Bioproduction of para-hydroxycinnamic acid

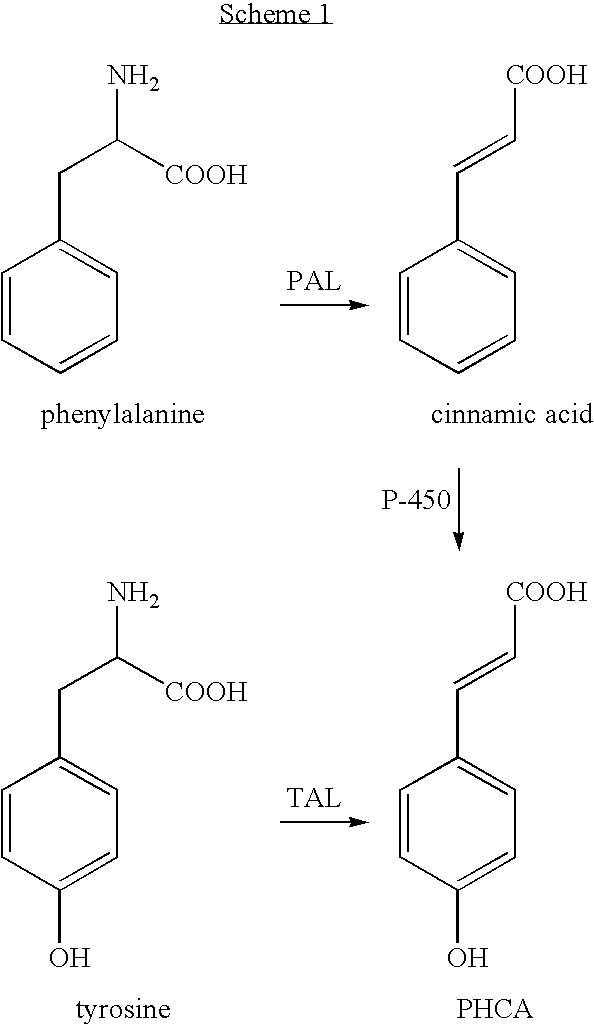

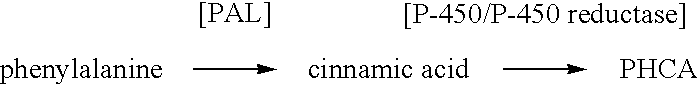

a technology of para-hydroxycinnamic acid and biosynthesis, which is applied in the field of biosynthesis of para-hydroxycinnamic acid, can solve the problems of limited carbon source concentration in a "batch" fermentation, cell death in stationary phase, and inability to expect the c-terminal and c-terminal portions of the protein molecule to change, etc., to achieve the effect of increasing the specificity of the substrate for tyrosine and increasing the activity of the substrate specifi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Microorganisms for Conversion of Cinnamic Acid to PHCA

[0178] Example 1 describes screening of various microorganisms for the presence of cinnamate hydroxylases and investigation of their ability to convert cinnamic acid to PHCA.

[0179] In order to discover microorganisms with cinnamate hydroxylase activity, over 150 different strains of bacteria and fungi were screened for their ability to convert cinnamic acid to PHCA. A two-stage fermentation protocol was used. Microorganisms were first grown in the medium for three days and then a 20% inoculum was used to start the second stage cultures. Following 24 h growth in stage two, cinnamic acid was added, samples were taken at intervals and analyzed by HPLC for the presence of PHCA.

[0180] Growth Media:

[0181] ATCC Medium #196--Yeast / Malt Medium

[0182] This medium contained (in grams per liter): malt extract, 6.0; maltose, 1.8; dextrose, 6.0; and yeast extract, 1.2. The pH was adjusted to 7.0.

[0183] ATCC Medium #5--Sporulation Broth

[0184] Th...

example 2

Screening of Microorganisms Containing Optimal TAL / PAL Activity Ratio

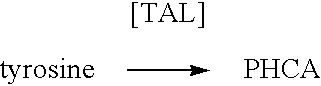

[0192] Example 2 describes the screening of various microorganisms for their PAL and TAL activities. This information was required to allow for selection of the most suitable microbe for further cloning, expression, purification and kinetic analysis of the PAL and PAL / TAL enzyme.

[0193] Medium for Growth and Induction of PAL in Streptomyces:

[0194] A two stage fermentation protocol was used for Streptomyces. Stage I medium contained, glucose (2%); soybean flour (1%); yeast extract (0.5%); meat extract (0.3%); calcium carbonate (0.3%); used 4% inoculum for stage II. Stage II medium contained, glucose (2%); yeast extract (2%); sodium chloride (0.5%); calcium carbonate (0.3%). The medium was distributed at 100 mL portions into 500 mL flasks. Cells transferred to this medium were incubated for 24 h at 25.degree. C. on a shaker.

[0195] Preparation of Cells of Rhodosporidium toruloides Following Growth in the Complex Medium...

example 3

Cloning and Expression of Rhodosporidium toruloides PAL in E. coli

[0204] Example 3 describes the cloning and expression of phenylalanine ammonia lyase (PAL) from Rhodosporidium toruloides in E. coli in order to produce sufficient quantities of PAL for purification.

[0205] RNA Purification:

[0206] The Rhodosporidium toruloides RNA was purified from exponential phase cells grown in the complex medium containing phenylalanine. The total RNA was isolated and the mRNA was purified using Qiagen total RNA and mRNA isolation kits, respectively, according to the manufacturers instructions.

[0207] Reverse Transcription:

[0208] The Rhodosporidium toruloides mRNA (3 .mu.L, 75 ng) was reversed transcribed according to Perkin Elmer (Norwich Conn.) GeneAmp kit instructions without diethylpyrocarbonate (DEPC) treated water. The PCR primers used (0.75 .mu.M) were the random hexamers supplied with the kit, the upstream primer (SEQ ID NO:1) 5'-ATAGTAGAATTCATGGCACCCTCGCTCGACTCGA-3-' containing a EcoRI rest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com