Forklift pallet fork distance adjusting device with video system

A technology of distance adjustment device and fork, which is applied in the direction of lifting device, etc., can solve the problems of complex equipment, large space occupation, and many auxiliary equipment.

Inactive Publication Date: 2017-12-22

JINGMEN CHUANGJIA MACHINERY TECH CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The fork distance adjustment devices for forklifts that have been applied for or authorized at present all use hydraulic devices or rotor motors to adjust the distance between a pair of forks.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

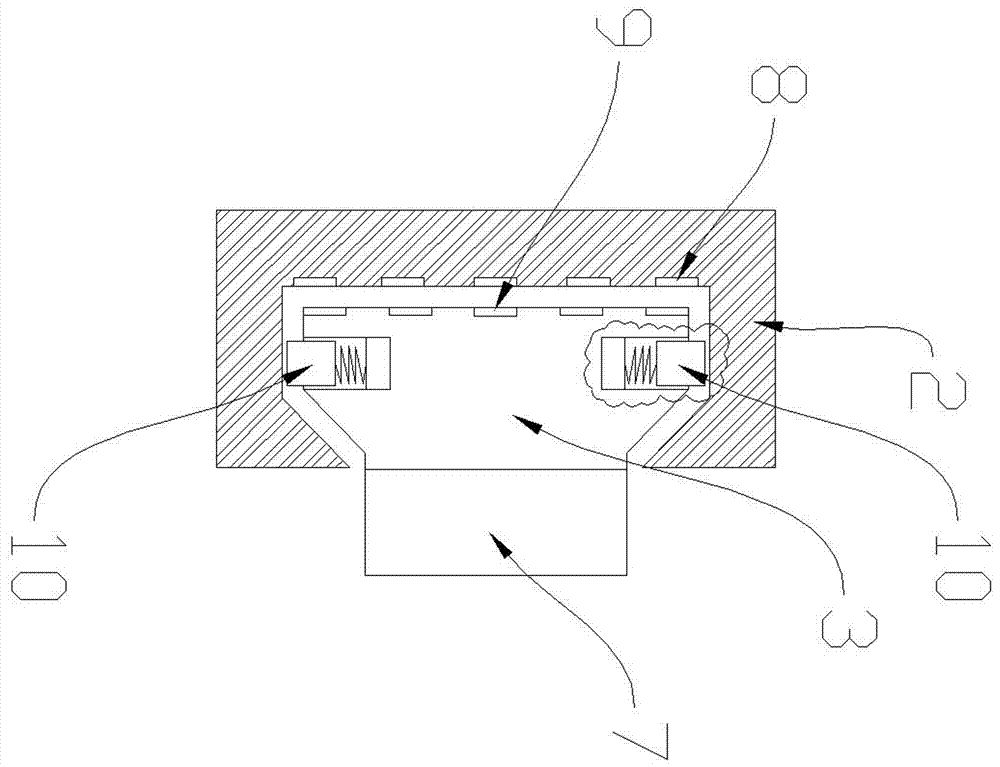

[0009] SUMMARY OF THE INVENTION The specific implementation of the present invention has been described in detail and will not be repeated here; it should be noted that the working principle of the linear motor is a known technology and will not be repeated here; the electromagnet anti-slip device 10 shares the power supply with the linear motor.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

