Die assembly upsetting and forging machine and working method thereof

An upsetting machine and upsetting technology, which is applied in the field of upsetting machines, can solve problems such as the complex structure of upsetting machines, the inability to upsetting formed parts, and the difficulty in high-speed upsetting, so as to improve the accuracy of equipment, improve driving reliability, The effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

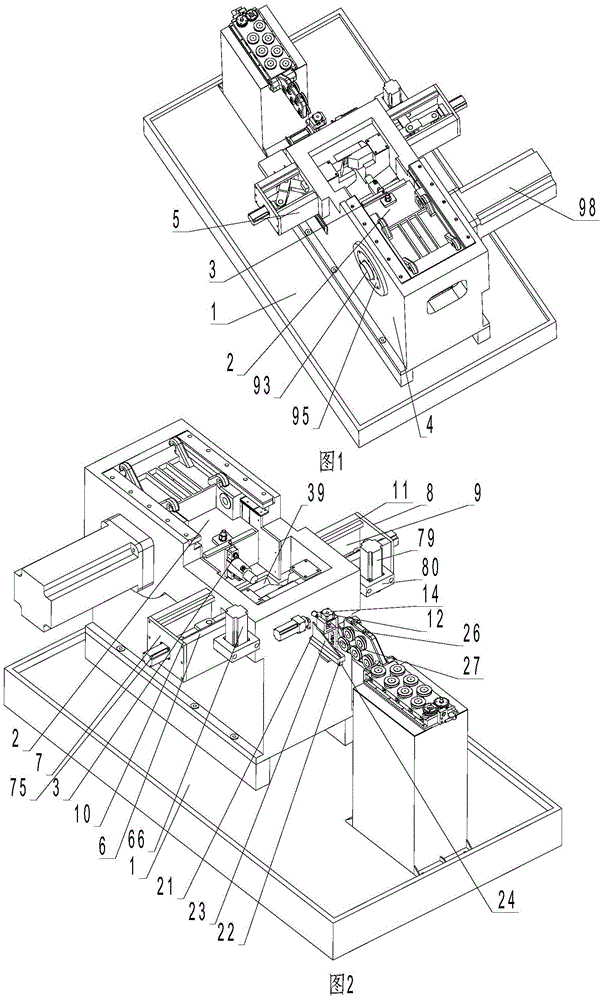

[0102] Such as figure 1 , figure 2 , Figure 9 As shown, a die-clamping upsetting machine for upsetting steel balls includes a body 1, a large slider 2 mounted on the body 1 that can slide back and forth, a die assembly 3 mounted on the large slider 2 and a large drive The large slide block drive mechanism that slide block 2 slides back and forth, the main mold assembly 3, the wire feeding mechanism that is installed on the body 1.

[0103] Such as figure 1 , figure 2 As shown, the body 1 includes a frame body 4 and a frame seat 5, and the frame seat 5 includes a frame body 6, an end plate 7, and an end plate 8, and the frame body 6 has an accommodating cavity 9, and the two sides of the accommodating cavity 9 The end portion has an opening 10 and an opening 11 , the end plate 7 is fixed on the base body 6 at the opening 10 , and the end plate 8 is fixed on the base body 6 at the opening 11 . Both ends of the frame body 6 protrude from the frame body 4 .

