Clad steel plate manufacturing method using explosive welding and application thereof in linear motor

A technology of explosive welding and clad steel plates, applied in the direction of manufacturing tools, welding equipment, other manufacturing equipment/tools, etc., can solve the problems of ionization corrosion, reduced service life, low bonding rate of induction plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

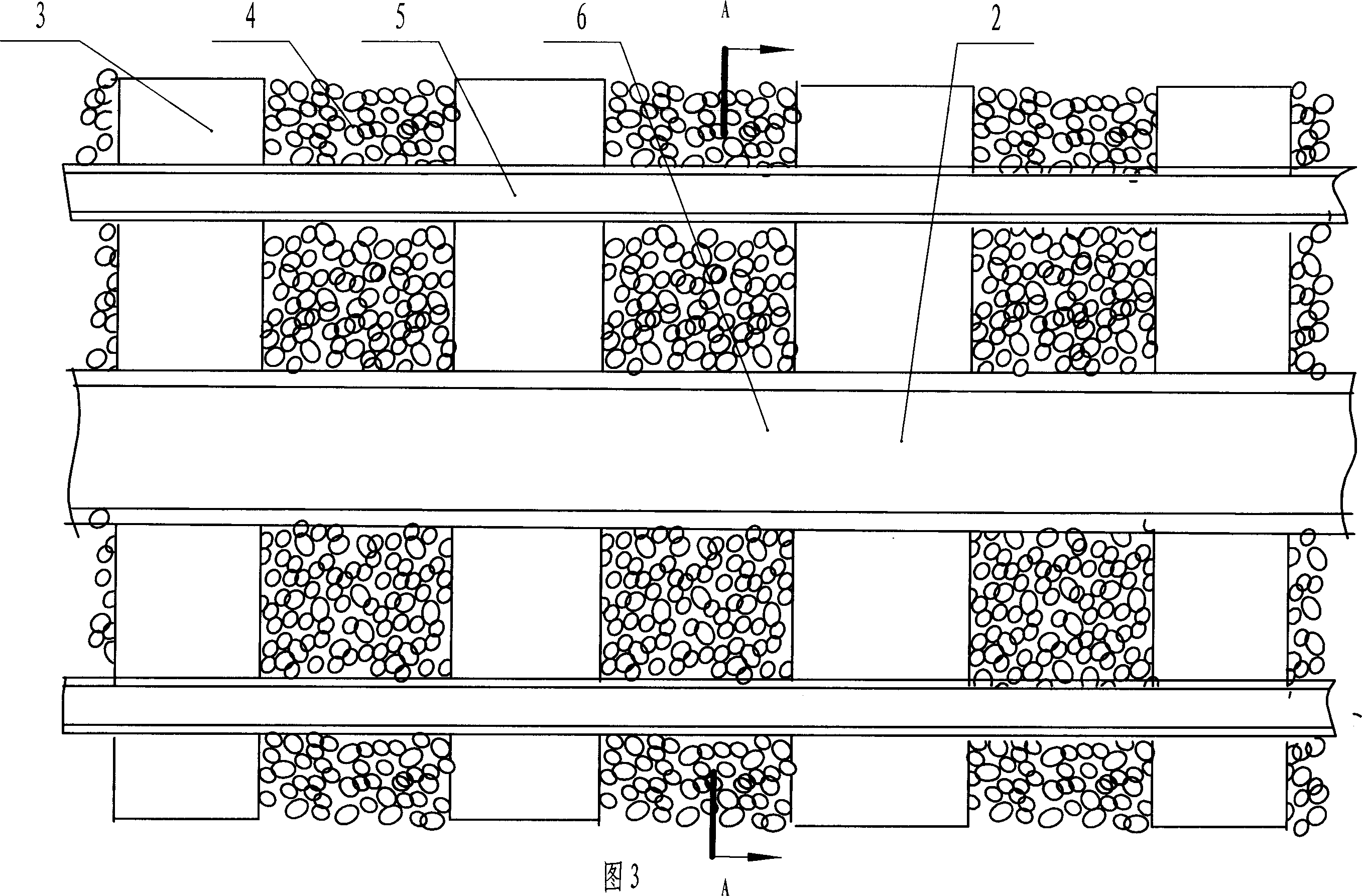

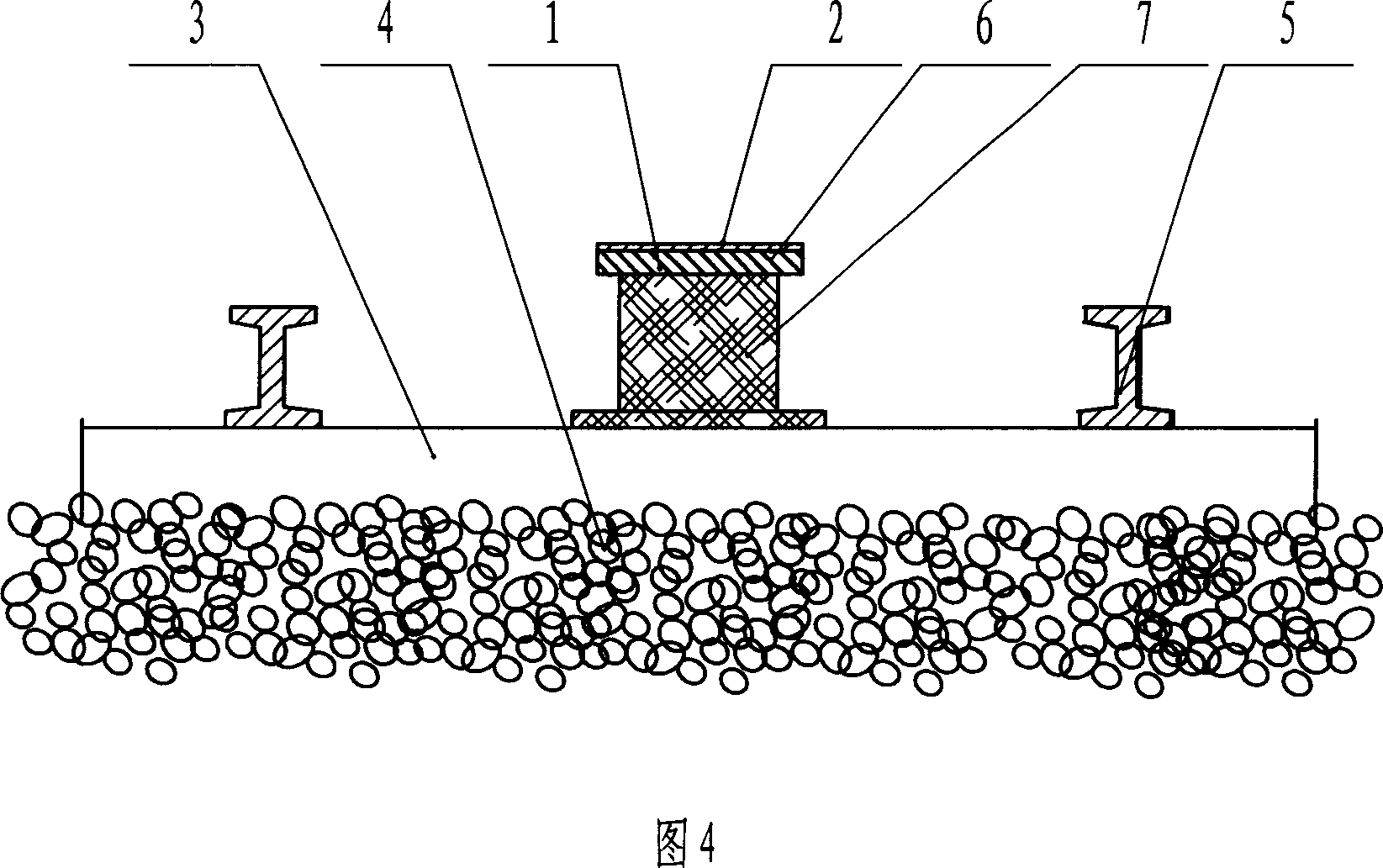

[0059] The explosive manufacturing method of this composite steel plate and its application in linear motors are described below in conjunction with the embodiments and accompanying drawings, but the explosive manufacturing method of this composite steel plate and its application in linear motors are limited to the following the described embodiment.

