A vacuum chamber for graphene preparation with visualization of growth process

A technology of growth process and vacuum chamber, applied in the field of vacuum chamber, can solve the problems of no clamping device, invisible, poor portability, etc., and achieve the effect of stable working process, convenient portability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

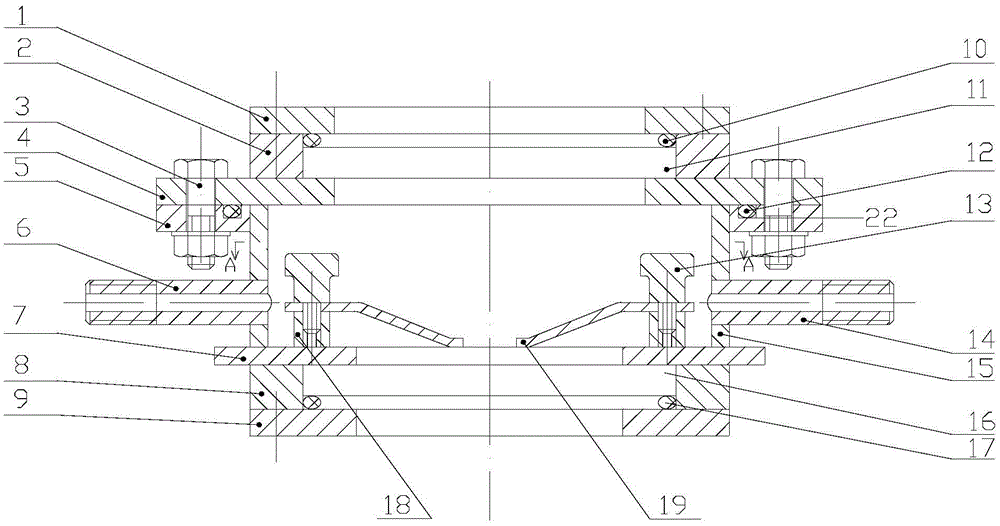

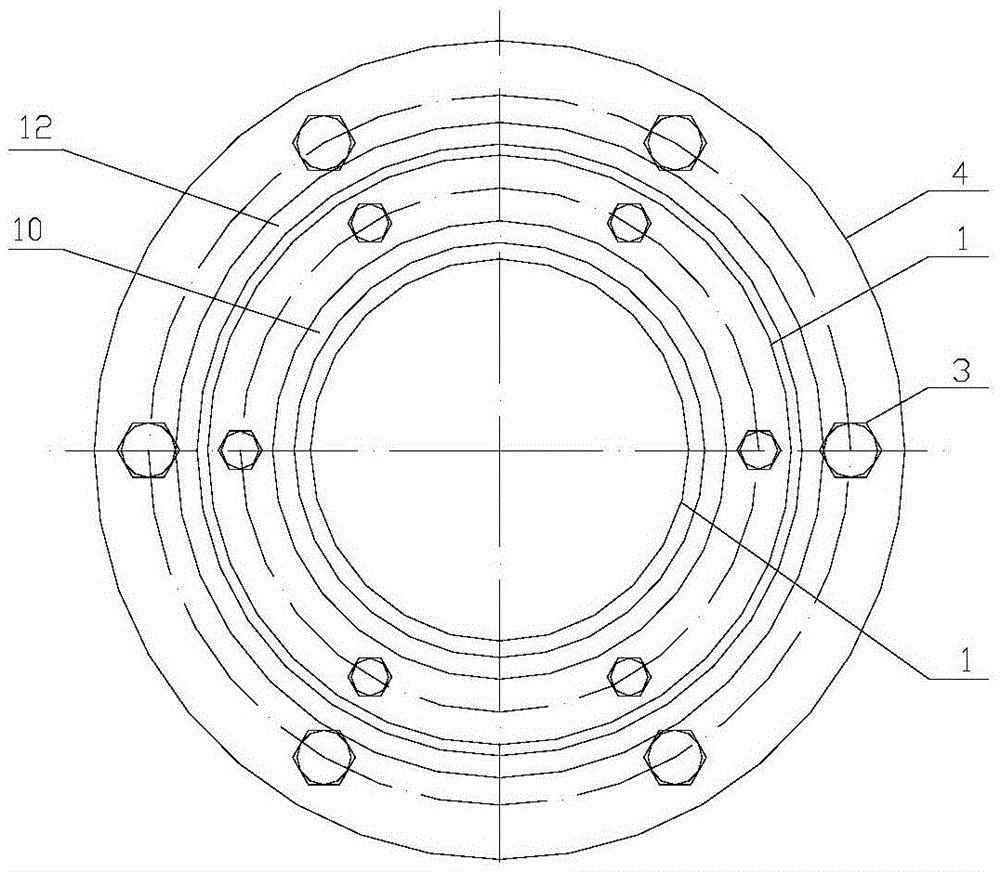

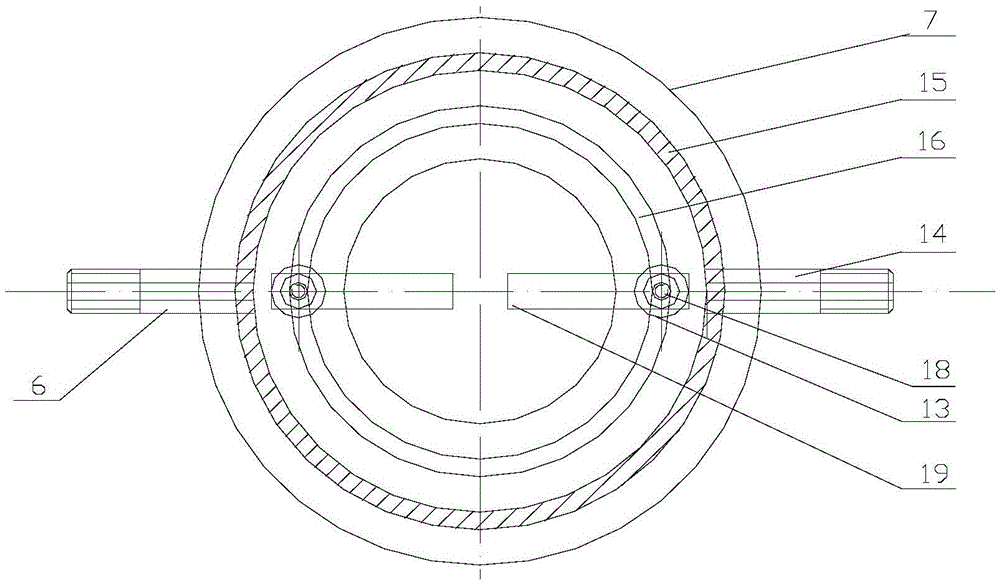

[0018] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

[0019] see Figure 1~3 , the embodiment of the present invention is provided with cavity 15, upper observation port 11, lower observation port 16, clamping device, intake valve 6, air outlet valve 14; The upper observation port 11 and the lower observation port 16 are passed through the upper observation port method The flange 4 and the lower observation port flange 7 are respectively welded to the cavity 15, the top of the cavity 15 is provided with a sealing flange 5, the sealing flange 5 is provided with an annular groove 22, and an upper observation port is provided in the annular groove 22. Lan sealing ring 12, the upper observation port flange 4 is connected with the sealing flange 5 through bolts 3, the upper observation port flange 4 is provided with the cavity upper flange 2, the upper observation port flange 4 and the cavity upper flange 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com