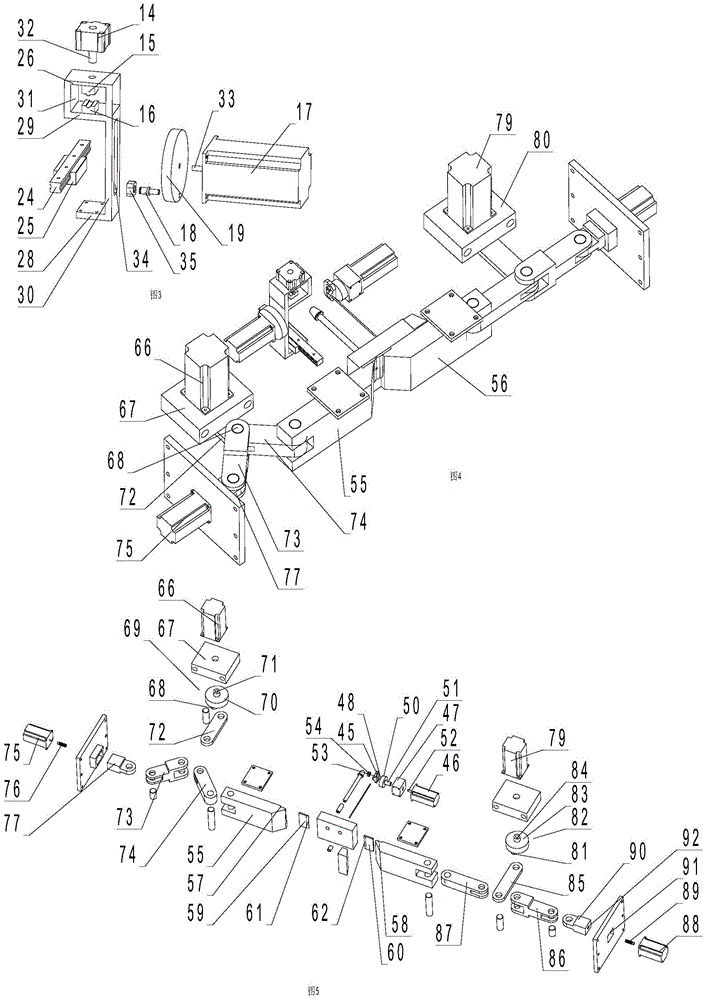

[0104] There a...

Embodiment 2

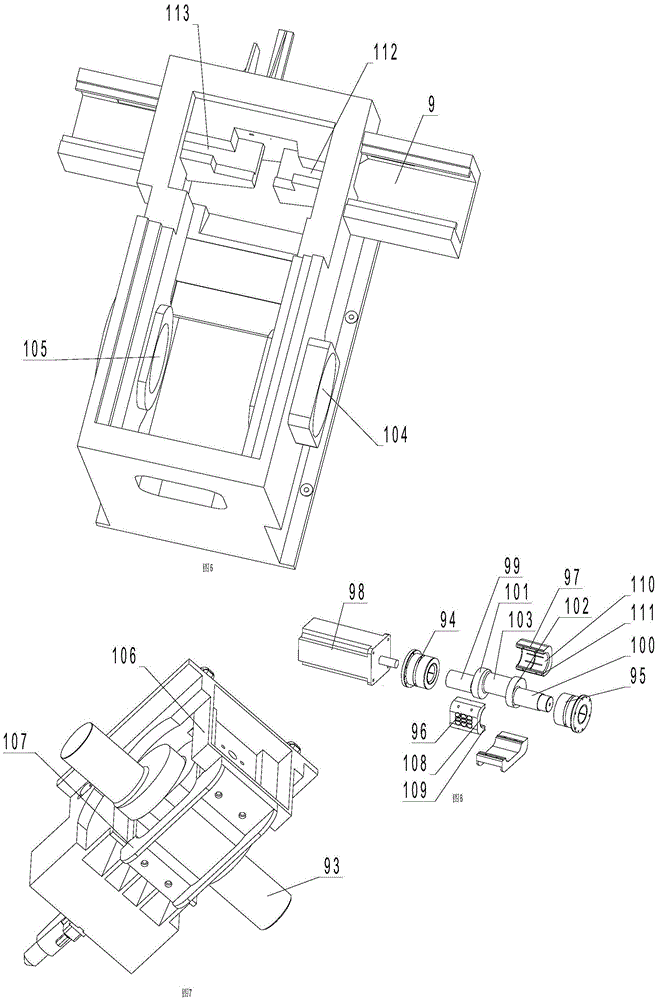

[0139] Such as Figure 10 to Figure 14 As shown, the difference from Embodiment 1 is that three stations are provided on the frame body 151 , a cutting station 152 , an upset forging station 153 , and an upset forging station 154 .

[0140] Such as figure 1 , Figure 4 , Figure 5 , Figure 9 As shown, the main mold assembly 3 includes a main mold base 155 fixed on the frame body 151, a trimming sleeve 156, and a mold clamping assembly. Corresponding to the trimming position 152 of the machine body 1, a trimming cover installation hole 157 is provided on the main mold base 155 . The shearing sleeve 156 is installed in the mounting hole 157 of the shearing sleeve. There is no upsetting die mounting hole on the main mold base 155, and no ejector mechanism is needed on the main mold assembly 170 side. .

[0141] The first installation space is set on the first clamping base 162 and opens towards the second clamping base 163, and penetrates the first groove 158 of the first...

Embodiment 3

[0155] Such as Figure 15 to Figure 19 As shown, the difference from Embodiment 2 is that, at the trimming position 201, the machine body 202 is also provided with a pneumatic feeding mechanism. The pneumatic blowing mechanism includes a cylinder support 203, a cylinder 204, and a blowing part 205. Cylinder support 203 is fixed on the top of the body 202 of cutting material position 201, and cylinder 204 is fixed on the top of cylinder support 203, and the fixed piston rod 206 with the piston of cylinder 204 passes cylinder support 203 and blows material 205 and fixes. The axis of the piston rod 206 of the cylinder 204 is perpendicular to the axis of the shear sleeve 207 .

[0156] The first mold clamping driving mechanism includes a first servo motor 209 that only drives the translation of the first mold clamping base 208 , a mounting base 210 , a first driving member 212 , and a first driving slider 214 . The first drive member 212 includes a first drive disc 213, a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com