Adsorptive catalyst and preparation method and application thereof as well as air purification device, and air purification method and application thereof

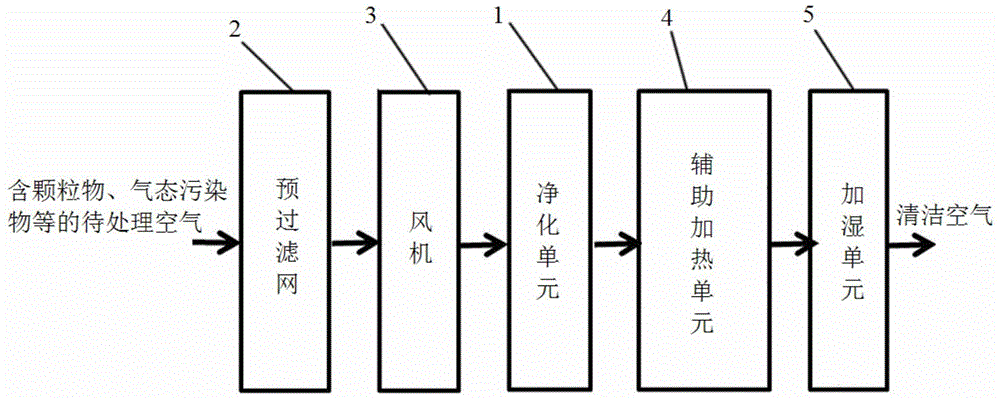

A catalyst and air technology, applied in the field of adsorption catalysts, can solve the problems of low bonding strength of adsorption catalytic components and electric heating carriers, negative catalytic activity of catalysts, etc., and achieve the effects of improving industrial application prospects, good catalytic purification effect, and simplified process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] According to a preferred embodiment of the present invention, the surface of the hydrophobic silica is rich in methyl and / or fluoroalkyl groups, the particle size is 3-15nm, preferably 10-15nm, and the specific surface area is 600-1000m 2 / g, preferably 610-750m 2 / g.

[0036] According to the catalyst of the present invention, it is preferred that the thickness of the coating is 5-1000 μm, preferably 150-1000 μm.

[0037] According to the catalyst of the present invention, the catalytically active component capable of oxidizing gaseous pollutants can be a conventional choice in the art. For the present invention, it is preferred that the catalytically active component capable of oxidizing gaseous pollutants be metal oxides and / or noble metal element, preferably MnO x 、Co 3 o 4 , FeO x , CuO, NiO, TiO 2 、Al 2 o 3 , one or more of Pt, Pd, Au, Ru, Rh and Ag.

[0038] According to one embodiment of the present invention, it is preferred that the catalytically ac...

Embodiment 1

[0081] Preparation of adsorption catalytic catalyst:

[0082] (1) The hydrophobic SiO 2 (The particle size is 14.2nm by laser particle size analyzer, the hydrophobic angle test is 121.1°, and the specific surface area is 615.3m 2 / g), manganese nitrate: the mixture (1:1, weight ratio) of cobalt nitrate (1:1, weight ratio) and dispersant PEG and PVA is made coating;

[0083] (2) With finned aluminum as the structural carrier, the surface of the finned aluminum is cleaned by pickling-alkali washing and water washing, and the finned aluminum is pretreated by anodic oxidation to roughen the surface; The coating is coated on the fin-shaped aluminum by means of pressure spraying, and after drying, it is calcined at 400°C for 2h to obtain the catalyst (the thickness of the coating is 500 μm, and the coating contains 48% by weight of hydrophobic silicon dioxide, 48% by weight active ingredient and 4% by weight of the dispersant, where the hydrophobic SiO 2 The particle size is 14.2...

Embodiment 2

[0088] Preparation of adsorption catalytic catalyst:

[0089] (1) Mix hexamethylsilyl ether, aluminum nitrate and ammonium chloroplatinate (50:1 in molar ratio) and a mixture of dispersant PEG, β-cyclodextrin and hydroxymethyl cellulose (1:1: 1, weight ratio) made into coating;

[0090] (2) Using mullite honeycomb ceramics as the structural carrier, the surface of mullite honeycomb ceramics is cleaned by pickling-alkali washing and water washing, and the coating is coated on the mullite honeycomb ceramics by coating , calcined at 300° C. for 5 h after drying, and reduced with hydrogen at 150° C. for 1 h to obtain a catalyst (the thickness of the coating is 967 μm, the coating contains 80% by weight of hydrophobic silica, 10% by weight of active components and 10% by weight of dispersed agent, the hydrophobic SiO 2 The particle size is 10nm by laser particle size analyzer, the hydrophobic angle is 138.2°, and the specific surface area is 724.5m 2 / g).

[0091] Air purificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com