Machining method of wrapped structural flax and polyester filament section color composite yarn and composite yarn

A processing method and technology of composite yarn, which is applied in the field of composite yarn, can solve problems such as weaving preparation and weaving difficulties, and achieve the effects of saving water and electricity consumption and dye consumption, maintaining smoothness, and reducing yarn hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

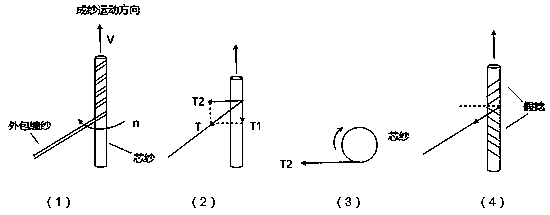

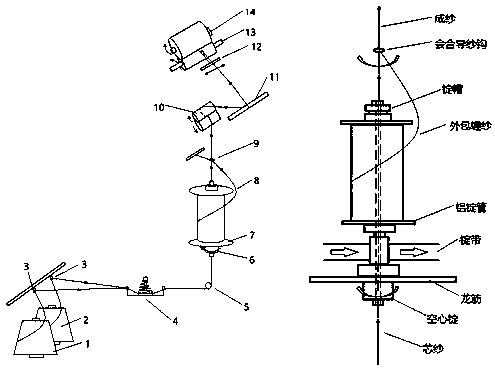

Method used

Image

Examples

Embodiment

[0092] The linen core yarn used is 36Nm wet-process long-linen bleached linen yarn, and its yarn blackboard is as follows: Figure 4 and Figure 5 shown. It can be seen from the figure that the yarn has obvious uneven thickness characteristics (evenness unevenness is 35.65%, -50% details reach 3791.7 pieces / km, 400% thick places reach 140 pieces / km), and the yarn hairiness is more (The hairiness value H reaches 2.45mm / cm).

[0093] The specification of the polyester core yarn used is 150D / 48F, and the variety is FDY. Red, blue, green three colors and flax yarn are respectively used to form double-core yarn for wrapping processing.

[0094] The wrapping yarn is polyester monofilament with a diameter of 0.08mm and a linear density of 69dtex.

[0095] The main process is: the hollow spindle speed is 15435r / min, the yarn drawing speed is 28m / min, the wrapping twist is 551 twists / m, and the wrapping twist is S twist.

[0096] The appearance of the spun composite yarn is as fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com