Wound repair liquid and preparation method thereof

A technology for wound repair and content, which is applied in the direction of medical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve problems such as unclear action, denaturation, and loss of activity, and achieve shortening healing time, Promotes repair and regeneration, and accelerates wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

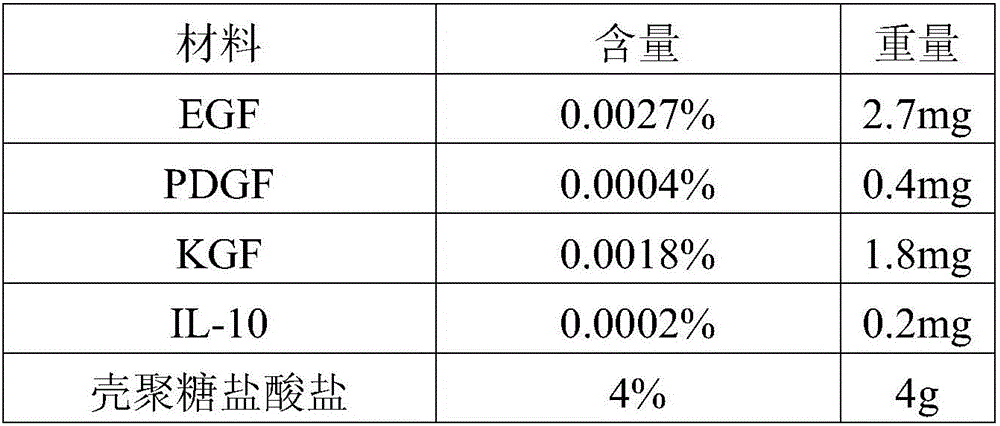

[0056] Embodiment 1 A kind of wound repair liquid

[0057] Formula, each 100mL contains:

[0058] Material

content

weight

EGF

0.0018%

1.8mg

PDGF

0.0004%

0.4mg

KGF

0.0018%

1.8mg

IL-10

0.0004%

0.4mg

4%

4g

PVP K25

1.5%

1.5g

0.01ppm (silver ion)

1.57μg

0.05%

0.05g

Polyglutamic acid (700kD)

0.05%

0.05g

KCl

80mM

0.597g

[0059] Preparation:

[0060] (1). 4g chitosan hydrochloride and 1.5g PVP K25 were dissolved in 50mL and 10mL deionized water respectively to obtain chitosan hydrochloride aqueous solution A and PVP K25 aqueous solution B;

[0061] (2). Mix solution A and solution B obtained in step (1), and obtain solution C after mechanical stirring and mixing at 45° C. and 1200 rpm;

[0062] (3). Reduce the stirring speed to 500rpm, lower the temperature to control the ...

Embodiment 2

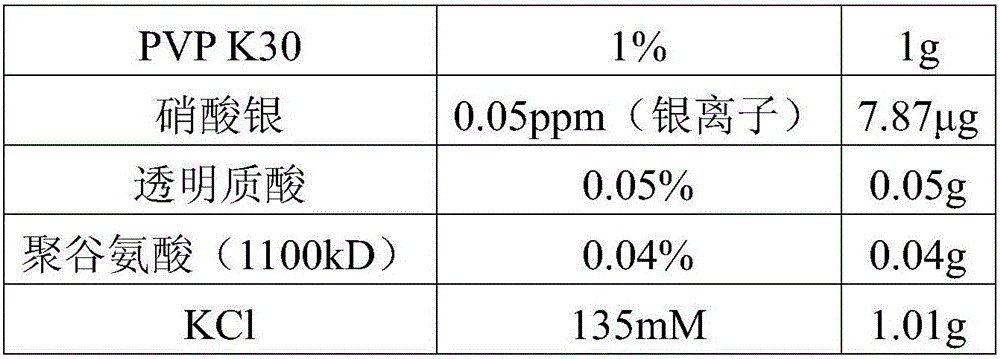

[0064] Embodiment 2 A wound repair liquid

[0065] Formula, each 100mL contains:

[0066] Material

[0067]Preparation method: basically the same as in Example 1, the temperature of mechanical stirring in step (2) is 45°C, and the speed is 1200rpm; the speed of step (3) is reduced to 400rpm, and the temperature of solution C is lowered to control the temperature not higher than 35°C.

Embodiment 3

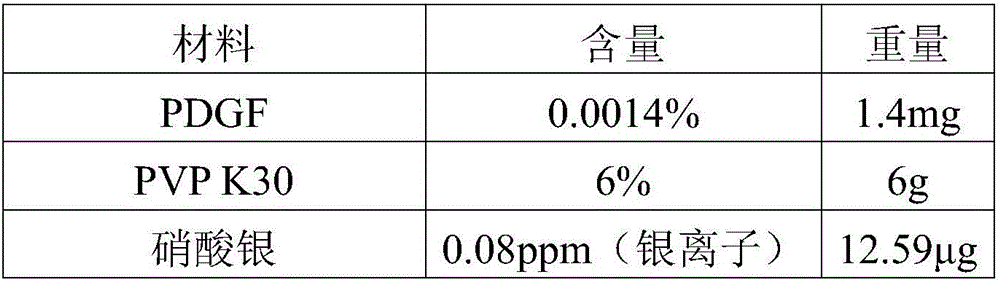

[0068] Embodiment 3 A kind of wound repair liquid

[0069] Formula, each 100mL contains:

[0070]

[0071]

[0072] Preparation method: basically the same as in Example 1, the mechanical stirring temperature in step (2) is 40° C., and the speed is 1500 rpm; the speed in step (3) is reduced to 600 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com