Thermoplasticity environmentally-friendly stone paper and preparation method

An environmentally friendly stone paper, thermoplastic technology, applied in the direction of paper, papermaking, textiles and papermaking, etc., can solve problems such as the inability to meet the development of stone paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

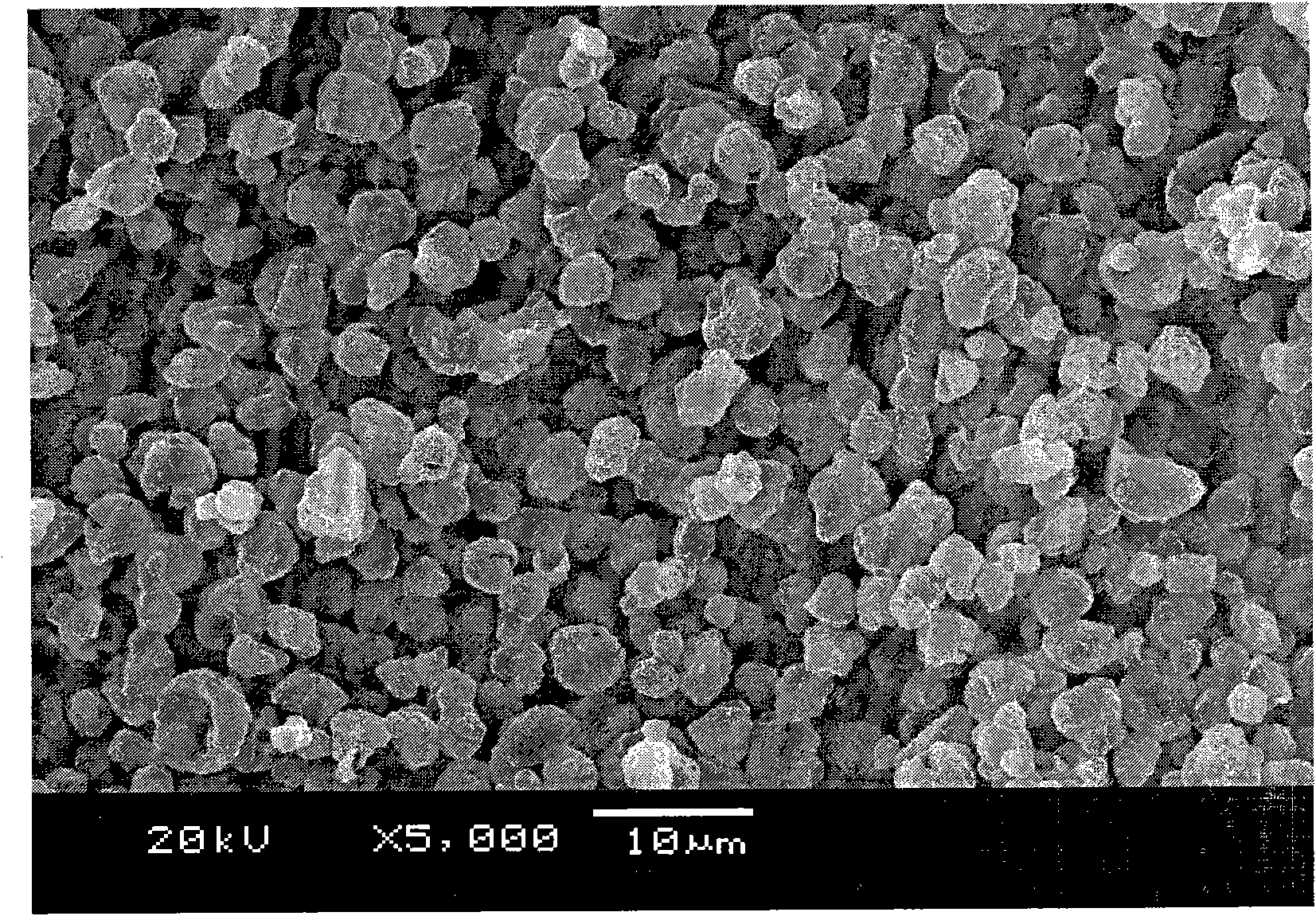

[0034] 1) Heat up the L-100 / 200 mixing mixer to a constant temperature of 80°C, add 85kg of bentonite with a particle size of 1250 mesh and 3kg of stearic acid into the mixer, and stir for 10 minutes at a stirring speed of 400rpm;

[0035] 2) Increase the stirring speed to 1500rpm, slowly and evenly add 2kg of styrene, and stir at a high speed for 10 minutes, so that the styrene monomer is evenly coated on the surface of the bentonite particles;

[0036] 3) Send the coated bentonite to a cold mixer, add 5kg of polypropylene, stir and cool to below 50°C, then add 0.05kg of azobisisobutyronitrile and mix well.

