Motorcycle catalytic converter capable of reaching motorcycle national IV standards and method for preparing motorcycle catalytic converter

A technology for motorcycles and catalytic converters, which is applied in the field of motorcycle catalytic converters and its preparation, can solve the problems that motorcycle exhaust emissions are difficult to meet the National IV standard, the preparation process is complicated, and the catalytic effect is not good, so as to achieve good catalytic effect and preparation The method is simple and the effect is better

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

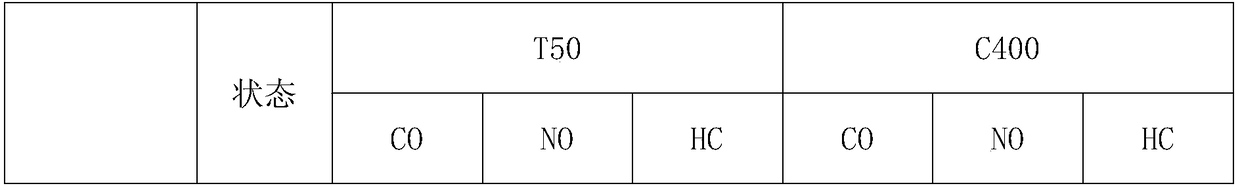

Embodiment 1

[0036] A motorcycle catalytic converter that meets the National IV standard described in this embodiment includes a metal honeycomb carrier and a catalyst coating, wherein the metal honeycomb carrier is an S-type with a specification of Φ20×30 (mm) and a mesh number of 300 cpsi Cellular carrier.

[0037] The catalyst coating, in terms of the total weight of oxides, includes the following components and content: composite modified alumina Ce 15 Zr 5 La 5 Al 75 o 140 Accounting for 19.8597%, modified alumina La-Al 2 o 3 Accounting for 24.8247%, the oxygen storage material Ce 40 Zr 50 La 5 Y 5 o 195 Accounting for 44.6844%, the catalytic active component is a mixture of oxides of Pt, Pd, and Rh, accounting for 0.5844%, 0, and 0.1169%, respectively, and the catalyst promoter is a mixture of oxides of Ce, La, and Zr, accounting for 2.979%, respectively. 0.993%, 1.986%, binder accounted for 3.9719%. The binder is selected from aluminum sol.

[0038] It should be noted t...

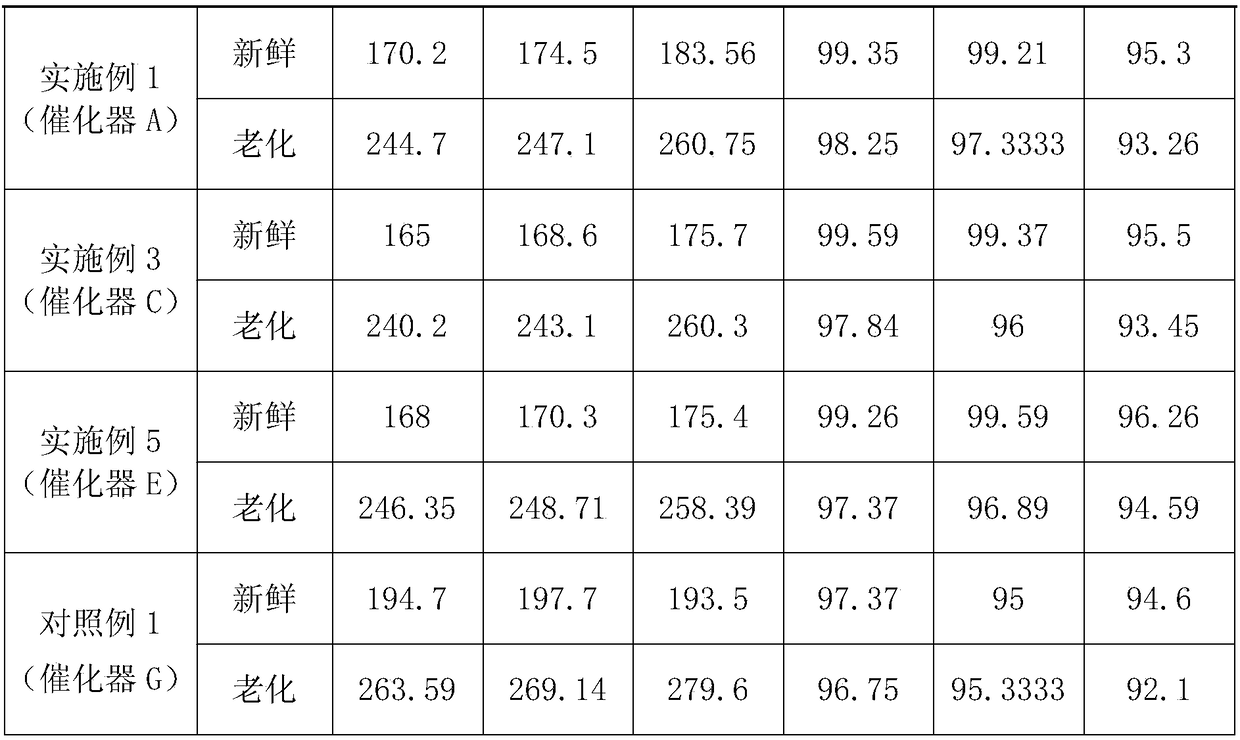

Embodiment 2

[0048] Under other conditions remaining unchanged, select S-shaped metal honeycomb carrier with a specification of Φ42×140 (mm) and a mesh number of 300 cpsi, and similarly prepare catalytic converter B.

Embodiment 3

[0050] Same as catalyst A, change the composition of composite modified alumina to Ce 20 Zr 10 La 5 Al 65 o 165 , in the same way to make catalytic converter C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com