Preparation method of pulullan-animal esterase composite nanofiber

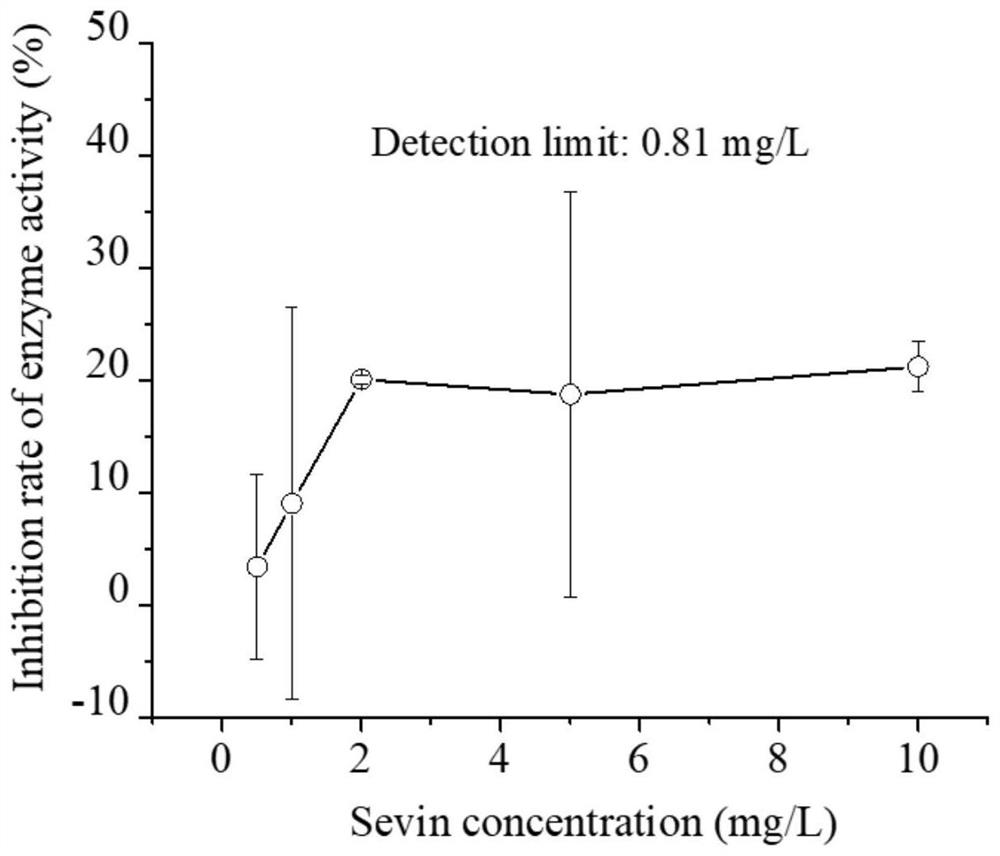

A technology of composite nanofibers and pullulan, applied in fiber treatment, hydrolytic enzymes, immobilized on/in organic carriers, etc., can solve the problems of difficult re-collection, decreased catalytic activity of enzymes, and insensitivity to pesticide responses, etc. problems, to achieve the effect of simple equipment and preparation process, good effect, and sensitive response to pesticides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

