Method for preparing one-dimensional photonic crystal film on fabric surface to realize structural color

A technology of dimensional photonic crystal and structural color, applied in the fields of plant fiber, fiber processing, textile and papermaking, etc., can solve the problems of polluting the environment and endangering human health, and achieve the effect of simple production equipment, low price and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 40 grams of tetrabutyl titanate in 13 grams of acetic acid, add the acetic acid solution of tetrabutyl titanate dropwise to the solution containing 0.13 g of hydrochloric acid and 149 grams of water under mechanical stirring at 300 rpm, and mix them uniform, stirred at room temperature for 2 hours, and aged for 24 hours to obtain a transparent titanium-containing sol.

[0030] Dissolve 10 g of tetraethyl orthosilicate in a mixed solution containing 26 g of ethanol and 24 g of water under mechanical stirring, adjust the pH to 3.1 with hydrochloric acid, and mechanically stir at 300 rpm for 2 hours to form a stable and uniform silica sol.

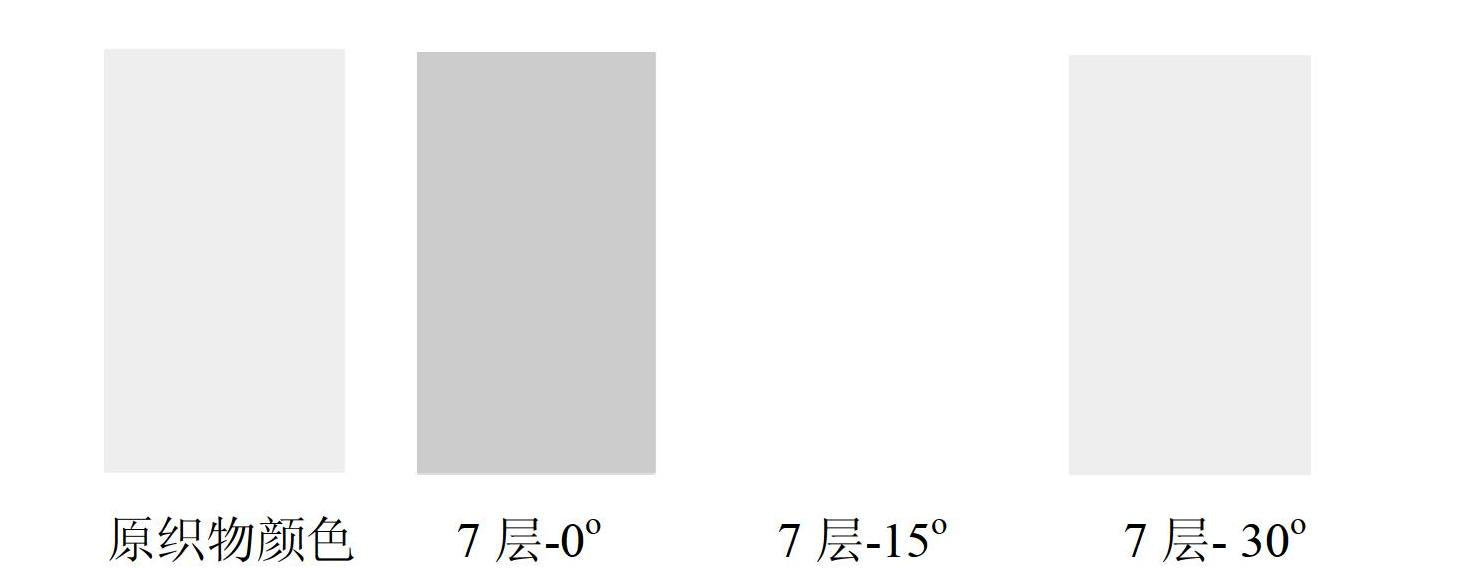

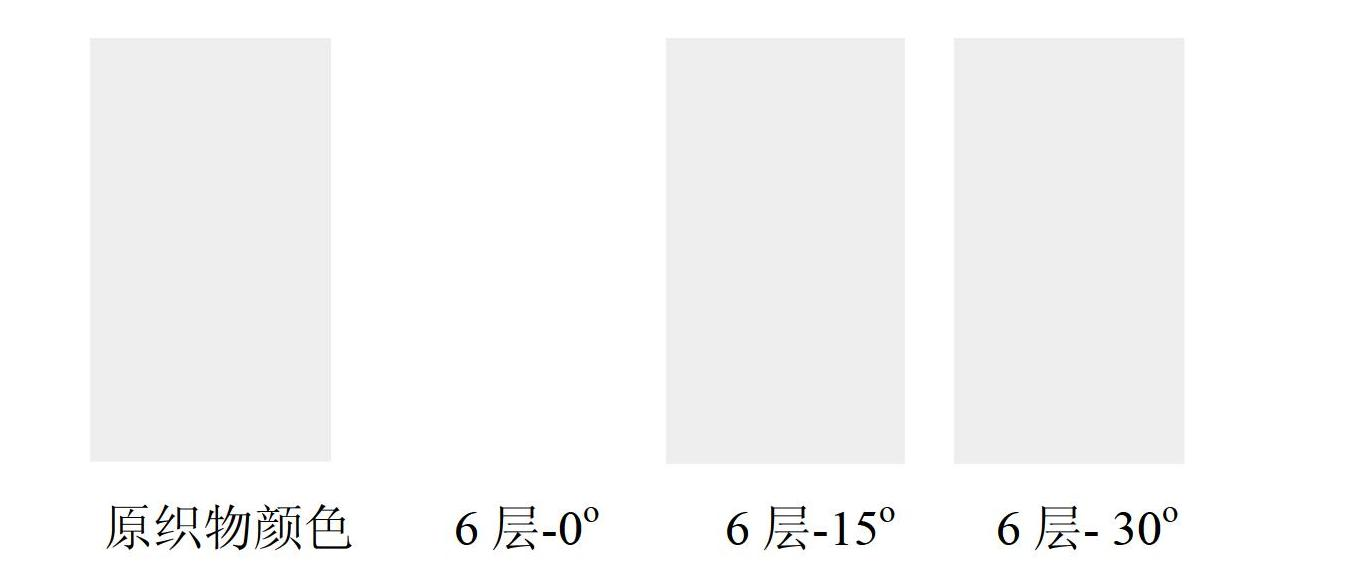

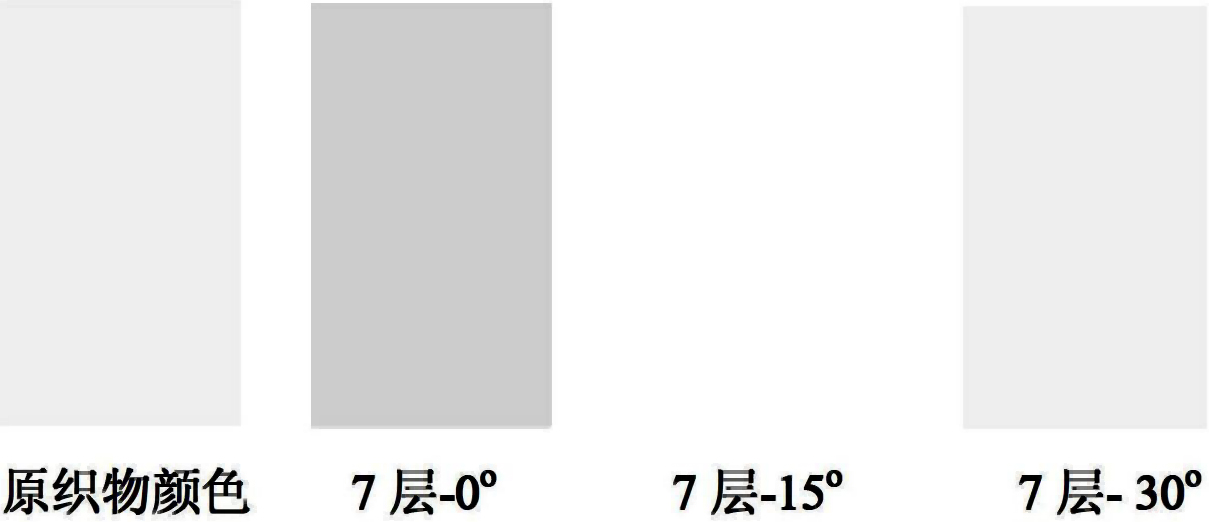

