Circular seam welding robot device

A kind of circular seam welding and robot technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of difficult temperature difference, small welding device, uneven welding seam forming, etc., to achieve precise control of welding speed and welding accuracy, Control the effect of welding thermal deformation and high-precision motion control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

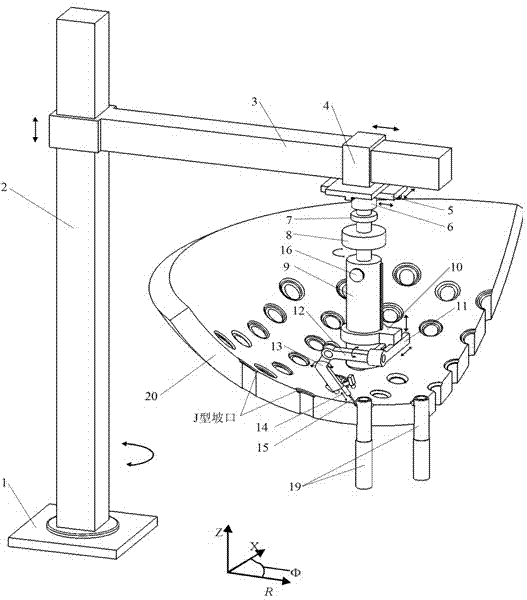

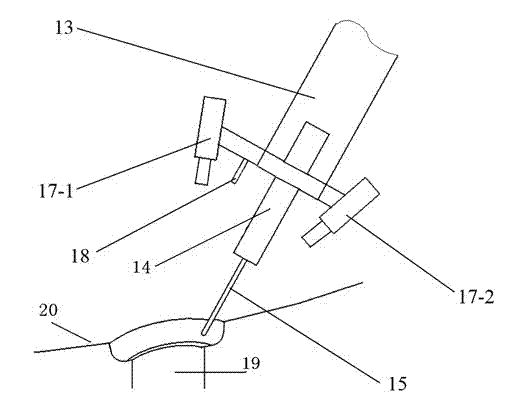

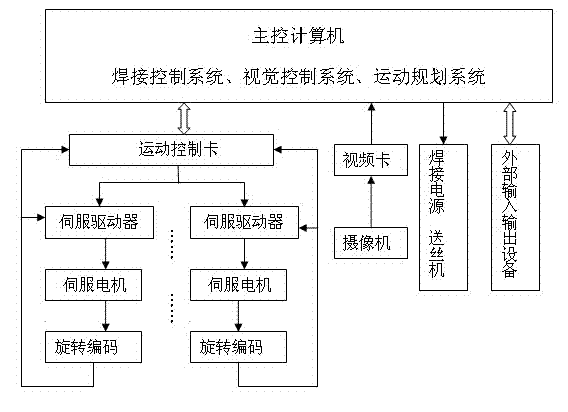

[0022] The structural principles of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments. The circular seam welding intelligent robot device consists of a fixed base 1, a column 2, and a beam 3 to form a frame. The column 2 rotates around the base 1, the beam 3 and the column 2 form a T-shaped frame with a slider structure, and the beam 3 moves up and down along the column 2. The sliding sleeve 4 is also inserted into the beam 3 with a slider structure, and the sliding sleeve can slide horizontally along the beam. A cross slide 5 is arranged below the sliding sleeve 4, and a fluid slip ring 7, a wire slip ring 8 and a circular motion shaft 9 are arranged coaxially below the cross slide 4 in sequence. The vertical motion shaft 10 is nested outside the circular motion shaft 9 , and the vertical motion shaft 10 can move up and down along the outer guide rail of the circular motion shaft 9 . A radial directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com