Water-based epoxy multifunctional steel structure paint and preparation method thereof

A steel structure coating, water-based epoxy technology, applied in the direction of epoxy resin coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve problems such as failure, poor water resistance, and decreased fire resistance of coatings, so as to increase foaming rate and enhance water resistance , Improve the effect of fire resistance limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

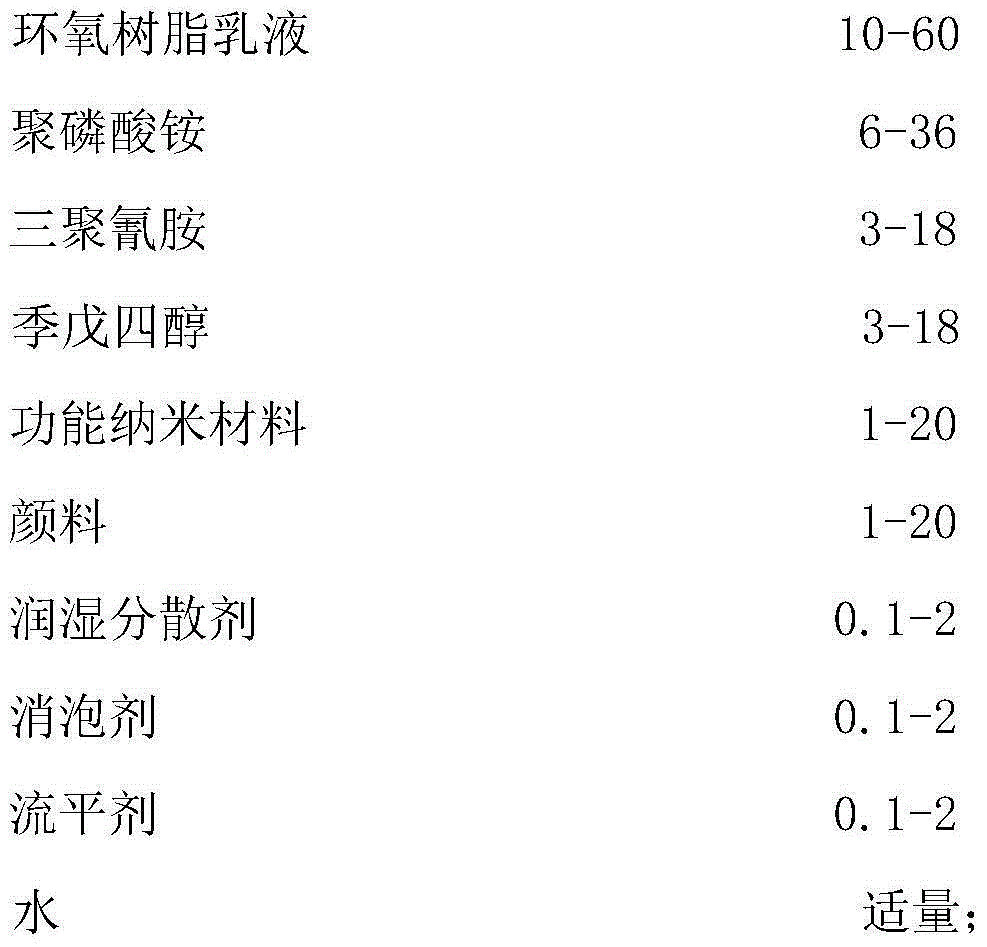

Method used

Image

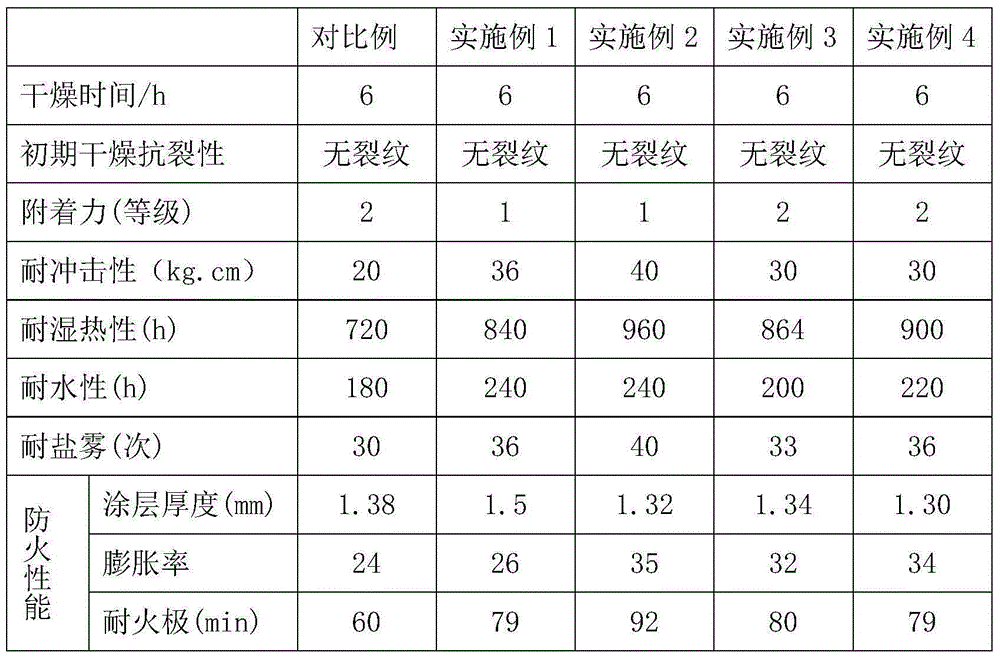

Examples

Embodiment 1

[0027] (1) Weigh 26.66g of ammonium polyphosphate, 13.33g of pentaerythritol, 13.33g of melamine, 11.997g of titanium dioxide, and 1.333g of nano zirconium phosphate, and pre-mix them.

[0028] (2) In the dispersing kettle, add 40ml of water, 0.5ml of BNK-NSF0678, 0.5ml of DP60-6200 and 0.3ml of BNK-G408 in turn, stir at 300r / min, and mix the materials in (1) gradually join in. With the continuous addition of materials, gradually increase the stirring speed. After all the materials are added, stir at 1300r / min for 30 minutes.

[0029] (3) Reduce the stirring speed to 500r / min, add epoxy resin emulsion and 0.2ml BNK-G408, then increase the stirring speed to 1200r / min, stir and disperse for 30 minutes, and obtain component A of water-based epoxy multifunctional steel structure coating .

[0030] (4) Add the curing agent of component B (33.3g) into component A, stir at 500r / min, and then sieve to obtain a water-based epoxy multifunctional steel structure coating.

[0031] (5)...

Embodiment 2

[0033] (1) Weigh 26.66g of ammonium polyphosphate, 13.33g of pentaerythritol, 13.33g of melamine, 10.664g of titanium dioxide, and 2.666g of nano zirconium phosphate, and pre-mix them.

