Universal arc welding robot teaching method regarding cylinder intersection welding seam

A teaching method and technology of intersecting lines, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of high trajectory interpolation accuracy, low trajectory interpolation accuracy, and low teaching efficiency, and achieve the goal of teaching The effect of high efficiency, small number and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

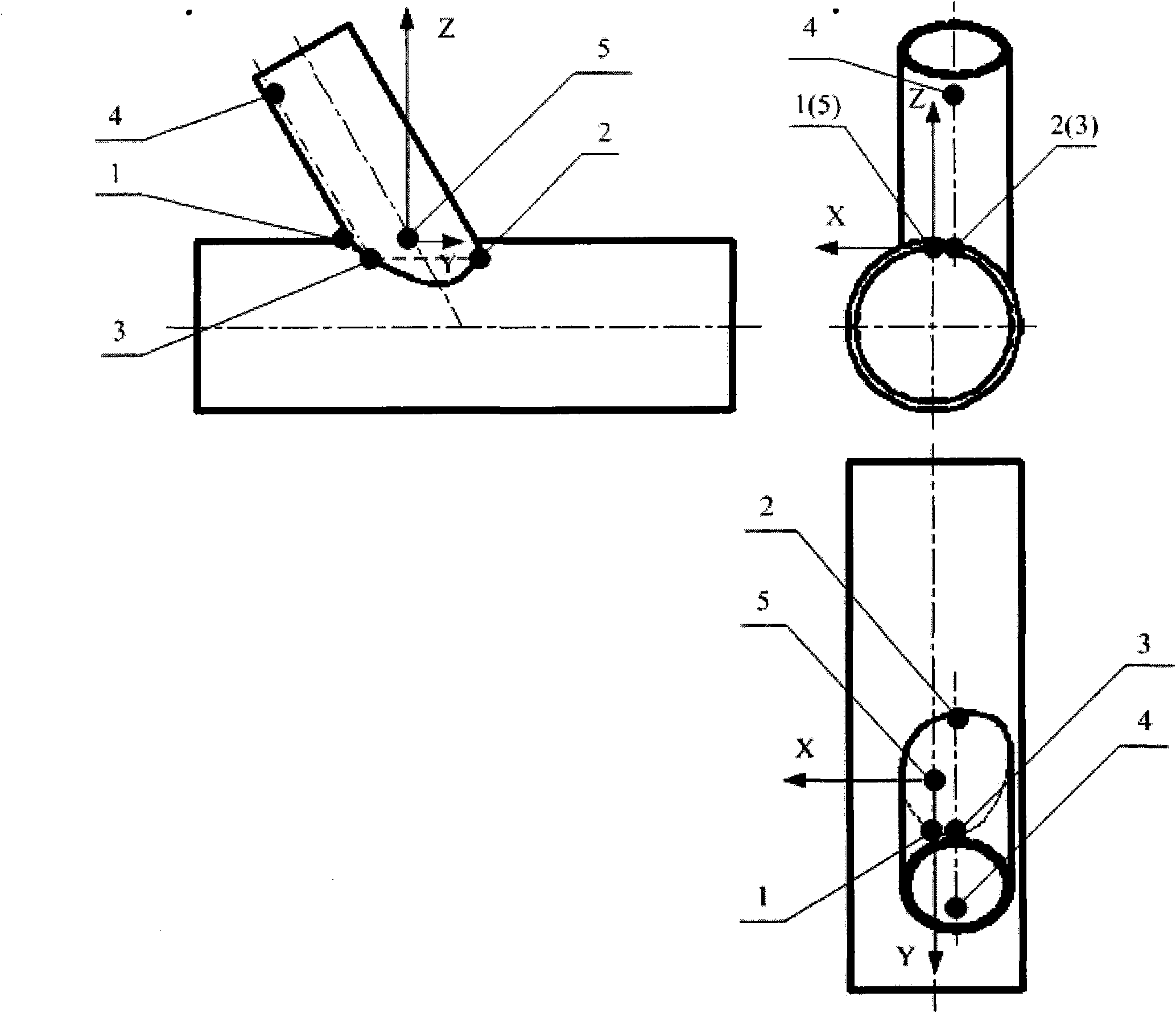

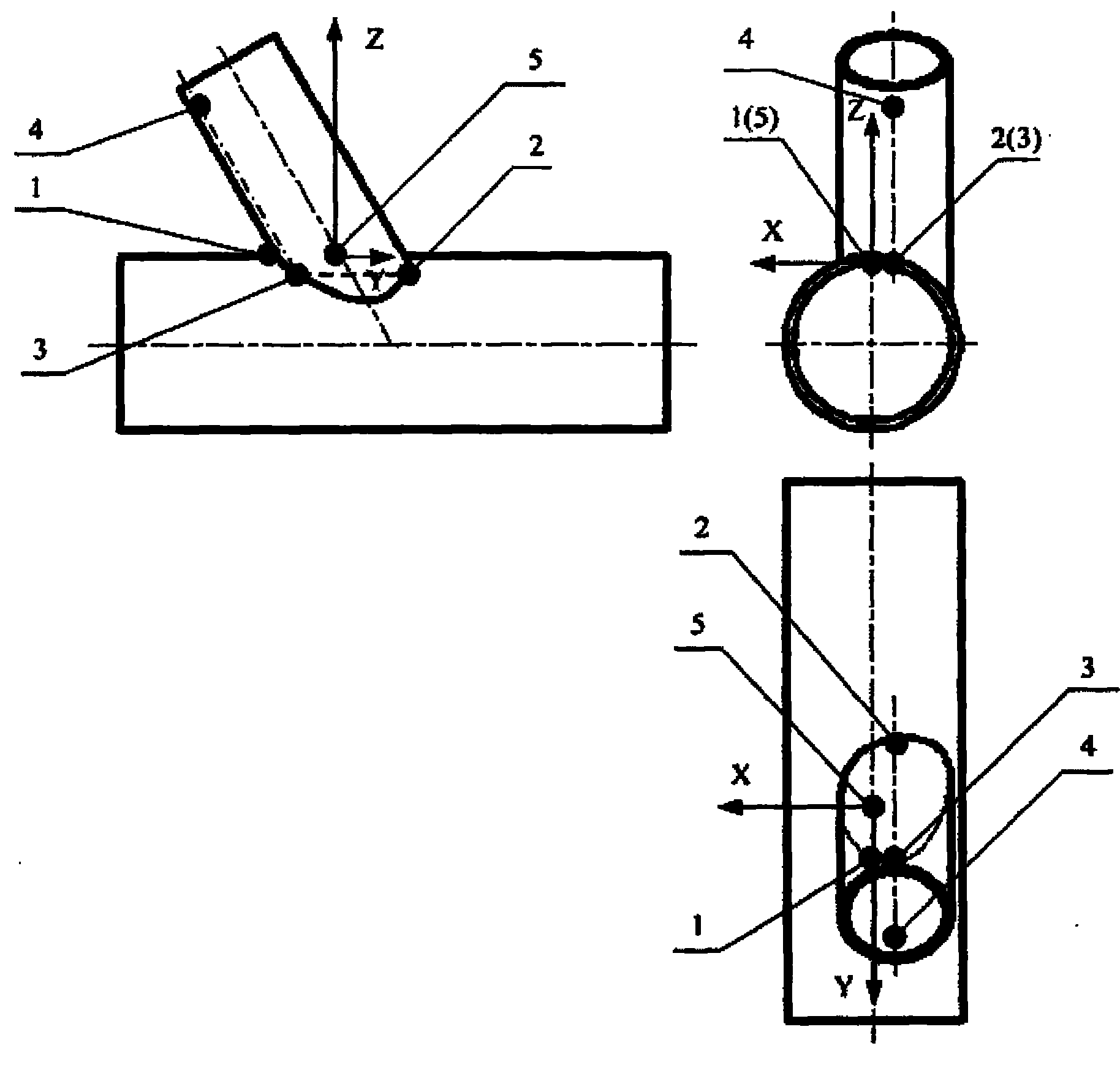

[0009] below for figure 1 The shown eccentric oblique intersecting cylinder intersecting line welded seam workpiece illustrates the specific method of the present invention.

[0010] see figure 1 , first identify the four feature points 1, 2, 3 and 4 on the workpiece of the cylindrical intersecting line weld, operate the arc welding robot to reach the position of the above feature points in turn, and teach the coordinate values of each feature point in the base coordinate system. Determine the origin 5 and Y axis of the workpiece coordinate system according to feature points 1, 2 and 3, and determine the X and Z axes according to feature points 3 and 4, so as to establish the pose transformation matrix of the workpiece coordinate system relative to the base coordinate system, and realize the cylinder Workpiece coordinate system calibration of intersecting line welds.

[0011] In the workpiece coordinate system, according to the polar coordinate analytical equation of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com