A kind of method for preparing cellulose solution

A technology of cellulose solution and cellulose solvent, which is applied in the field of cellulose solvent, can solve the problems of high production cost, side reaction, high dissolution temperature, etc., and achieve the effects of environmental friendliness, comprehensive cost, less pollution, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

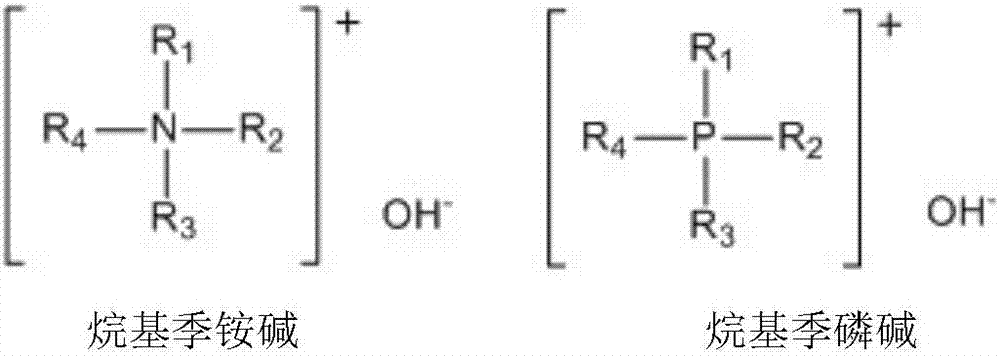

Method used

Image

Examples

Embodiment Construction

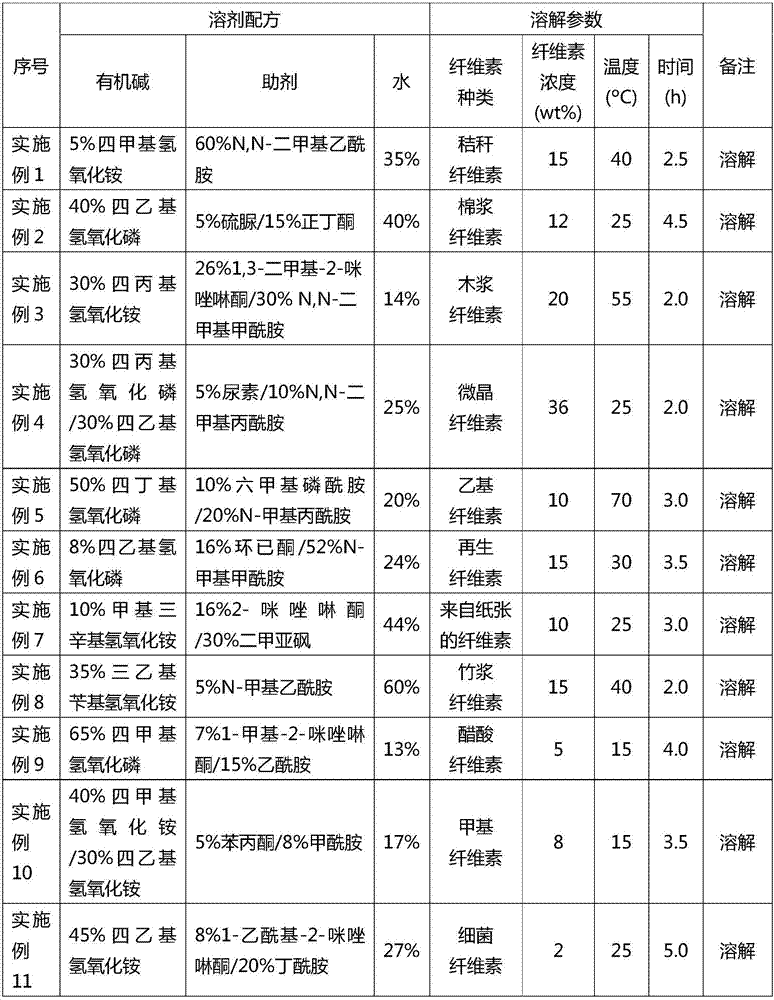

[0022] Specific examples and comparative examples of the present invention are given below to further illustrate the technical solution of the present invention. The process parameters of embodiment and comparative example are shown in Table 1, and its general process steps are as follows:

[0023] Firstly, the cellulose solvent is prepared, and each component of the solvent is configured according to the formula and added into a container, and a homogeneous mixed solution is formed by mechanical stirring at 25°C. Then add a certain amount of cellulose into the solvent system, and stir at a certain temperature for a certain time to obtain a cellulose solution.

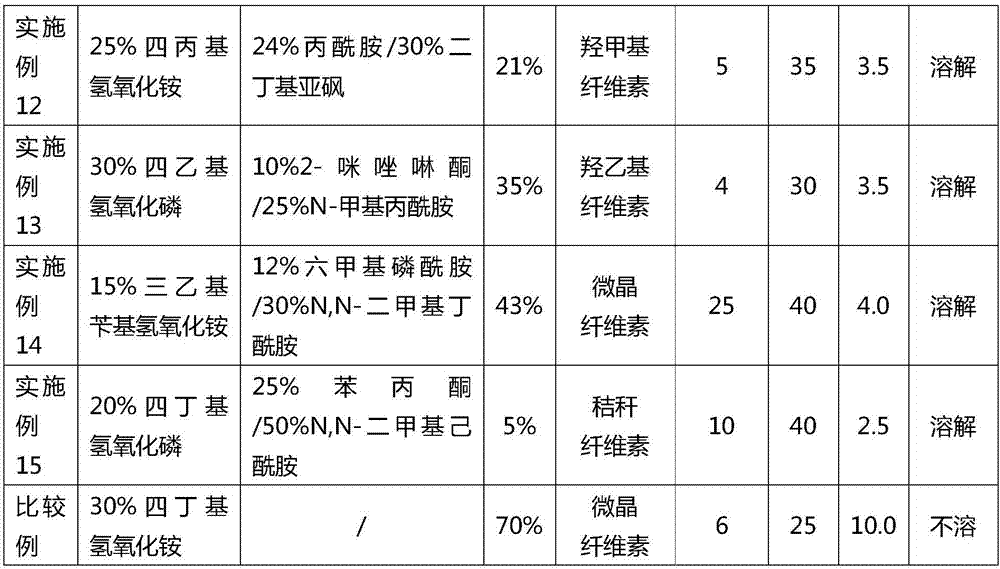

[0024] Table 1. Embodiment and comparative example technological condition parameter list

[0025]

[0026]

[0027] In the table, "dissolved" means that an optically clear cellulose solution was obtained, and "insoluble" means that a cloudy cellulose solution was obtained.

[0028] The solubility of cellulose ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com