Preparation method of silicon oxide nanosheet composite ternary positive electrode material for lithium battery

A ternary lithium battery and cathode material technology, applied in battery electrodes, positive electrodes, nanotechnology and other directions, can solve the problems of poor effect, unstable ternary cathode material structure, complicated modification process, etc., to improve structural stability , The preparation process is simple and controllable, and the structure is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

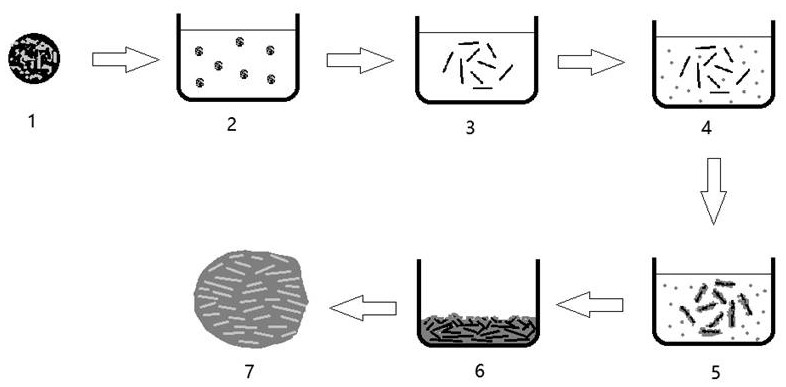

[0035] (1) Add 15kg of silicon-lithium alloy powder into 90kg of absolute ethanol and 45kg of isopropanol, and disperse evenly to obtain a silicon-lithium alloy dispersion;

[0036] (2) The silicon-lithium alloy dispersion was placed in an ice-water bath and stirred slowly, with the speed controlled at 200 rpm, until the reaction was complete until no bubbles were generated, and the nano-silicon wafer dispersion was obtained;

[0037] (3) Add 70kg of nickel acetate, 25kg of cobalt acetate, and 25kg of manganese acetate into 650kg of deionized water and mix evenly to obtain a mixed solution, and then mix evenly with 150kg of nano-silicon chip dispersion to obtain a metal salt / nano-silicon chip mixed solution;

[0038] (4) Slowly stir the metal salt / nano-silicon flakes mixed solution at a speed of 200rpm for 2.5h, then add ammonia water to adjust the pH value to 10, and then let it stand for 2.5h to obtain a coprecipitate-coated silicon nanoflake solution, and then Rotary evapor...

Embodiment 2

[0041] (1) Add 12kg of silicon-lithium alloy powder into 95kg of absolute ethanol and 42kg of isopropanol, and disperse evenly to obtain a silicon-lithium alloy dispersion;

[0042] (2) Place the silicon-lithium alloy dispersion in an ice-water bath and stir slowly, with the speed controlled at 150 rpm, until the reaction is complete until no bubbles are generated, and the nano-silicon wafer dispersion is obtained;

[0043] (3) Add 60kg of nickel acetate, 20kg of cobalt acetate, and 20kg of manganese acetate into 700kg of deionized water and mix evenly to obtain a mixed solution, then mix evenly with 149kg of nano-silicon chip dispersion to obtain a metal salt / nano-silicon chip mixed solution;

[0044] (4) Slowly stir the metal salt / nano-silicon flakes mixed solution at a speed of 200rpm for 3h, then add ammonia water to adjust the pH value to 9.5, and then let it stand for 2h to obtain a co-precipitate-coated silicon nanoflake solution, and then rotary evaporate Solvent to ob...

Embodiment 3

[0047] (1) Add 18kg of silicon-lithium alloy powder into 88kg of absolute ethanol and 48kg of isopropanol, and disperse evenly to obtain a silicon-lithium alloy dispersion;

[0048] (2) Place the silicon-lithium alloy dispersion in an ice-water bath and stir slowly, with the speed controlled at 250 rpm, until the reaction is complete until no bubbles are generated, and the nano-silicon wafer dispersion is obtained;

[0049] (3) Add 90kg of nickel acetate, 30kg of cobalt acetate, and 30kg of manganese acetate into 600kg of deionized water and mix evenly to obtain a mixed solution, and then mix evenly with 154kg of nano-silicon chip dispersion to obtain a metal salt / nano-silicon chip mixed solution;

[0050] (4) Slowly stir the metal salt / nano-silicon flakes mixed solution at a speed of 250rpm for 2h, then add ammonia water to adjust the pH value to 10.5, and then let it stand for 3h to obtain a co-precipitate-coated silicon nanoflake solution, and then rotary evaporate Solvent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com