Scanning type laser vision sensing-based narrow-gap deep-groove automatic laser multilayer welding method for thick plate

A technology of visual sensing and welding method, applied in the field of welding and automatic welding, can solve the problem of low groove setting accuracy, easy to appear shading phenomenon, and can not realize the planning and welding of laser multi-layer welding bead with narrow gap and deep groove. and other problems, to achieve the effect of simple and easy welding process, no blind spots, high flexibility and independence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

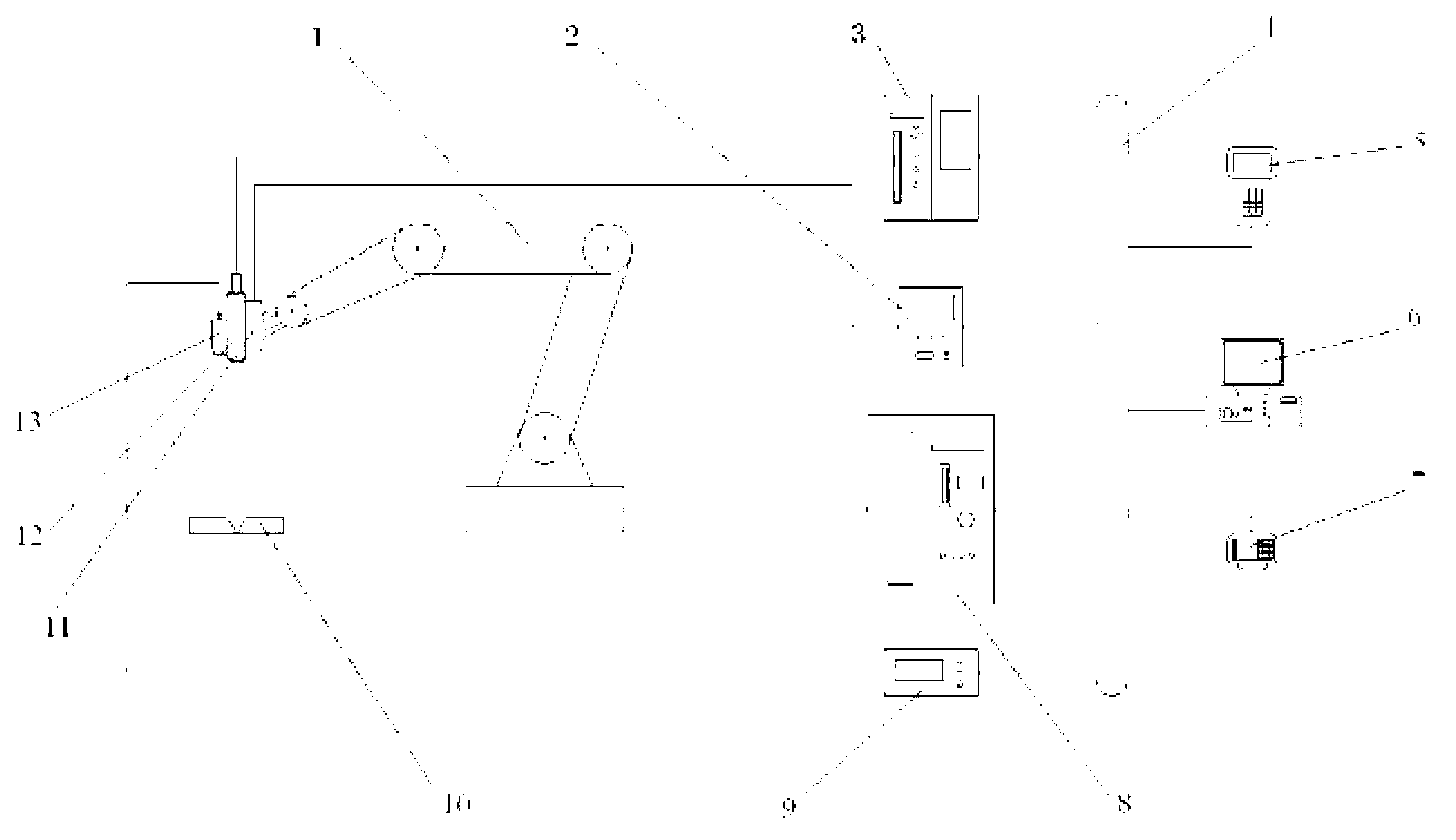

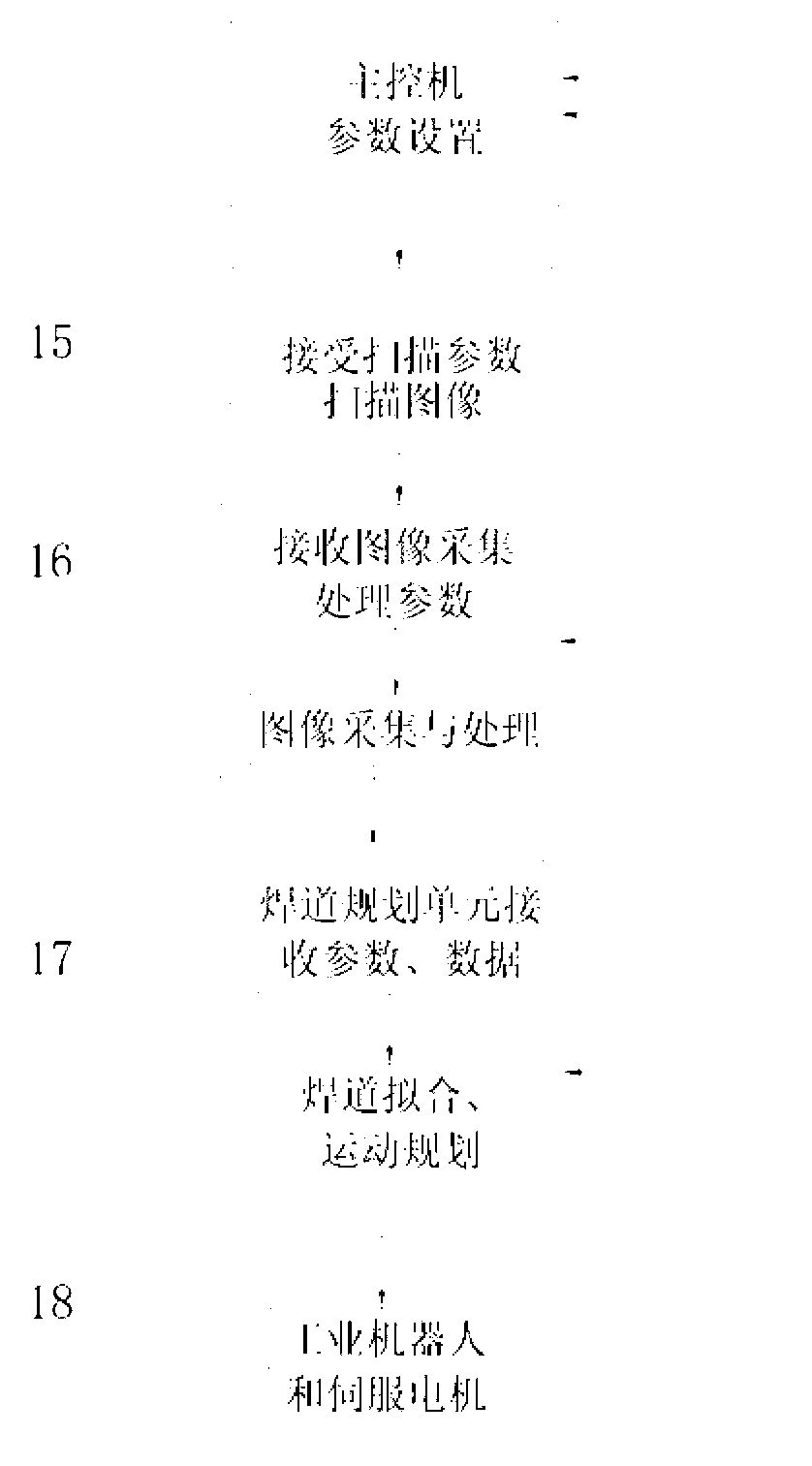

[0027] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Image 6 with Figure 12 To illustrate this embodiment, the specific steps of the laser automatic multi-layer welding method for thick plate narrow gap deep groove laser automatic multilayer welding based on scanning laser vision sensing in this embodiment are:

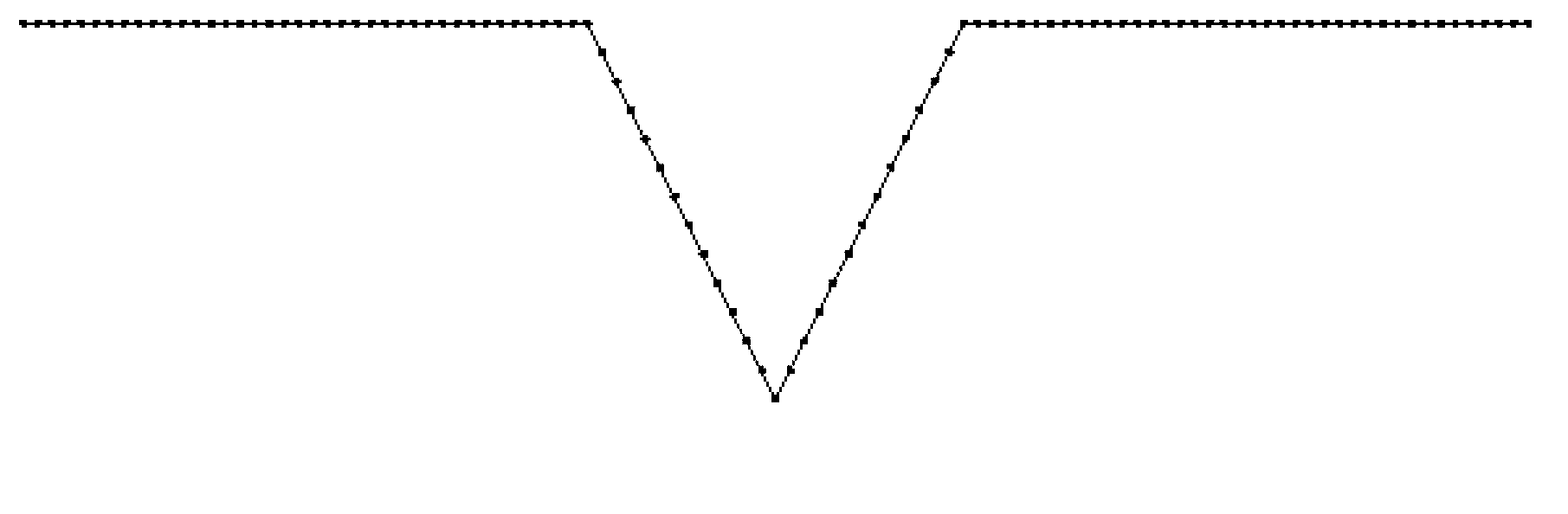

[0028] Step 1. Select the groove form as V-shaped groove, and set parameters through parameter setting and control unit;

[0029] Step 2: The image scanning unit scans the cross-sectional image of the groove of the thick plate workpiece to be welded, and obtains an array of 512 points for each scan, the range of abscissa is 0~511, and the range of ordinate is 1~1024. The coordinates are arranged in sequence, which is the two-dimensional image of the weld groove obtained by this scan;

[0030]Step 3, the image acquisition, processing and calculation unit performs real-time synchronous acquisition of the scanned V-shaped groove cross...

specific Embodiment approach 2

[0051] Specific implementation mode two: combination figure 1 , figure 2 , image 3 , Image 6 and Figure 12 Describe this embodiment. In Step 3 of this embodiment, perform image algorithm processing on the collected groove cross-section image to obtain weld image data. The specific process is: (1) Perform five-point centering on the collected groove cross-section image Value filtering denoising algorithm to process the filtered image, (2), use the slope-intercept algorithm to extract the feature points on the filtered image, first: first traverse all points on the filtered V-shaped cross-sectional image and find the lowest point , which is the first feature point b of the weld. Connect point b to coordinate point n on the Y axis corresponding to coordinate point 0 on the X axis of the two-dimensional coordinate system to form a straight line with a slope of K bn =(y b -y n ) / x b , through all points on the filtered image between point b and point n, make a straight l...

specific Embodiment approach 3

[0055] Specific implementation mode three: combination Image 6 and Figure 12 Describe this embodiment, in step 4 of this embodiment, the multi-layer welding bead planning unit performs the approximate simplification of the multi-layer welding bead to an equal area according to the characteristic parameters obtained by the image acquisition, processing and calculation unit and the preset number of weld layers The trapezoidal fitting calculation, the fitting algorithm is: weld bead feature point extraction, from the second feature point a and the third feature point c on the V-shaped cross-sectional image to the current weld bead collected by the acquisition unit between the two Traversing the points on the image, finding the two lowest points in the current weld bead are the first feature point i1 of the weld bead and the second feature point k1 of the weld bead, and then traversing the points between i1 and k1 to find the highest point among them, namely is the third featur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com