[0060] Embodiment 1 of manufacturing method of composite steel plate

[0061] The explosive welding manufacturing method embodiment of this clad steel plate is the following steps successively:

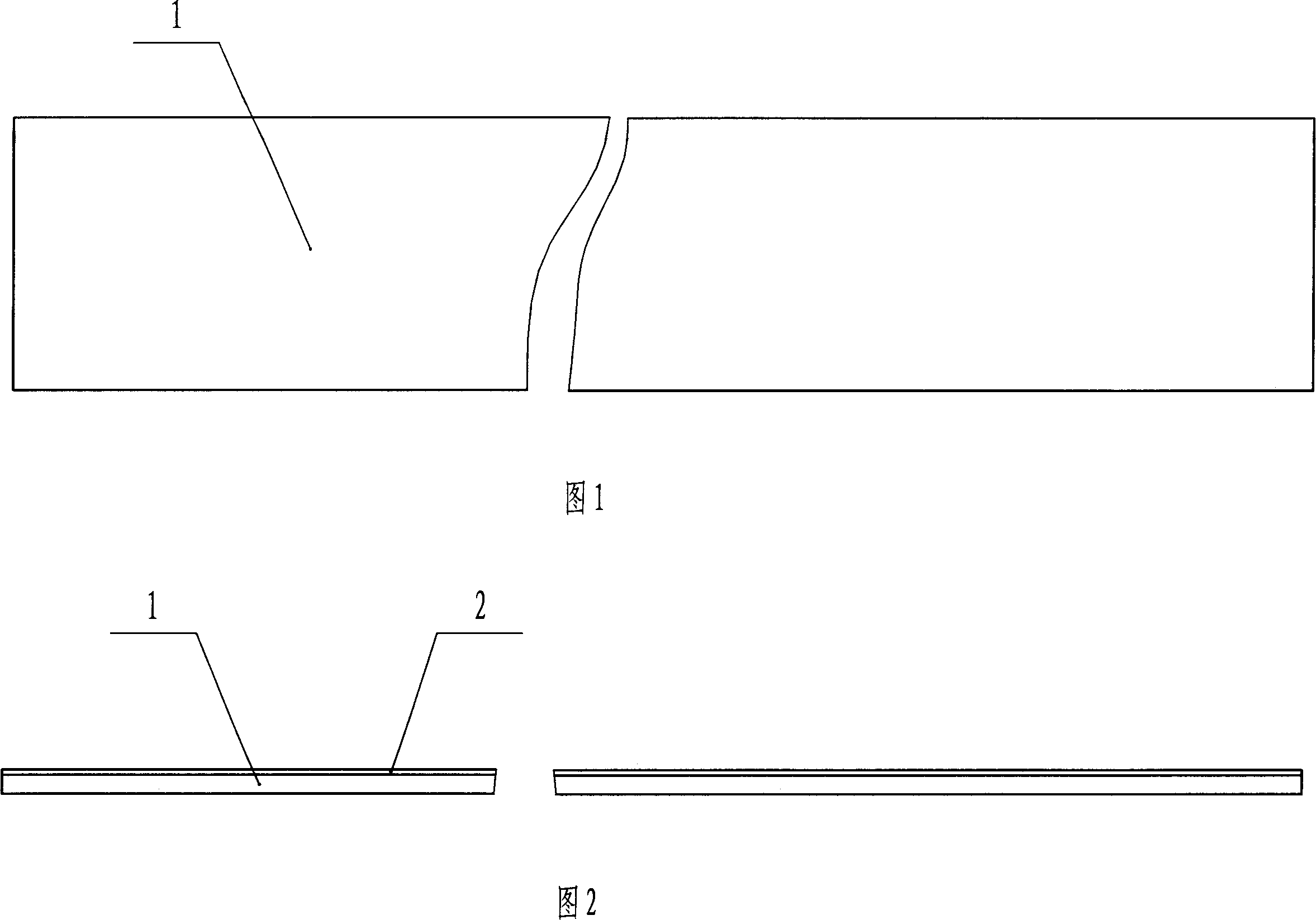

[0062] 1. Matching: inspect the aluminum plate and steel plate that need to be explosively combined, and if they meet the corresponding national standards and technical requirements, the aluminum plate and steel plate will be paired and matched according to the requirements of the final product. The overall dimensions are 5140mm in length, 810mm in width, 7mm in aluminum plate thickness, and 25mm in steel plate thickness;

[0063] 2. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com