Rotating cup bearing shell milling device for lathe

A bearing shell and lathe technology, applied to the milling device, positioning device, support, etc. that can be installed on the machine tool, can solve the problems of insufficient milling machine and no milling machine, and achieve the goal of improving processing efficiency, improving work efficiency and expanding the scope of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

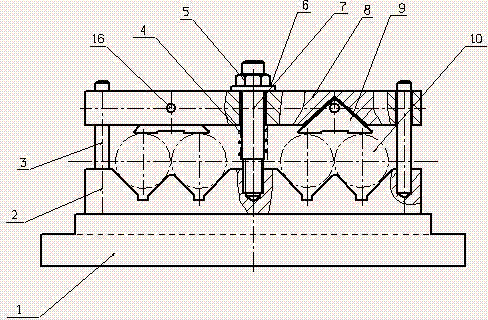

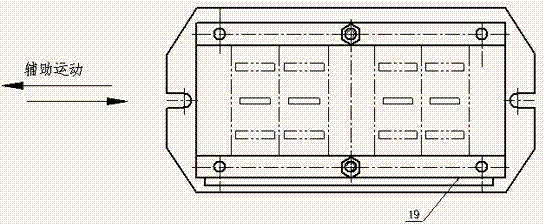

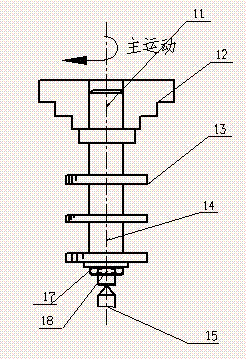

[0014] The milling device for the rotor cup bearing shell of the lathe according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] attached figure 1 The front view of the Doka clamp, the main part of the clamp shown in the figure is composed of a bottom plate 1, a V-shaped iron 2 and a frame-type pressure plate 8, wherein the V-shaped iron 2 is fixed on both sides of the bottom plate 1, and the V-shaped iron 2 is fixed on both sides There are several V-shaped grooves on the top, and each V-shaped groove is coaxially arranged with the V-shaped groove on the opposite side, and a workpiece is placed on each pair of V-shaped grooves. There are fixed screw holes in the middle of the V-shaped iron 2 on both sides, and fixed holes are formed at the corresponding positions of the longitudinal plates on both sides of the frame-type pressure plate 8, and the hold-down bolt 7 connects the frame-type pressure plate 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com