Mixed dry granules, dry granular glazed decorative ceramic tile with color crystal effect and preparation method

A ceramic tile and dry-grain glaze technology is applied in the field of ceramic tile decoration, which can solve the problems of dull decorative effect and lack of variety, and achieve the effect of bright color part.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

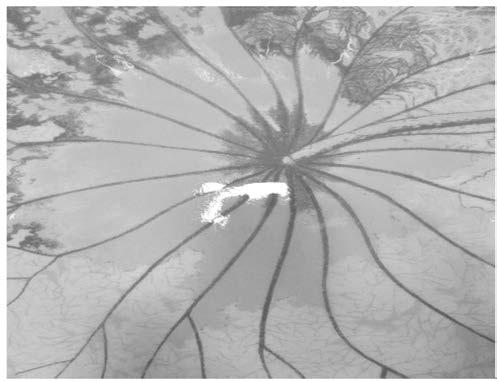

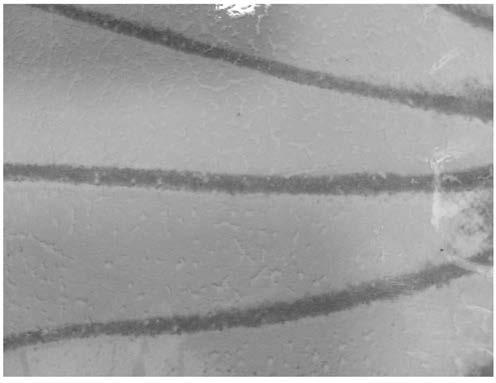

Image

Examples

Embodiment 1

[0057] 1. Pressed adobe with ordinary ceramic base material.

[0058] 2. Kiln drying, the drying time is 1 hour, and the moisture content of the dried billet is controlled within 0.5%.

[0059] 3. Spray surface glaze, chemical composition of surface glaze: loss on ignition: 8.33%; SiO 2 : 45.14%; Al 2 o 3 : 14.80%; Fe 2 o 3 : 0.21%; BaO: 9.04%; CaO: 9.25%; MgO: 3.50%; 2 O: 4.05%; Na 2 O: 2.05%; P 2 o 5 : 0.34%; ZnO: 3.29%, the specific gravity of the surface glaze is 1.41, and the glaze amount is 700g / m 2 .

[0060] 4. Inkjet printing pattern, using a digital inkjet printer (purchased from Flow Company) to print.

[0061] 5. By processing the design pattern in inkjet printing, extract the texture and curve in the design pattern through the route, and make a design vector file corresponding to the design pattern, and upload the processed design vector file to the digital glue dry In the granulator (purchased from Foshan Citibainte Ceramic Technology Co., Ltd.), a dig...

Embodiment 2

[0068] The difference from Example 1 is that the green dry granules are mixed with the transparent dry granules, and the dry granules are mixed according to the green dry granule: transparent dry granule=1:7 relationship to obtain the mixed dry granule frit, the green dry granule The melting point is 998°C, and the chemical composition of the green dry particles is by mass percentage: IL (loss on ignition): 3.41%; Na 2 O: 2.65%; SiO 2 : 60.31%; Al 2 o 3 : 12.70%; CaO: 9.19%; Cr 2 o 3 : 4.83%; K 2 O: 2.88%; ZnO: 1.38%; BaO: 1.19%; MgO: 1.10%; 2 o 3 : 0.23%; PbO: 0.13%. Particle gradation: 60-80 mesh: 30%, 80-100 mesh: 21%, 100-120 mesh: 24%, 120-250 mesh: 25%, 250 mesh or more: 0%. The melting point of transparent dry particles is 1130°C, and the chemical composition is by mass percentage: 1.25%; SiO 2 : 64.85%; Al 2 o 3 : 11.55%; CaO: 10.94%; Fe 2 o 3 : 0.15%; TiO 2 : 0.07%; MgO: 1.73%; K 2 O: 7.53%; Na 2 O: 0.03%; ZnO: 1.89%; ZrO 2 : 0.01%, the particle grada...

Embodiment 3

[0072] The difference in embodiment 1 is that the blue dry granule is mixed with the transparent dry granule, and the two dry granules are mixed according to the blue dry granule: transparent dry granule=3:7 relationship to obtain the mixed dry granule frit, the blue dry granule The melting point of the pellets is 1035°C, and the chemical composition of the blue dry pellets is by mass percentage: IL (loss on ignition): 0.71%; Na 2 O: 7.49%; SiO 2 : 70.40%; Al 2 o 3 : 16.30%; CaO: 1.32%; K 2 O: 1.22%; ZnO: 0.56%; BaO: 1.11%; CeO 2 : 0.17%; Fe 2 o 3 : 0.16%; Cl: 0.16%; MgO: 0.15%; TiO 2 : 0.13%; P 2 o 5 : 0.12%. Particle gradation: 60-80 mesh: 30%, 80-100 mesh: 20%, 100-120 mesh: 25%, 120-250 mesh: 25%, 250 mesh or more: 0%. The melting point of transparent dry particles is 1147°C, and the chemical composition is 1.23% by mass percentage; SiO 2 : 64.82%; Al 2 o 3 : 11.60%; CaO: 10.56%; Fe 2 o 3 : 0.15%; TiO 2 : 0.07%; MgO: 1.73%; K 2 O: 7.53%; Na 2 O: 0.05%; Zn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com