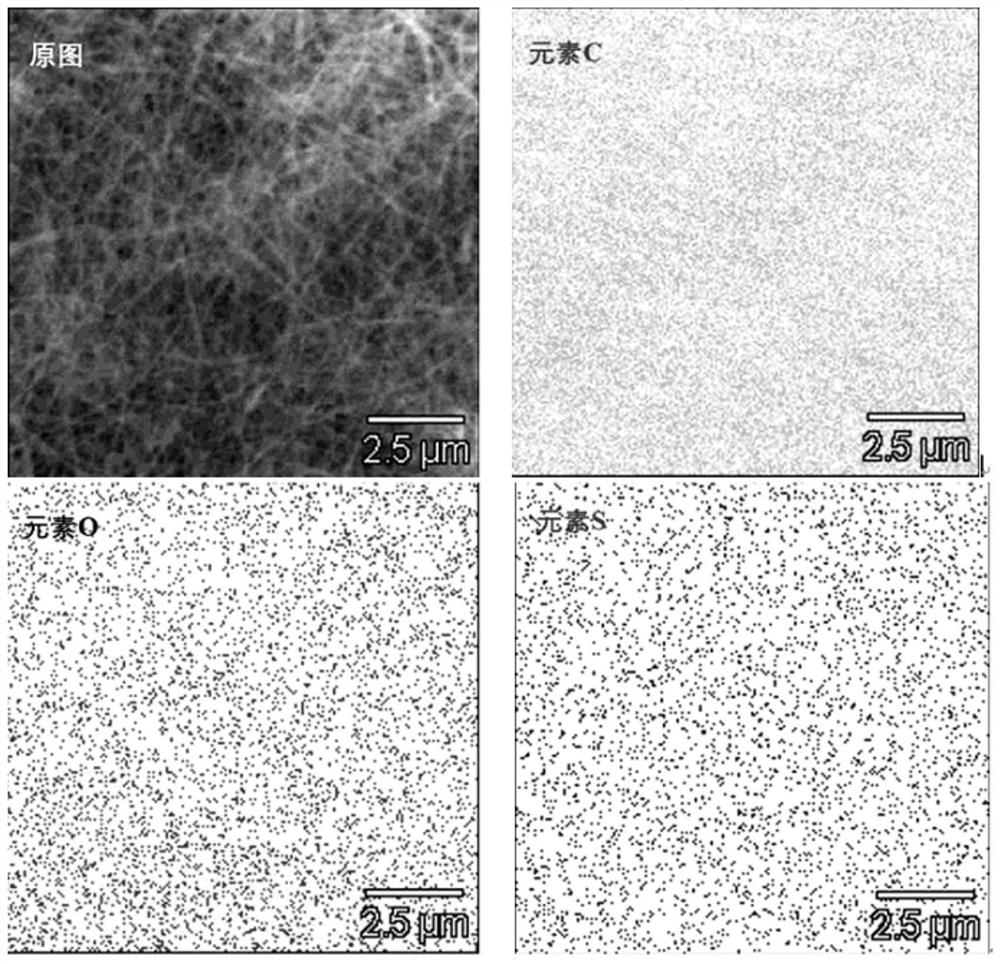

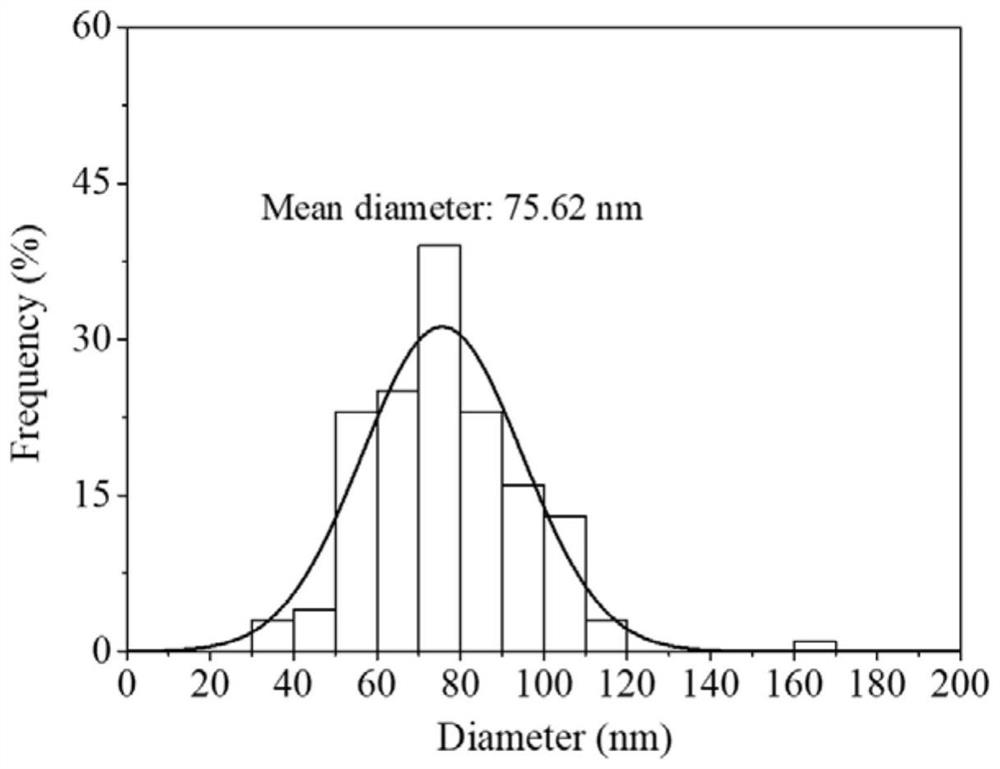

[0040] The preparation method of pullulan polysaccharide-animal esterase composite nanofiber comprises the steps:

[0041] (1) Extraction and purification of chicken liver esterase: crush the chicken liver and mix it with tromethamine-acetic acid buffer solution at a ratio of 30:100, add phenylmethylsulfonyl fluoride and 2,6-di-tert-butyl P-cresol was maintained at a concentration of 115 μmol / L and 45 μmol / L respectively. After the homogenate was centrifuged, 30 mL of the supernatant was taken, and ammonium sulfate was added to reach a saturation of 70%. The ratio of 1:10 was dialyzed in 0.1mol / L phosphate-buffered saline solution for 6 hours, and the supernatant was obtained after static centrifugation, which was the purified chicken liver esterase solution.

[0042] (2) Preparation of pullulan-chicken liver esterase electrospinning solution: according to the mass concentration of 0.15g / mL, the pullulan with a molecular weight of 150g / mol was dispersed in a phosphate buffered...

Embodiment 2

[0046] The preparation method of pullulan polysaccharide-porcine liver esterase composite nanofiber comprises the following steps:

[0047] (1) Extraction and purification of pig liver esterase: crush the pig liver and mix it with tromethamine-acetic acid buffer solution at a ratio of 20:200, add phenylmethylsulfonyl fluoride and 2,6-di-tert-butyl Keep the concentration of p-cresol at 100 μmol / L and 30 μmol / L respectively. After the homogenate is centrifuged, take 50 mL of the