Catalyst for producing methyl acetate as well as preparation method and application of catalyst

A technology of methyl acetate and catalyst, which is applied in the direction of catalyst activation/preparation, carbon monoxide or formate reaction preparation, molecular sieve catalyst, etc. It can solve the problems that the catalyst is easy to deactivate and cannot meet the needs of industrial production, and achieve the reduction of catalyst The dosage, catalyst stability is good, and the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

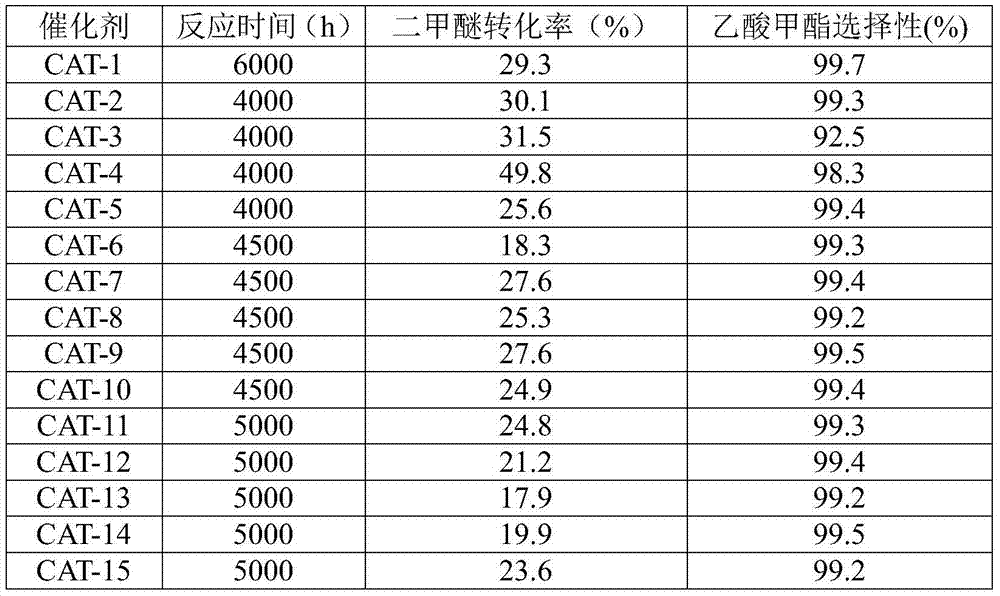

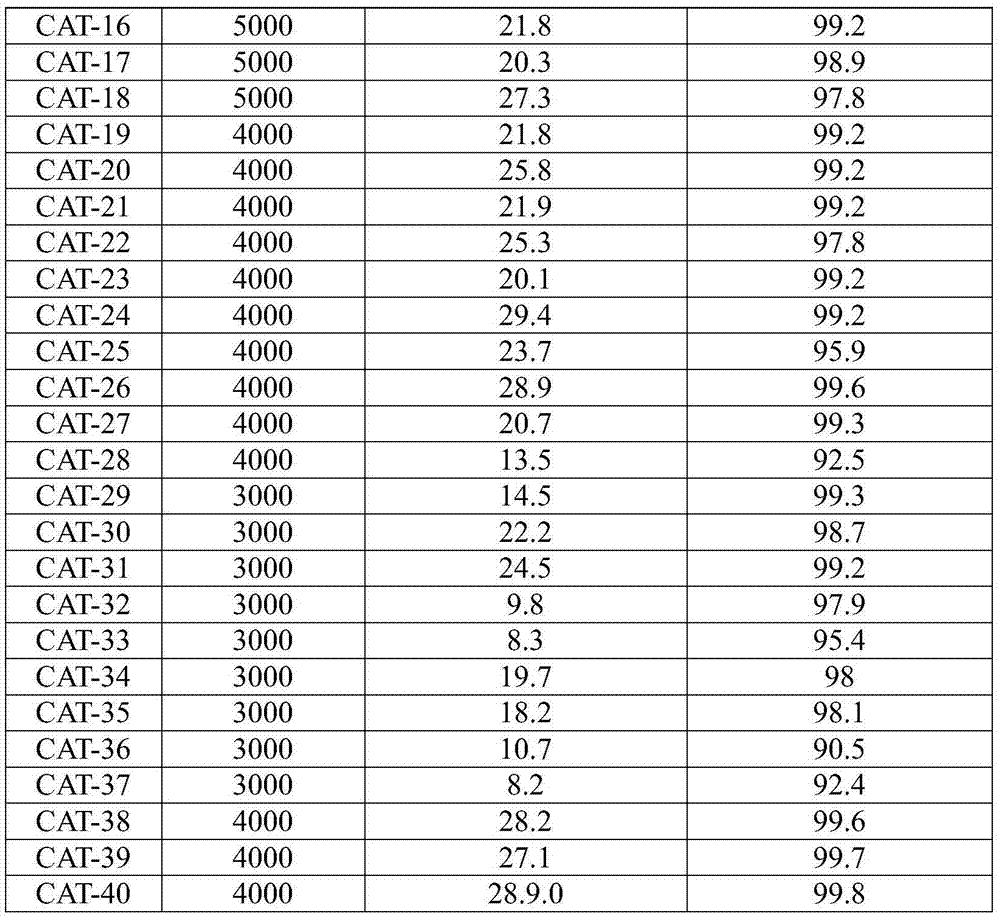

Examples

Embodiment 1

[0041] The preparation of embodiment 1 EMT molecular sieve

[0042]According to the method in the document Synthesis of silica-rich faujasite using crown-ethers astemplates: F.Delprato et, ZEOLITES, 1990, VO1 10:546, an EMT molecular sieve with a silicon-aluminum ratio of 4.2 was prepared.

[0043] EMT molecular sieves with silicon-aluminum atomic ratios (Si / Al) of 10, 15, 20, and 30 were obtained through dealumination of water vapor at 600° C. for 1 hour, 2 hours, 4 hours, and 8 hours.

Embodiment 2

[0044] The preparation of embodiment 2 catalyst CAT-1