[0031] Use a dropper to drop a certain amount of prepared titanium sol solution on the surface of the cotton fabric in the self-rotating device, adjust the rotation speed to control the thickness of the titanium dioxide film layer to 60 nanometers; then dry at 30°C to stabilize the film structure on the surface; Wash in alcoho...

Embodiment 2

[0033] Dissolve 50 g of tetrabutyl titanate in 8.5 g of acetic acid, add the acetic acid solution of tetrabutyl titanate dropwise to 120 g of water, 16 g of ethanol and 0.1 g of hydrochloric acid under mechanical stirring at 500 rpm, and mix them evenly , stirred at room temperature for 3 hours, and aged for 24 hours to obtain a transparent titanium-containing sol.

[0034] Dissolve 11 g of tetraethyl orthosilicate in a mixture of 20 g of ethanol and 30 g of water under mechanical stirring, adjust the pH to 3.0 with hydrochloric acid, and mechanically stir at 500 rpm for 2 hours to form a stable and uniform silica sol.

[0035] Use a dropper to drop a certain amount of titanium sol solution on the surface of the cotton fabric in the self-rotating device, adjust the speed to control the thickness of the titanium dioxide film layer to 70 nanometers; then dry at 50°C to stabilize the film structure on the surface; Wash with deionized water for 5 minutes; drop the silica sol prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com