Copper nanofluid solar cooling liquid and preparation method thereof

A copper nano, solar energy technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of reducing the thermal conductivity of copper nano fluid cooling liquid, unstable dispersion of copper nano powder, easy to agglomerate, etc., to avoid oxidation problems. , the adsorption effect is stable, the effect of reducing the relative density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

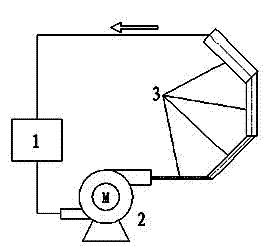

Image

Examples

Embodiment 1

[0025] A kind of copper nanofluid solar cooling liquid, it is made up of following components by weight: 55 parts of deionized water, 15 parts of ethylene glycol, 24 parts of propylene glycol, and average particle diameter is 3.5 parts of nano copper powder of 50nm, ethylene 0.6 parts of pyridine, 0.006 parts of azobisisobutyronitrile, 0.35 parts of polyvinylpyrrolidone, 0.2 parts of 1,3-dimethyl-2-imidazolinone, 0.34 parts of sodium tripolyphosphate, 0.36 parts of potassium dihydrogen phosphate, 0.24 parts of sodium phosphite, 0.31 parts of sodium hypophosphite, and 0.1 part of benzotriazole.

[0026] Its preparation method is: sodium tripolyphosphate, potassium dihydrogen phosphate, sodium phosphite and sodium hypophosphite are stirred and dissolved in deionized water with a tetrafluoroelectric electric stirrer to obtain a phosphate aqueous solution. The pH value of the final nanofluid is stabilized at about 10.2, which is the optimal pH region where the nanofluid can exist ...

Embodiment 2

[0032] A kind of copper nanofluid solar cooling liquid, it is made up of following components by weight: 55 parts of deionized water, 15 parts of ethylene glycol, 24 parts of propylene glycol, and average particle diameter is 3.5 parts of nano copper powder of 50nm, ethylene 0.6 parts of pyridine, 0.006 parts of azobisisobutyronitrile, 0.35 parts of polyvinylpyrrolidone, 0.2 parts of 1,3-dimethyl-2-imidazolinone, 0.34 parts of sodium tripolyphosphate, 0.36 parts of potassium dihydrogen phosphate, 0.24 parts of sodium phosphite, 0.31 parts of sodium hypophosphite, and 0.1 part of benzotriazole.

[0033] The steps of the preparation method in this example are the same as those in Example 1. The difference is that the copper nano-copper powder is added to the alcohol solution, and the rotation speed is 20 kr / min to disperse for 4 minutes, and then vinylpyridine and azobisisobutyronitrile are added. Continue to disperse at a rotational speed of 20kr / min for 4min. In the stage of v...

Embodiment 3

[0038] A kind of copper nanofluid solar cooling liquid, it is made up of following components by weight: 50 parts of deionized water, 22 parts of ethylene glycol, 22 parts of propylene glycol, and average particle diameter is 3.5 parts of nano copper powder of 20nm, ethylene 0.8 parts of pyridine, 0.007 parts of azobisisobutyronitrile, 0.25 parts of polyvinylpyrrolidone, 0.25 parts of 1,3-dimethyl-2-imidazolinone, 0.2 parts of sodium tripolyphosphate, 0.34 parts of potassium dihydrogen phosphate, 0.254 parts of sodium phosphite, 0.25 parts of sodium hypophosphite, 0.2 parts of benzotriazole.

[0039] The steps of the preparation method in this embodiment are the same as those in Embodiment 2 and will not be repeated. The test results show that,

[0040] (1) In this case, the polyvinylpyridine-coated copper nanofluid had only insignificant turbidity after standing for 1500 hours without the treatment of the folded and reduced-diameter tube flowing through it;

[0041] (2) The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com