supernatant, add ammonium sulfate to 70% saturation, let it stand and centrifuge, take the precipitate and freeze-dry it, grind it into powder and use it as The ratio of 0.5:25 was dialyzed in 0.1mol / L phosphate buffered saline solution for 12 hours, and the supernatant was obtained after static centrifugation, which was the purified pig liver esterase solution.

[0048] (2) Preparation of pullulan-porcine liver esterase electrospinning solution: according to the mass concentration of 0.25g / mL, pullulan ...

Embodiment 3

[0052] The preparation method of pullulan polysaccharide-foie gras esterase composite nanofiber comprises the steps:

[0053] (1) Extraction and purification of foie gras esterase: crush the foie liver and mix it with tromethamine-acetic acid buffer solution at a ratio of 30:150, add phenylmethylsulfonyl fluoride and 2,6-di-tert-butyl P-cresol was maintained at a concentration of 130 μmol / L and 60 μmol / L respectively. After the homogenate was centrifuged, 40 mL of the supernatant was taken, and ammonium sulfate was added to reach a saturation of 70%. The ratio of 1.5:20 was dialyzed in 0.1mol / L phosphate-buffered saline solution for 8 hours, and the supernatant was obtained after static centrifugation, which was the purified foie gras esterase solution.

[0054] (2) Preparation of pullulan-foie gras esterase electrospinning solution: according to the mass concentration of 0.20g / mL, the pullulan with a molecular weight of 100g / mol was dispersed in a phosphate buffered saline so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com