Method for preparing lithium ion battery silicon-carbon composite negative electrode material by taking konjac flour as carbon source

A technology for lithium-ion batteries and negative electrode materials, which is applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of electrode powdering, capacity attenuation, active material detachment, etc., and achieves mild experimental conditions, simple preparation conditions, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

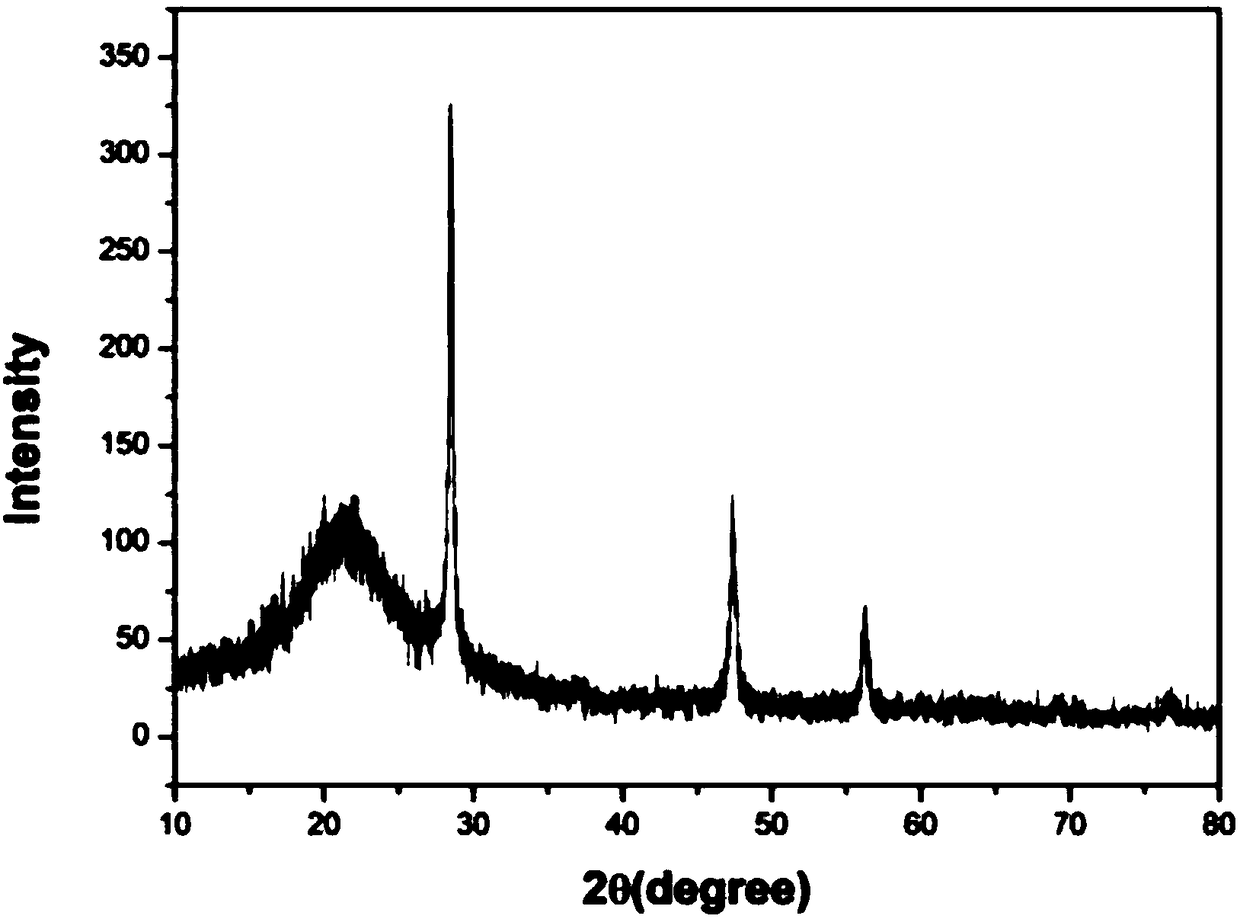

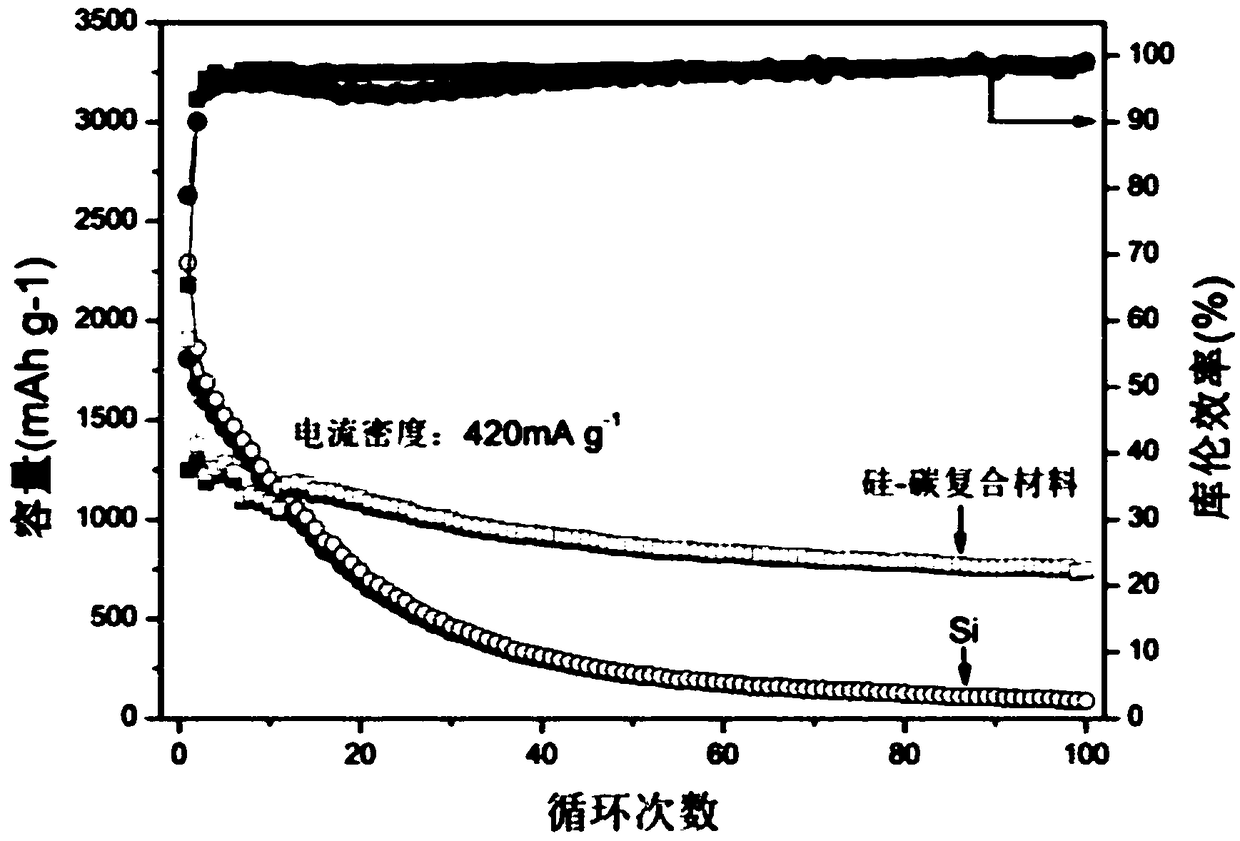

[0030] Embodiment 1: Preparation and characterization of a lithium-ion battery silicon-carbon composite negative electrode material using konjac flour as a carbon source:

[0031] Disperse 0.5g of biomaterial konjac flour into 100ml of deionized water, stir well to obtain a gel-like substance. Disperse 0.5g of silicon powder with a particle size of 200 nanometers into a mixed solution of ethanol and water (volume ratio) at a ratio of 2:1, ultrasonically disperse to obtain a suspension, and slowly add the obtained suspension to the above gel Stir for 6 hours on a magnetic stirrer; place the obtained sample in a drying oven and dry at 100°C for 8 hours, and grind it evenly to obtain a brown-black powder; put the brown-black powder in an inert gas atmosphere at 400°C Keep the temperature for 3 hours, then raise the temperature to 800° C., and keep the temperature for 6 hours to obtain the silicon-carbon composite negative electrode material, which is applied to the lithium-ion ba...

Embodiment 2

[0036] Example 2: Preparation and characterization of a silicon-carbon composite negative electrode material for lithium-ion batteries using konjac flour as a carbon source

