Low-temperature lead-free solder

A lead-free solder, low temperature technology, used in the field of soldering materials, electrical contact materials, and low temperature soldering in the electronic industry, can solve the performance of electrical contact materials (hardness, welding resistance, corrosion resistance, reliability, stability, etc.) The performance, accuracy and service life are not greatly improved, and the volume change of the solid-liquid phase is not large, the welding needs are met, and the contact is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 low temperature lead-free solder

[0037] Formula: Bi 40%, Sn 35%, Zn 0.2%, Al 0.15%, Cu 0.1%, P0.15% by mass percentage, and the rest is In.

[0038] Preparation:

[0039] (1) Add the weighed raw materials (40kg pure Bi, 35kg pure Sn, 200g pure Zn, 150g pure Al, 100g pure Cu, 150g pure P, 24.4kg pure In, 100kg in total) into the smelting furnace (200kg) according to the formula, Add 100g of ZnCl 2 Melt the covering agent, heat it to 650°C, and keep it warm for 30 minutes.

[0040] (2) After stirring the obtained melt for 30 minutes, remove the surface covering agent, and pour it into a mold to make a low-temperature solder ingot.

[0041] (3) On an extruder, extrude the ingot obtained in step (2) into strips, filaments or atomize to prepare spherical alloy solder powder.

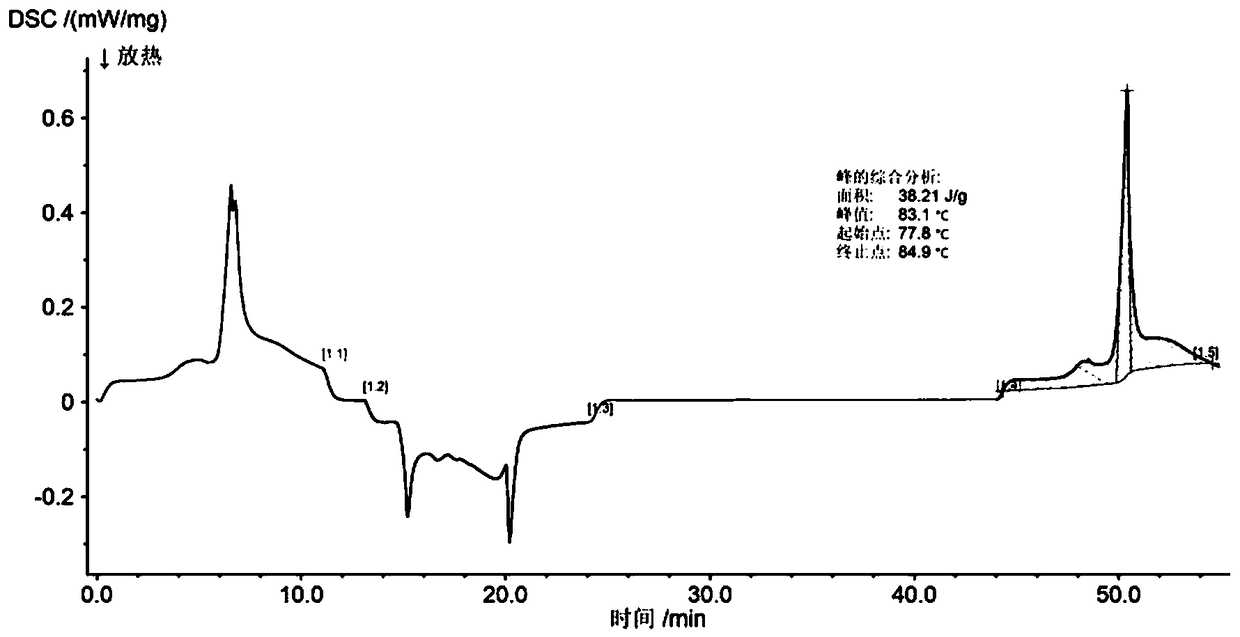

[0042] The temperature and time curve of the low-temperature lead-free solder in this embodiment is shown in figure 1 (DSC is Indicated Differential Scanning Calorimeter).

Embodiment 2

[0043] Embodiment 2 low temperature lead-free solder

[0044] Formula: Bi 40%, Sn 35% by mass percentage, and the rest is In.

[0045] Preparation method: with reference to Example 1.

Embodiment 3

[0046] Embodiment 3 low temperature lead-free solder

[0047] Formula: Bi 40%, Sn 34%, Zn 0.5%, Al 0.1%, Ag 0.1%, Cu0.1% by mass percentage, and the rest is In.

[0048] Preparation method: with reference to Example 1.

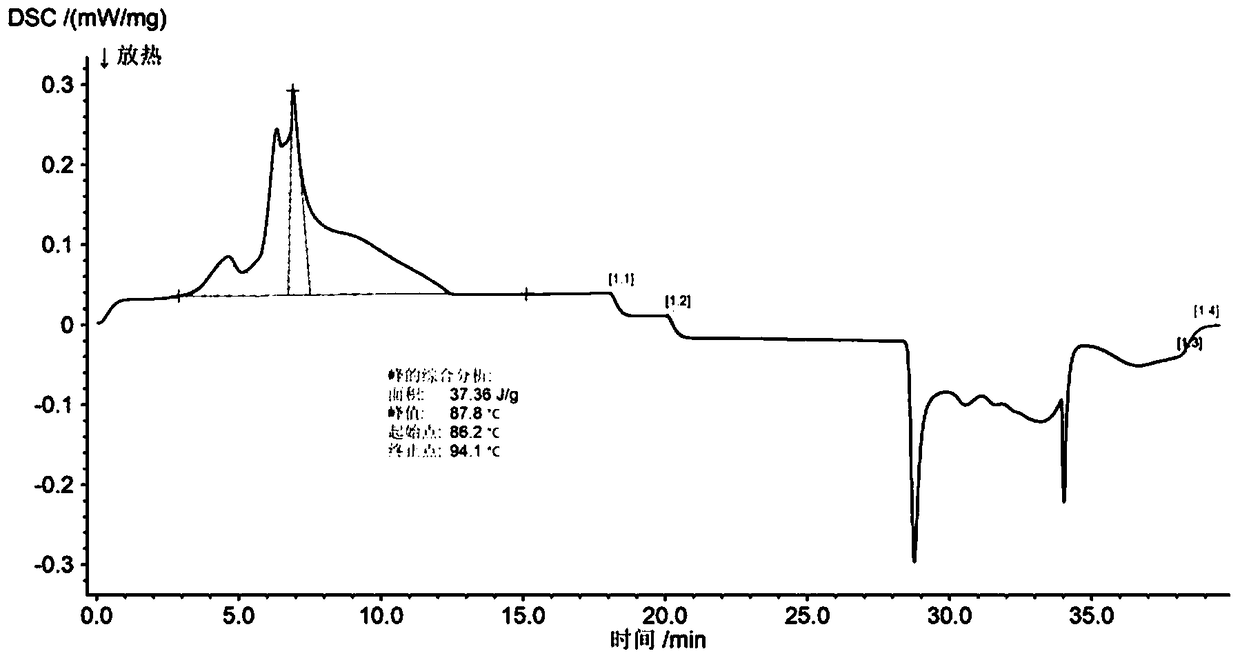

[0049] The temperature and time curve of the low-temperature lead-free solder in this embodiment is shown in figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

| solidus temperature | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com