[0045] Put 100 grams of EMT molecular sieves (Si / Al=15) into 1000 mL of 0.5 mol / L acetic acid solution at 80° C. for 2 hours, filter and wash until neutral. Then, it was baked at 120°C and 550°C for 4 hours in an air atmosphere. Get sample 80g of the good sample of acid treatment, 28g pseudo-boehmite (water content 29%) mixes evenly with 10% dilute nitric acid and then extrude into strips, dry at 120°C, and roast at 550°C for 4 hours to prepare the sample at 300°C , Pyridine and nitrogen with a volume ratio of 1:5 for 2 hours, recorded as catalyst CAT-1.

Embodiment 3

[0046] The preparation of embodiment 3 catalyst CAT-2~CAT-5

[0047] The specific preparation method and conditions are consistent with the catalyst CAT-1 in Example 2, except that the EMT molecular sieve with a silicon-aluminum ratio of Si / Al=4.2 is used, and the acid solution is a 0.5mol / L hydrochloric acid solution, and the obtained sample is recorded as a catalyst CAT-2.

[0048] The specific preparation method and conditions are consistent with the catalyst CAT-1 in Example 2, the difference is that the EMT molecular sieve with a silicon-aluminum ratio of Si / Al=10 is used, the acid solution is a 0.5mol / L nitric acid solution, and the obtained sample is recorded as a catalyst CAT-3.

[0049] The specific preparation method and conditions are consistent with the catalyst CAT-1 in Example 2, except that the EMT molecular sieve with a silicon-aluminum ratio of Si / Al=20 is used, and the acid solution adopts oxalic acid solution of 0.5mol / L, and the obtained sample is recorded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com