Self-absorption air type cyclone foaming device for dust removal of coal mine

A foaming device, air-type technology, applied in safety devices, dust-proofing, mining equipment and other directions, can solve the problems of on-site operation, adjustment difficulties, large energy loss of pressure water, inability to effectively form liquid film, etc., to shorten installation and commissioning. The effect of low time and labor intensity, reducing operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

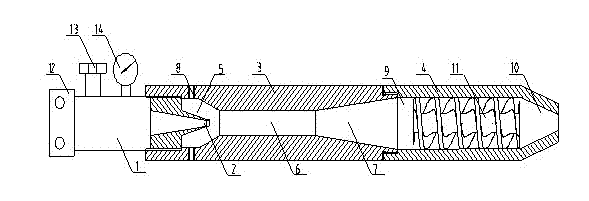

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

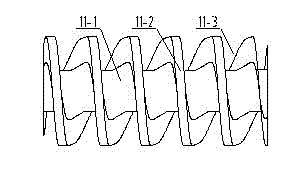

[0015] Such as figure 1 As shown, the self-suction air-type swirl foaming device for dust reduction in coal mines of the present invention is composed of a foaming liquid supply pipe 1, a jet nozzle 2, an air suction mixing cylinder 3 and a foaming cylinder 4. The foaming liquid supply pipe 1 of the joint 12, the pressure regulating valve 13 and the pressure gauge 14 is connected with the conical jet nozzle 2, and the air suction chamber 5, the gas-liquid mixing chamber 6, Diffused into a bubble chamber 7, the jet nozzle 2 is threaded into the suction chamber 5, two circular suction holes 8 are arranged on the wall of the suction chamber 5, and the diameter of the cylindrical gas-liquid mixing chamber 4 is the outlet of the jet nozzle 2 4~6 times of the diameter, the length of the gas-liquid mixing chamber 4 is 15~20 times of its own diameter, the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com