Bowel shears

A technology of intestinal scissors and scissors, applied in the field of medical supplies, can solve problems such as difficulty in accurately observing tissue conditions, easy hand fatigue, etc., and achieve the effects of not easy internal deformation, long service life, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

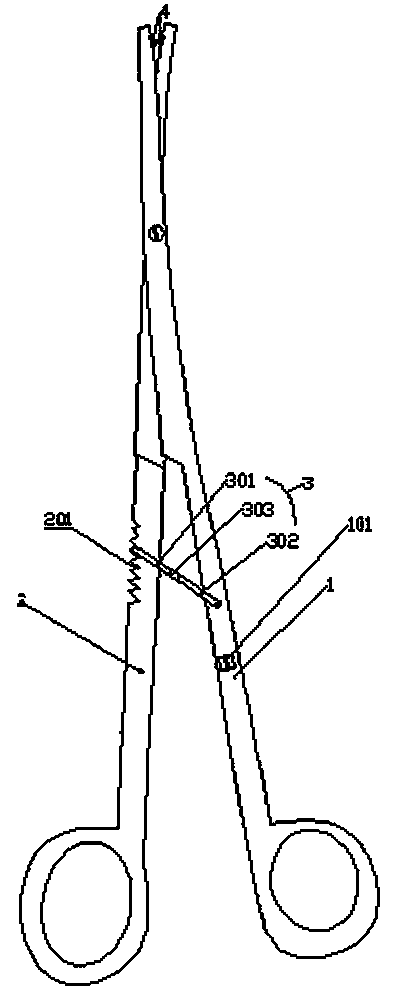

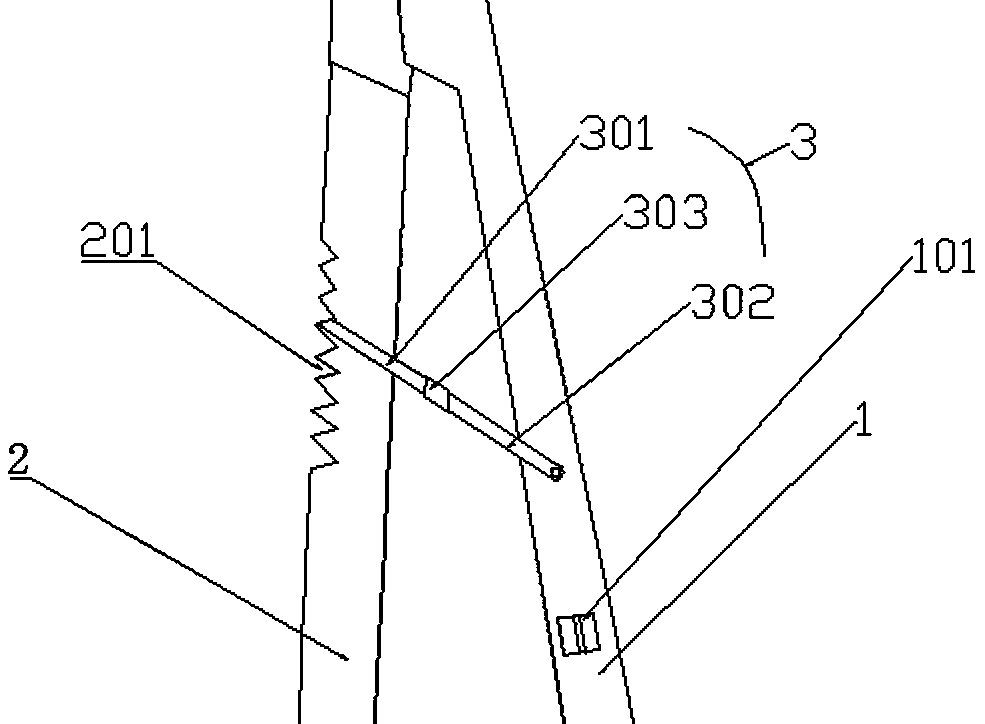

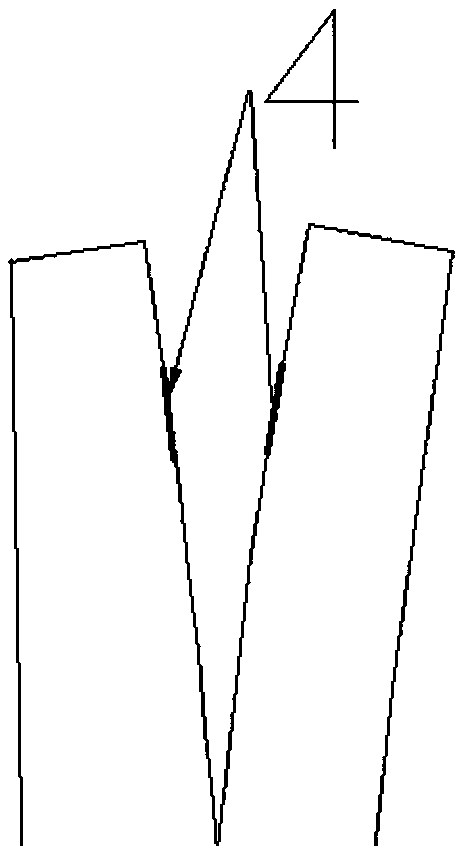

[0032] Specific embodiment 1: as Figure 1-2 As shown, a kind of intestinal scissors of the present invention comprises: a first scissors handle 1 and a second scissors handle 2, and the first scissors handle and the first scissors handle are hinged to form intestinal scissors; the ends of the intestinal scissors are two The inner side of the tough part is provided with a micro-camera 4, and the micro-camera and the tough part form a plane; the scissor handle on the second scissor handle 2 is provided with a locking tooth 201, and the locking tooth is a strip structure. The strip structure is provided with a continuous tooth gap; the first scissors handle is hinged with an adjustment rod 3, one end of the adjustment rod is hinged to the first scissors handle, and the other end is provided with a protrusion that can be stuck in the tooth gap. department. The first scissor handle is provided with a slot 101 capable of fixing the adjusting rod 3 , the slot is made of rubber mate...

specific Embodiment 2

[0034] Specific embodiment 2: A Ni-Fe-based superalloy material, in terms of mass percentage, the superalloy material includes the following alloying elements: C: 0.04-0.05%, Fe: 19.0-21.0%, Cr: 19.5-20.5% , Al: 0.90-1.05%, Ti: 2.65-2.80%, V: 0.20-0.30%, Mo: 2.0-2.5%, Nb: 1.50-1.70%, Y+Ce: 0.046-0.058%, B: 0.003-0.006 %, the balance is Ni and other impurities. Wherein, the superalloy material also includes P and S with a mass fraction less than 0.024%.

[0035] The preparation method of above-mentioned Ni-Fe base superalloy material, comprises the following steps:

[0036] 1) Weigh the raw materials according to the percentage of the components, adopt the existing preparation process for smelting high-temperature alloys, smelt them in a vacuum induction furnace at 1500°C, and pour the solution into alloy billets;

[0037] 2) Clean the surface of the alloy billet, then place it in a vacuum heating furnace and heat it to 810-820°C to remove the oxide skin on the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com