[0034] (2) In the dispersing kettle, add 40ml of water, 0.5ml of BNK-NSF0678, 0.5ml of DP60-6200 and 0.3ml of BNK-G408 in turn, stir at 300r / min, and mix the materials in (1) gradually join in. With the continuous addition of materials, gradually increase the stirring speed. After all the materials are added, stir at 1300r / min for 30 minutes.

[0035] (3) Reduce the stirring speed to 500r / min, add epoxy resin emulsion and 0.2ml BNK-G408, then increase the stirring speed to 1200r / min, stir and disperse for 30 minutes, and obtain component A of water-based epoxy multifunctional steel structure coating .

[0036] (4) Add the curing agent of component B (33.3g) into component A, stir at 500r / min, and then sieve to obtain a water-based epoxy multifunctional steel structure coating.

[0037] (5)...

Embodiment 3

[0039] (1) Weigh 26.66g of ammonium polyphosphate, 13.33g of pentaerythritol, 13.33g of melamine, 9.331g of titanium dioxide, and 3.999g of nano zirconium phosphate, and pre-mix them.

[0040] (2) In the dispersing kettle, add 40ml of water, 0.5ml of BNK-NSF0678, 0.5ml of DP60-6200 and 0.3ml of BNK-G408 in turn, stir at 300r / min, and mix the materials in (1) gradually join in. With the continuous addition of materials, gradually increase the stirring speed. After all the materials are added, stir at 1300r / min for 30 minutes.

[0041] (3) Reduce the stirring speed to 500r / min, add epoxy resin emulsion and 0.2ml BNK-G408, then increase the stirring speed to 1200r / min, stir and disperse for 30 minutes, and obtain component A of water-based epoxy multifunctional steel structure coating .

[0042] (4) Add the curing agent of component B (33.3g) into component A, stir at 500r / min, and then sieve to obtain a water-based epoxy multifunctional steel structure coating.

[0043] (5) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com