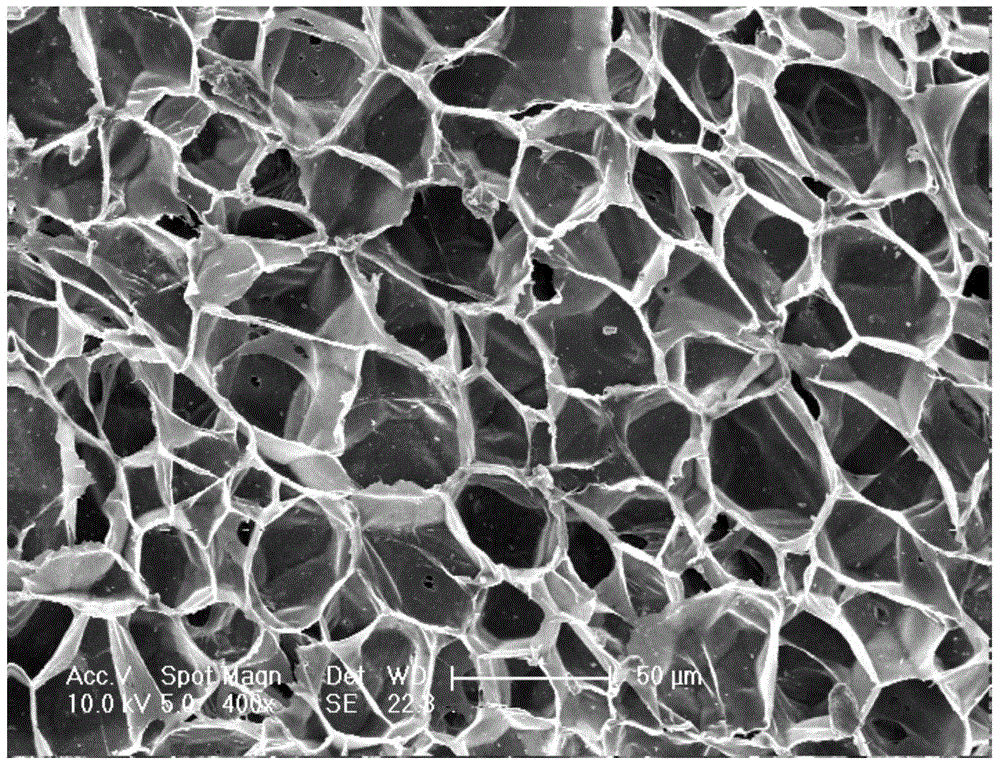

Carbon dioxide-epoxypropane copolymer foam plastic and preparation method thereof

A technology of carbon dioxide and propylene oxide, which is applied in the field of foam plastics, can solve the problems of limited application and incomplete biodegradation of foam plastics, and achieve the effects of good dimensional stability, good mechanical properties, and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a kind of preparation method of carbon dioxide-propylene oxide copolymer foamed plastics, comprises the following steps:

[0040] 1), granulate after mixing carbon dioxide-propylene oxide copolymer and toughening agent, obtain plastic granule, and described toughening agent comprises polyadipate-terephthalate-butylene glycol ester, ethylene-octene copolymer One or more of ethylene-acrylic acid copolymer, ethylene-methyl acrylate copolymer and thermoplastic polyurethane elastomer rubber;

[0041] 2), the plastic particles are placed in a carbon dioxide environment of 3MPa~8MPa, and the plastic particles absorb carbon dioxide and perform pressure relief treatment to obtain carbon dioxide-propylene oxide copolymer foam plastics; the speed of the pressure relief treatment is 5MPa / s~20MPa / s.

[0042] The present invention adopts carbon dioxide-propylene oxide copolymer and toughening agent as raw material, prepares carbon dioxide-propylene oxide copo...

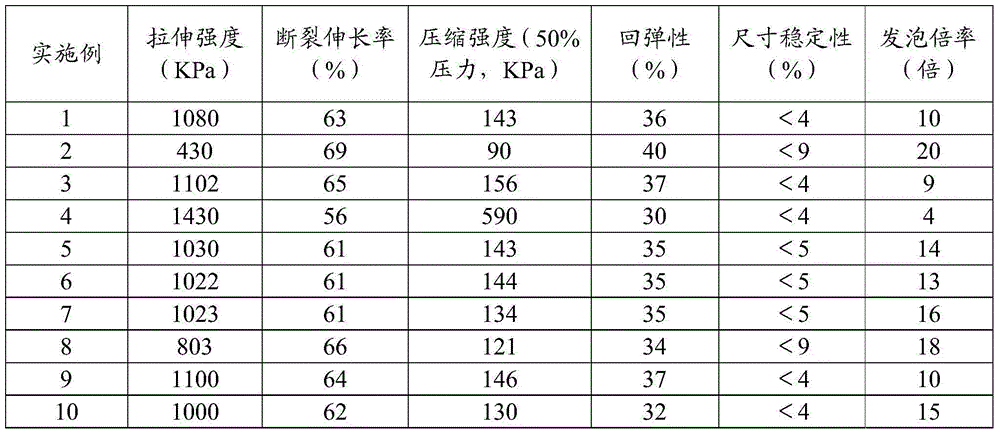

Embodiment 1

[0058] The number-average molecular weight of 100g is the carbon dioxide-propylene oxide copolymer of 100000g / mol and the polyadipate-terephthalate-butylene glycol ester of 150g in the mixing machine and mixes, then the mixture that obtains is added twin-screw Carry out granulation in a granulator to obtain plastic granules; in the granulation process, the temperature of the first zone of the twin-screw granulator is 120°C, the temperature of the second zone is 165°C, the temperature of the third zone is 170°C, and the temperature of the fourth zone is 170°C. The temperature is 175°C, the temperature of the fifth zone is 175°C, the temperature of the sixth zone is 175°C, the temperature of the seventh zone is 170°C, and the temperature of the die head is 150°C.

[0059] After obtaining the plastic granules, place the plastic granules in an autoclave, fill the autoclave with 5 MPa of carbon dioxide at 25° C., heat the autoclave to 130° C., and hold the pressure at a constant tem...

Embodiment 2

[0063] The number-average molecular weight of 100g is the carbon dioxide-propylene oxide copolymer of 100000g / mol and the polyadipate-terephthalate-butylene glycol ester of 50g are mixed homogeneously in mixer, then the mixture that obtains is added twin-screw Carry out granulation in a granulator to obtain plastic granules; in the granulation process, the temperature of the first zone of the twin-screw granulator is 120°C, the temperature of the second zone is 165°C, the temperature of the third zone is 170°C, and the temperature of the fourth zone is 170°C. The temperature is 175°C, the temperature of the fifth zone is 175°C, the temperature of the sixth zone is 175°C, the temperature of the seventh zone is 170°C, and the temperature of the die head is 150°C.

[0064] After obtaining the plastic granules, place the plastic granules in an autoclave, fill the autoclave with 5 MPa of carbon dioxide at 25° C., heat the autoclave to 140° C., and keep the pressure at a constant tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com