 17.86g nickel nitrate hexahydrate, 18.97g tin chloride dihydrate and be dissolved in deionized water respectively, be made into the solution that concentration is 0.2mol / L; Similarly, take by weighing 24.59g ammonium bicarbonate and dissolve in deionized water, Dubbed a solution with a concentration of 0.4mol / L. At a water bath temperature of 40°C and a speed of 300 rpm, the nickel nitrate and tin chloride solutions prepared above were added dropwise to the ammonium bicarbonate solution by co-current co-precipitation method, and the solution changed from clear to turbid. When the temperature is 7-8, stop adding the metal salt solution dropwise, wait for the precipitate to age in the mother liquor at a constant temperature of 40° C. for 6 hours, and then carry out suction filtration to obtain the precipitate. The obtained precipitate was dried at 90°C for 12h and calcined at 600°C for 4h to obtain the NiO / SnO catalyst. In the bubble reactor, add 5.06g o...

Embodiment 3

[0026] Take by weighing 18.26g tin chloride dihydrate, 19.82g lanthanum nitrate hexahydrate and be dissolved in deionized water respectively, be made into the solution that concentration is 0.05mol / L; Similarly, take by weighing 22.39g ammonium bicarbonate and dissolve in deionized water, Dubbed a solution with a concentration of 0.3mol / L. At a water bath temperature of 40°C and a rotational speed of 300 rpm, the above-prepared lanthanum nitrate and tin chloride solutions were added dropwise to the ammonium bicarbonate solution by co-current co-precipitation method, and the solution changed from clear to turbid. When the temperature is 7 to 8, stop adding the metal salt solution dropwise, wait for the precipitate to age in the mother liquor at a constant temperature of 40°C for 2 hours, and then carry out suction filtration to obtain the precipitate. The obtained precipitate was dried at 90°C for 20h, and calcined at 700°C for 5h to obtain La 2 o 3 / SnO catalyst. In the bub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com