Target material binding method

A target material and non-magnetic metal technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of non-reusable, solder waste, high cost of target material, etc., to increase electrical and thermal conductivity, Effects of reducing cost and controlling the thickness of welding layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

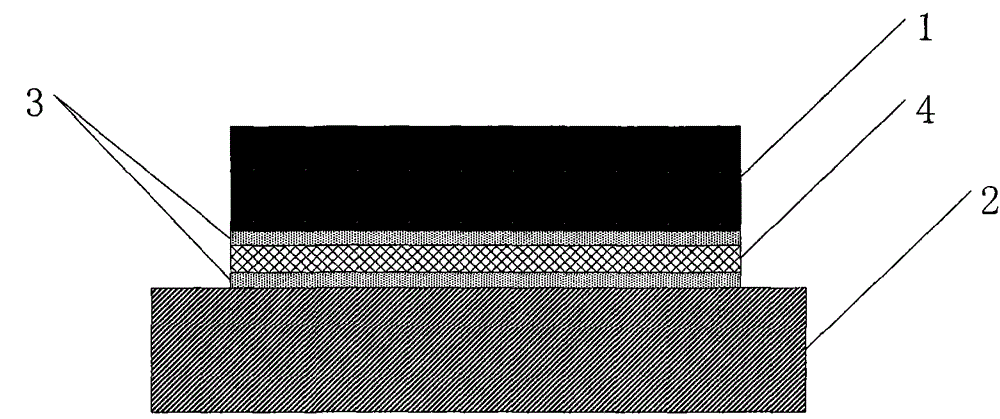

[0031] Follow the steps below to complete the figure 1 Binding of targets of the structures shown:

[0032] (1) Clean the welding surfaces of the target 1 and the back plate 2 with absolute ethanol;

[0033] (2) adding 60% by weight aluminum powder to the epoxy resin glue to make conductive glue 3, wherein the particle size of the aluminum powder is 1-120 μm;

[0034] (3) The conductive adhesive 3 is evenly coated on the welding surface of the target 1 and the back plate 2 and both sides of the copper mesh 4, wherein the mesh size of the copper mesh 4 is 20 mesh, and the copper mesh 4 The wire diameter of the net 4 is 0.15mm;

[0035] (4) The copper mesh 4 and the target material 1 are sequentially stacked on the welding surface of the back plate 2 and positioned, and the copper mesh 4 is located between the welding surface of the target material 1 and the back plate 2;

[0036] (5) Place a briquette on the target 1, and stand and solidify at normal temperature and pressure...

Embodiment 2

[0040] Follow the steps below to complete the figure 1 Binding of targets of the structures shown:

[0041] (1) Clean the welding surfaces of the target 1 and the back plate 2 with isopropanol;

[0042] (2) adding 60% by weight aluminum powder to the epoxy resin glue to make conductive glue 3, wherein the particle size of the aluminum powder is 1-120 μm;

[0043] (3) The conductive adhesive 3 is evenly coated on the welding surface of the target 1 and the back plate 2 and both sides of the copper mesh 4, wherein the mesh size of the copper mesh 4 is 22 mesh, and the copper mesh 4 The wire diameter of the net 4 is 0.15mm;

[0044] (4) The copper mesh 4 and the target material 1 are sequentially stacked on the welding surface of the back plate 2 and positioned, and the copper mesh 4 is located between the welding surface of the target material 1 and the back plate 2;

[0045] (5) Place a briquette on the target 1, and stand and solidify at normal temperature and pressure to o...

Embodiment 3

[0048] It differs from Example 1 in that: the mesh size of the copper mesh 4 is 24 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com