Automatic tracker of longitudinal seam welding for major diameter welding pipe

An automatic tracking device, longitudinal seam welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of increased production cost, missing welding, time-consuming and laborious, etc., to achieve reliable work, rigorous structure, and ensure welding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

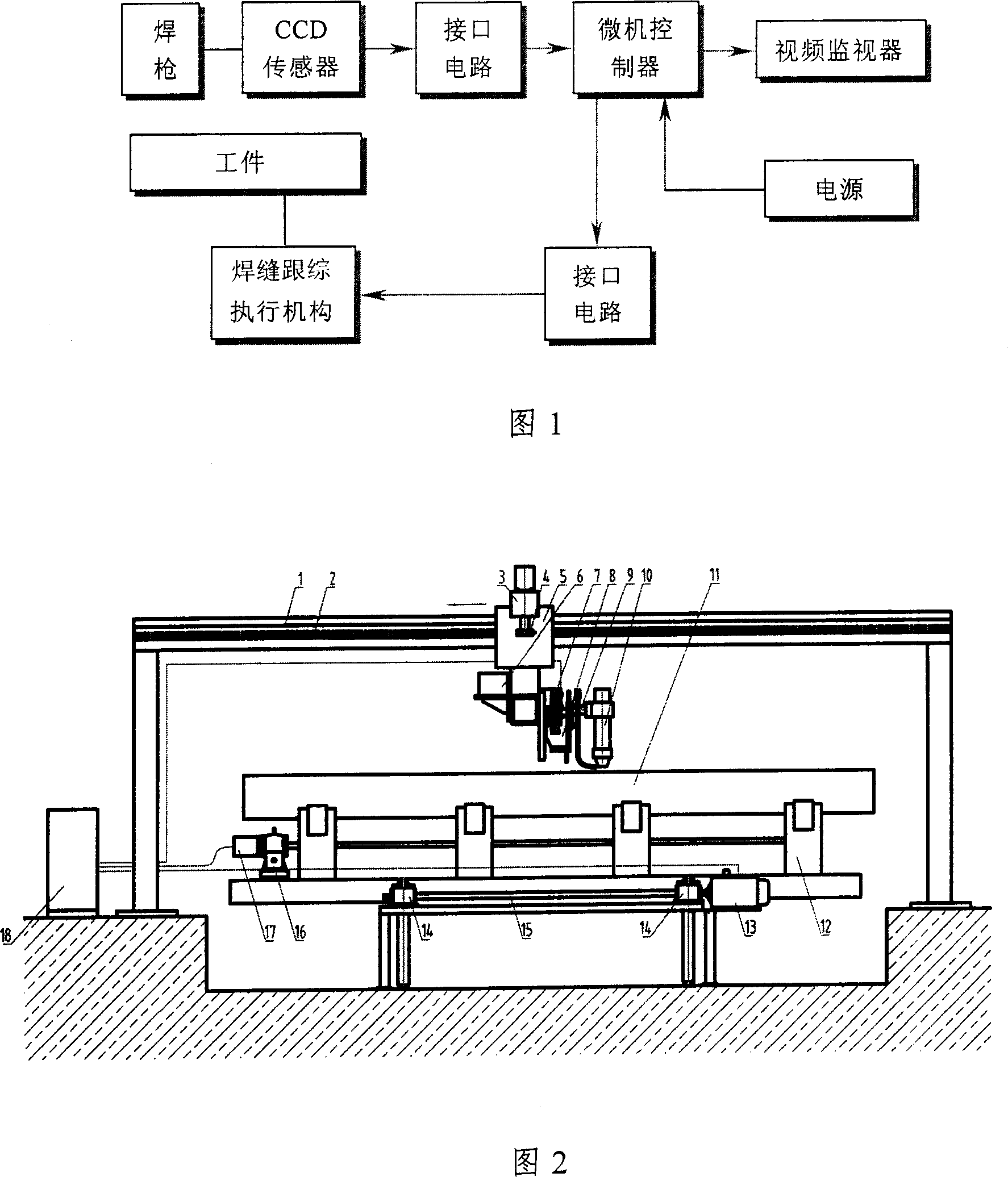

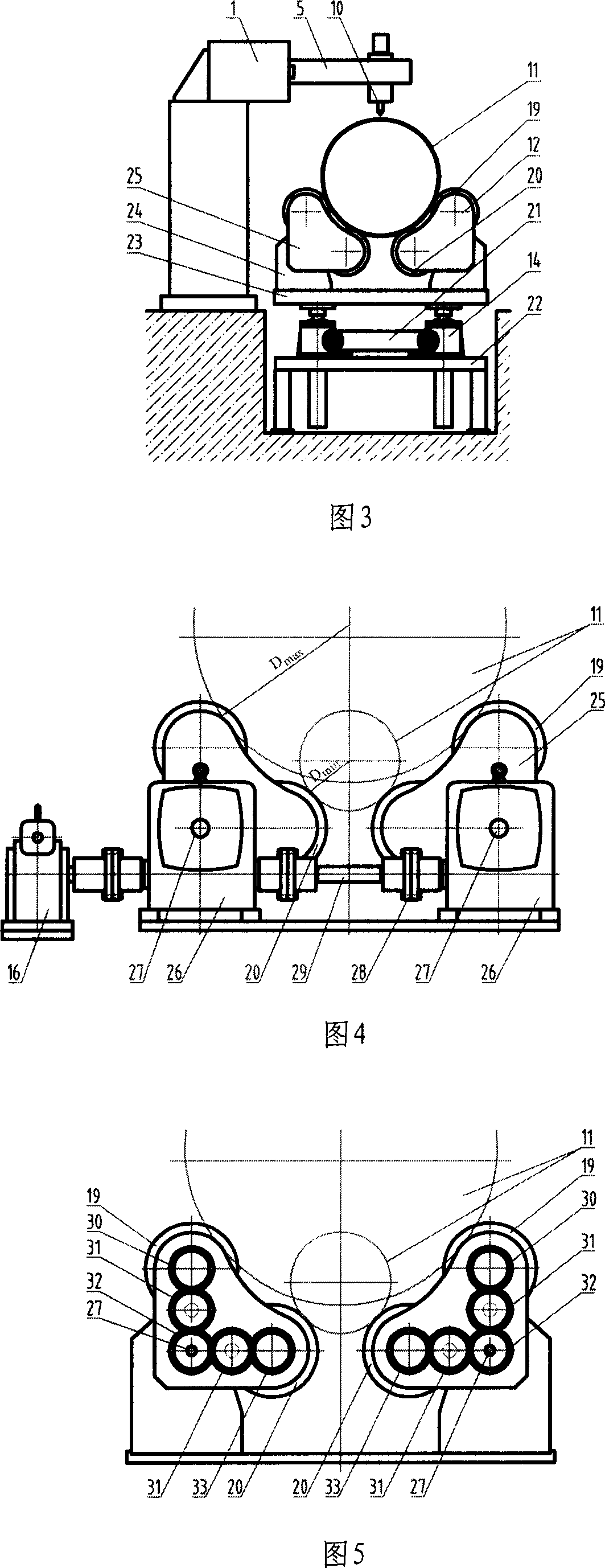

[0011] The present invention will be further described below with reference to the accompanying drawings.

[0012] A welding torch 10 and a welding wire conveying mechanism 9 are installed on the trolley 5, and the automatic tracking of the welding torch height of the welding torch 10 adopts AvC control, that is, arc voltage constant value control. A visual sensor 8 and a video monitor 6 are installed in front of the welding torch 10, and the visual sensor 8 is connected with a microcomputer controller 18 through an interface circuit. In this embodiment, the trolley 5 is also specially provided with a miniature cross slider 7 with a visual sensor 8, so that the relative position of the visual sensor and the welding torch can be adjusted in time through the laser stripes and welding seam positions in the video monitor 6. The driving mechanism 3 of the trolley 5 is composed of a servo motor and a reducer, and is meshed with the rack guide rail 2 on the gantry beam 1 above the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com