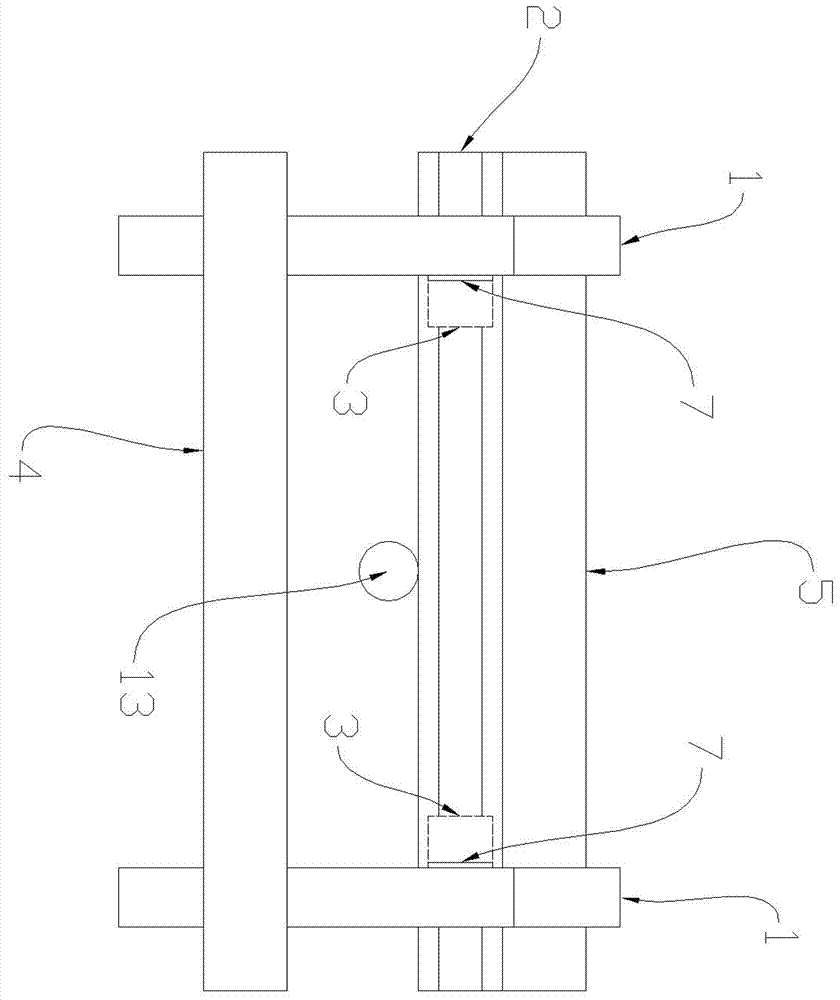

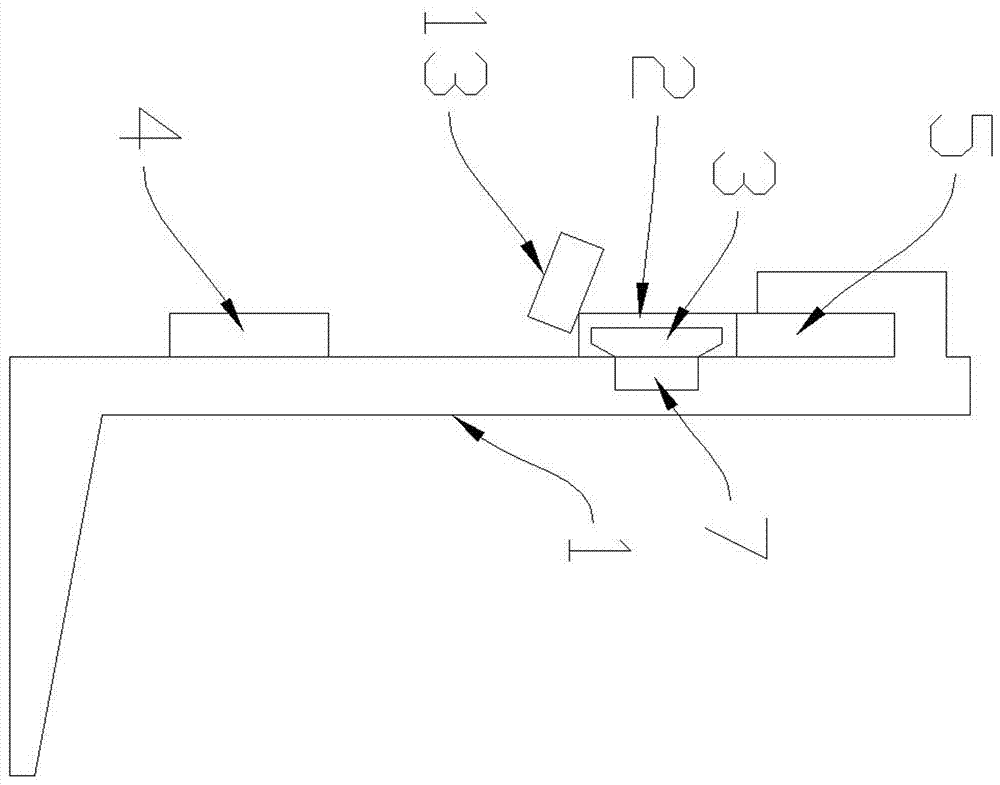

The invention discloses a forklift pallet fork distance adjusting device with a video system, and the forklift pallet fork distance adjusting device is mainly used for a forklift, adopts a linear motor to drive and adjust distance between a pair of pallet forks, adopts simple equipment, and further has a visual function. The forklift pallet fork distance adjusting device mainly comprises pallet forks, a linear motor stator, a linear motor rotor, a lower beam, an upper beam, a connecting plate, electromagnet non-slip devices and the video system. A working principle of the forklift pallet fork distance adjusting device is that: the linear motor rotor is accessed to a positive or negative power supply, the linear motor rotor moves leftwards or rightwards along the linear motor stator, and the connecting plate drives the pallet forks to move leftwards or rightwards, so that distance between left and right pallet forks is adjusted; after the distance is adjusted, power supplies of upper and lower pairs of electromagnet non-slip devices are started, so that electromagnets A of the upper and lower pairs of electromagnet non-slip devices are ejected to block upper and lower inner surfaces of the linear motor stator, and the linear motor rotor is prevented from sliding left and right, and therefore, left and right pallet forks are prevented from sliding left and right; and a driver observes whether the pallet forks are on correct positions or not through a video head.

Description

technical field [0001] The invention is mainly used for forklifts. Background technique [0002] The fork distance adjustment devices for forklifts that have been applied for or authorized at present all use hydraulic devices or rotor motors to adjust the distance between a pair of forks. . Contents of the invention [0003] The present invention overcomes the above-mentioned problems. It adopts a linear motor to drive and adjust the distance between a pair of forks. The equipment is simple, no auxiliary equipment is needed, and the space occupied is small. Stator (2), linear motor mover (3), lower beam (4), upper beam (5), connection plate (7), electromagnet anti-slip device (10), video system; a pair of forks (1) The upper end of the upper beam is hung on the upper beam (5), a pair of forks (1) can slide left and right along the upper beam (5), the upper end of the linear motor stator (2) is fixed with the lower end of the upper beam (5), and the linear motor stator ( ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B66F9/075B66F9/14B66F9/24

CPCB66F9/07504B66F9/146B66F9/24

Inventor 彭宝安

Owner JINGMEN CHUANGJIA MACHINERY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com