Multi-function composite optical membrane capable of replacing diffusion plate and manufacturing method thereof, and display screen

An optical film and multi-functional technology, applied in optics, optical components, and other household appliances, can solve problems such as increased manufacturing costs, uneven brightness, and light spots, and achieve the effects of saving costs and improving yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

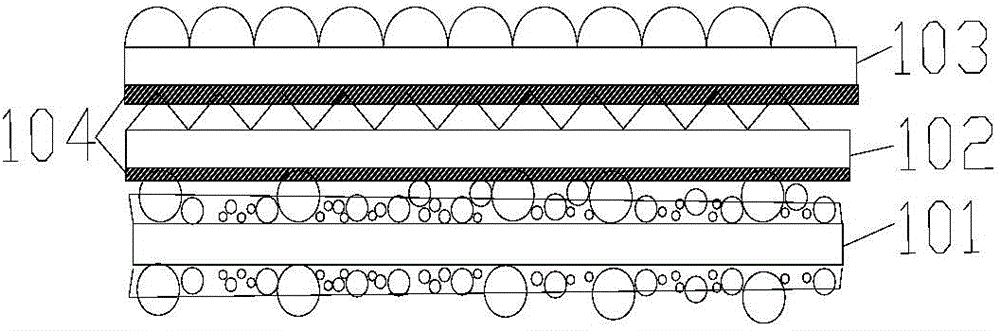

[0043] The structure of the composite optical film is:

[0044] Lower layer: diffusion film of double-sided light diffusion layer, middle layer: prism film, upper layer: microlens film (abbreviated as microlens film).

[0045] The diffusion film of the double-sided light-diffusing layer is a PET base material with a thickness of 250 μm, and the light-diffusing layer includes 100 parts by weight of polyurethane resin, 100 parts by weight of PMMA particles with a particle diameter of 15 μm, and 10 parts by weight of PMMA particles with a particle size of 15 μm. 1 μm TiO 2 Particles and double-sided light-diffusing layers have the same composition. The prism strips of the prism film are regular straight lines with a height of 50 μm and an angle of 90°. The material of the prism layer is acrylic resin, and the base material is PET with a thickness of 250 μm. The structure of the microlens film is a hemispherical structure, the radius of the hemispherical structure is 60 μm, the ...

Embodiment 2

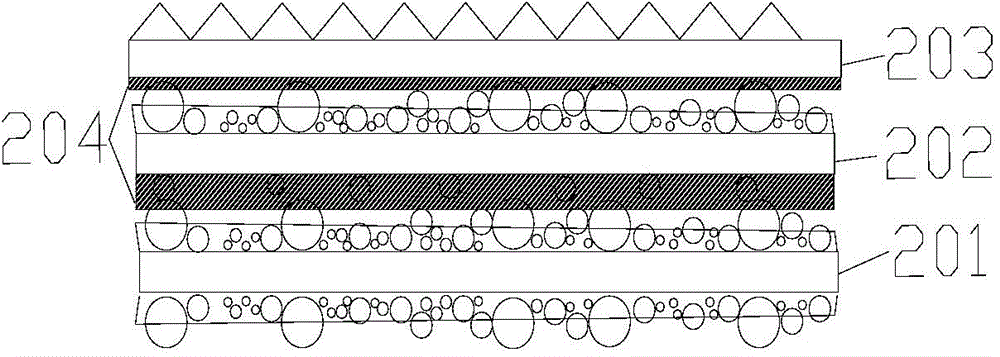

[0047] The structure of the composite optical film is:

[0048] Lower layer: diffusion film with double-sided light diffusion layer, middle layer: diffusion film with one light diffusion layer and one anti-adhesion layer, upper layer: prism film

[0049] The diffusion film of the lower double-sided light diffusion layer is a PC substrate with a thickness of 250 μm, the lower surface light diffusion layer includes 100 parts by weight of polyurethane resin, 150 parts by weight of polystyrene particles with a particle size of 25 μm, and the upper surface light diffusion The layer includes 100 parts by weight of polyurethane resin and 10 parts by weight of polystyrene particles with a particle diameter of 25 μm. The diffusion layer of the middle layer is a PC substrate with a thickness of 250 μm, and the light diffusion layer on the upper surface includes 100 parts by weight of polyurethane resin, 20 parts by weight of polystyrene particles with a particle size of 15 μm, and 80 pa...

Embodiment 3

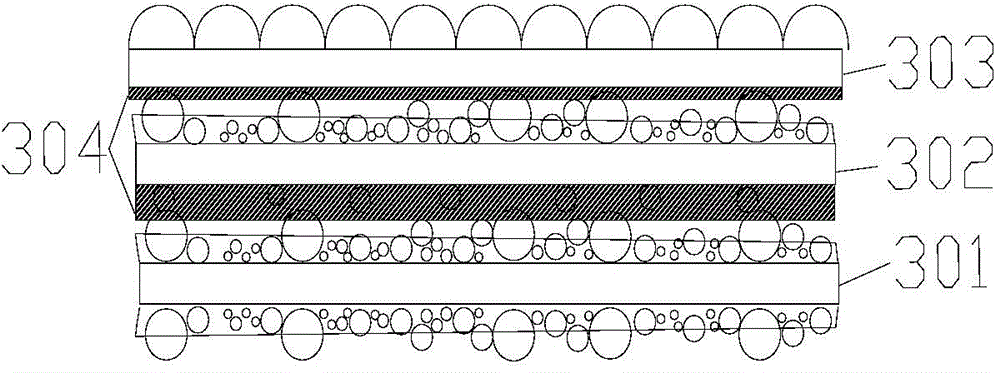

[0051] The structure of the composite optical film is:

[0052] Lower layer: Diffusion film of double-sided light diffusion layer, Middle layer: Two prism films perpendicular to the direction of the prism strips, Upper layer: Diffusion film of one light diffusion layer and one anti-adhesion layer.

[0053] The diffusion film of the lower double-sided light-diffusing layer is a PET base material with a thickness of 150 μm. The light-diffusing layer includes 100 parts by weight of polyurethane resin, 90 parts by weight of PMMA particles with a particle diameter of 25 μm, and 3 parts by weight of PMMA particles. TiO with a diameter of 1 μm 2 Particles and double-sided light-diffusing layers have the same composition. The prism film in the middle layer is two identical prism films up and down. When the two prism films are placed, the direction of the prism strips is vertical. The prism film is made of a PC base material with a thickness of 200 μm. °, the material of the prism la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Edges and corners | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com