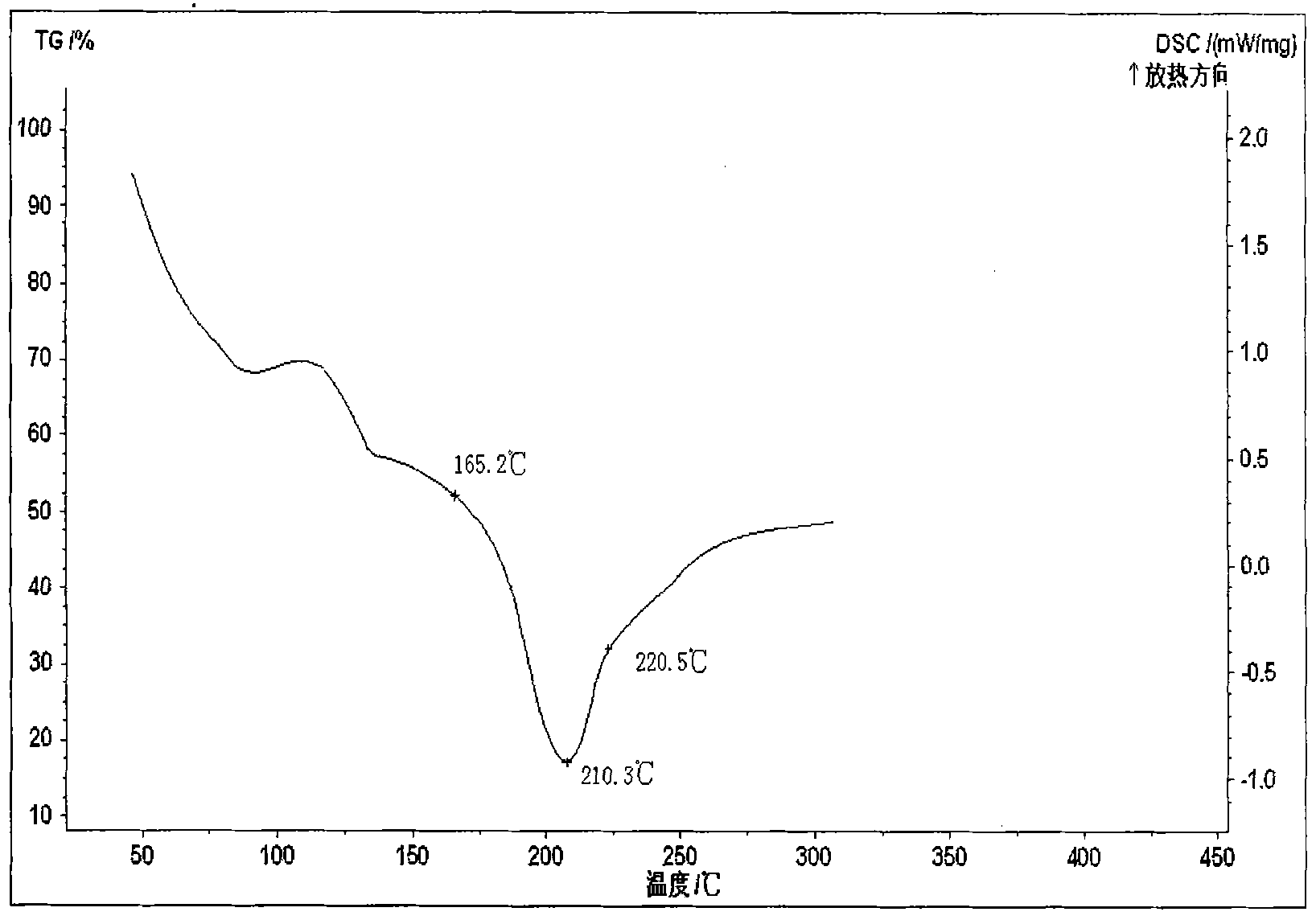

[0037] 4) Send the above mixture into a co-rotating twin-screw extruder (screw length-to-diameter ratio greater than 52:1) for extrusion and granulation, the screw speed of the host machine is 200rpm, and the temperature of each zone is controlled at: 1 zone 80°C; 2 zone 100°C ; 165°C in the third zone; 195°C in the fourth zone; 170°C in the fifth zone, a thermoplastic p...

Embodiment 2

[0043] 1) Heat up the W-100 / 200 mixing mixer to a constant temperature of 120°C, add 70kg of light calcium carbonate with a particle size of 2000 mesh, 10kg of titanium dioxide with a particle size of 2500 mesh, 1kg of isotridecyl phosphate, and 3kg of aluminate into the mixer. Stirring and reacting for 5 minutes at a stirring speed of 900rpm;

[0044] 2) Increase the stirring speed to 1200rpm, slowly and evenly add 2.5kg methyl methacrylate, and stir at a high speed for 10 minutes, so that the methyl methacrylate monomer is evenly coated on the surface of the bentonite particles;

[0045] 3) Send the coated powder to a cold mixer, add 8kg of high-density polyethylene and 2kg of ethylene-vinyl acetate copolymer, continue to stir and cool to below 50°C, add 0.01kg of dicumyl peroxide and mix well.

[0046] 4) Send the above mixture into a co-rotating twin-screw extruder for extrusion and granulation. The length-to-diameter ratio of the screw is greater than 52:1, the screw spee...

Embodiment 3

[0052] 1) Heat up the L-300 / 600 mixing mixer to a constant temperature of 100°C, mix 25kg wollastonite powder with a particle size of 1250 mesh, 60kg calcite powder with a particle size of 1250 mesh, 0.5kg titanate, 3kg zirconate, 0.5kg amino poly Alcohol ester (JL-G02 amino polyol ester, produced by Nanjing Jinlaiwang Co., Ltd.) was added to the mixer, and stirred and reacted for 8 minutes at a stirring speed of 500rpm;

[0053] 2) Increase the stirring speed to 1500rpm, slowly and evenly add 2.5kg of methyl acrylate, and stir at high speed for 10 minutes, so that the monomer is evenly coated on the surface of the particles;

[0054] 3) Send the coated particles to a cold mixer, add 4kg of polycaprolactone and 4kg of ethylene-acrylic acid copolymer, continue to stir and cool to below 50°C, add 0.01kg of dibenzoyl peroxide and mix well.

[0055] 4) Send the above mixture into a co-rotating twin-screw extruder for extrusion and granulation. The length-to-diameter ratio of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com