Longitudinal seam welding special machine with linear structure light type vision sensor and control method thereof

A visual sensor and line structured light technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of difficult welding seam tracking control, inability to obtain welding seam information, etc., and achieve the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

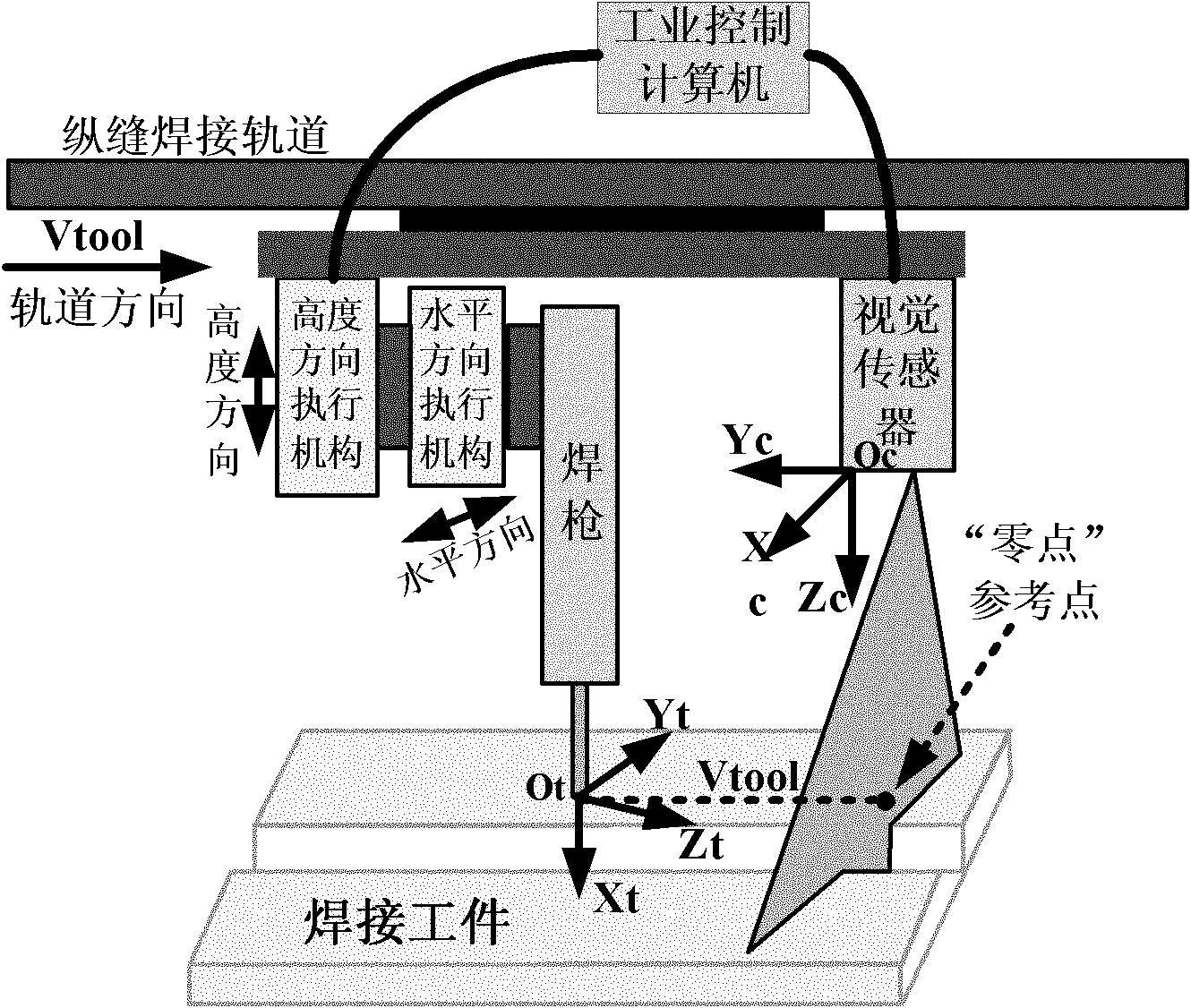

[0034] figure 1 Shown is a special machine for longitudinal seam welding with a line structured light vision sensor, including a welding torch, a line structured light vision sensor, an industrial control computer and an actuator. The welding torch is fixed on the actuator, and the welding torch and the line structured light The vision sensor is connected to the running track of the longitudinal seam welding machine, and the line structured light vision sensor is placed in front of the welding torch; the output end of the line structured light vision sensor is connected to the input end of the industrial control computer, and the output end of the industrial control computer End connection execution structure. The actuators are a group of actuators perpendicular to each other, which can simultaneously correct the height and horizontal direction of the welding torch. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com