[0037] Disperse 0.5g of biomaterial konjac flour into 100ml of deionized water, stir well to obtain a gel-like substance. Disperse 0.5g of silicon powder with a particle size of 500nm into a mixed solution of ethanol and water (volume ratio) at a ratio of 2:1, and ultrasonically disperse to obtain a suspension, which is slowly added to the above gel Stir for 6 hours on a magnetic stirrer; place the obtained sample in a freeze-drying box to dry for 8 hours, and grind it evenly to obtain a brown-black powder; keep the brown-black powder at 400°C for 3 hours in an inert gas atmosphere, and then The temperature was raised to 900° C., and the temperature was kept for 6 hours to obtain a silicon-carbon composite negative electrode material, which was applied to a lithium-ion battery.

Embodiment 3

[0038] Example 3: Preparation and characterization of a silicon-carbon composite negative electrode material for lithium-ion batteries using konjac flour as a carbon source

[0039] Disperse 1 g of konjac flour into 100 ml of deionized water, stir well to obtain a gelatinous substance. Disperse 0.5g of silicon powder with a particle size of 100 nanometers into a mixed solution with a ratio of ethanol and water (volume ratio) of 1:3, ultrasonically disperse to obtain a suspension, and slowly add the obtained suspension to the obtained In the gel-like substance, stir on a magnetic stirrer for 6 hours; place the obtained sample in a drying oven and dry at 100°C for 8 hours, and grind it evenly to obtain a brown-black powder; put the brown-black powder in an inert gas atmosphere at 400°C The temperature was kept for 3 hours under the condition, then the temperature was raised to 700°C, and the temperature was kept for 6 hours to obtain a silicon-carbon composite negative electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com