Method for helically milling hole and device thereof

A technology of helical hole milling and rotating drive device, applied in the direction of drive device, feeding device, milling machine equipment, etc., can solve the problems of decreased machining surface quality, accelerated tool wear failure, poor thermal conductivity of titanium alloy, etc. Hole quality and strength, fast heat dissipation effect

Inactive Publication Date: 2009-09-23

TIANJIN UNIV

View PDF0 Cites 40 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The diameter of the hole is generally 6~15mm. In the traditional drilling process, the linear speed of the spindle center is zero, that is, the center of the drill bit does not participate in cutting, and the removal of workpiece material in this central area depends entirely on the downward movement of the drill. It is extruded by the thrust, so the drill bit bears a very large Z-direction force during drilling. When processing high-hardness materials such as titanium alloys, rapid wear and failure of the tool is a common phenomenon.

In addition, the traditional drilling process is a continuous cutting process, the blade is always in contact with the workpiece, the temperature of the contact surface between the blade and the workpiece is very high during cutting, and the thermal conductivity of titanium alloy is relatively poor. The cutting process leads to the accumulation of temperature, which will also Accelerated tool wear failure leads to reduced machined surface quality

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

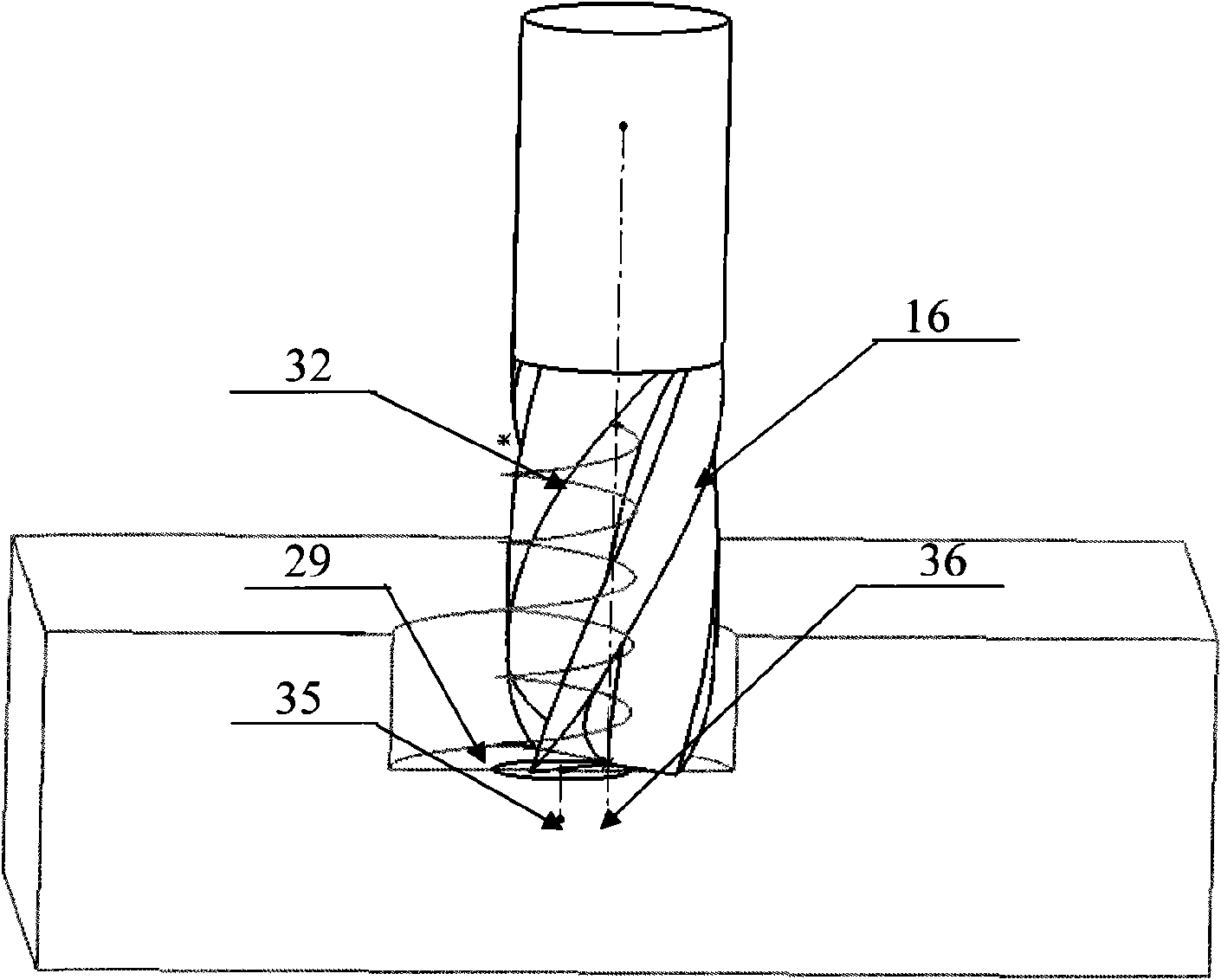

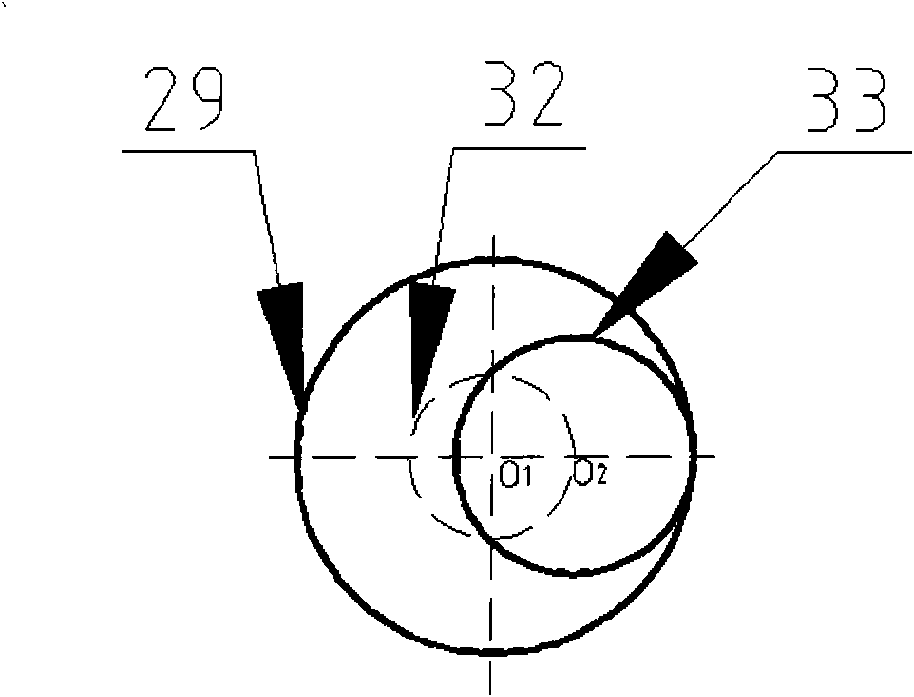

[0034] A hole with a diameter of 10 mm is machined using a tool with a diameter of 6 mm. First, the tool rotates around the center line of the tool and revolves around the machining hole; adjust the center line of the tool to deviate from the center line of the frame by 2mm and then continue processing. The tool continues to mill the hole according to the preset feed rate until the hole is processed.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

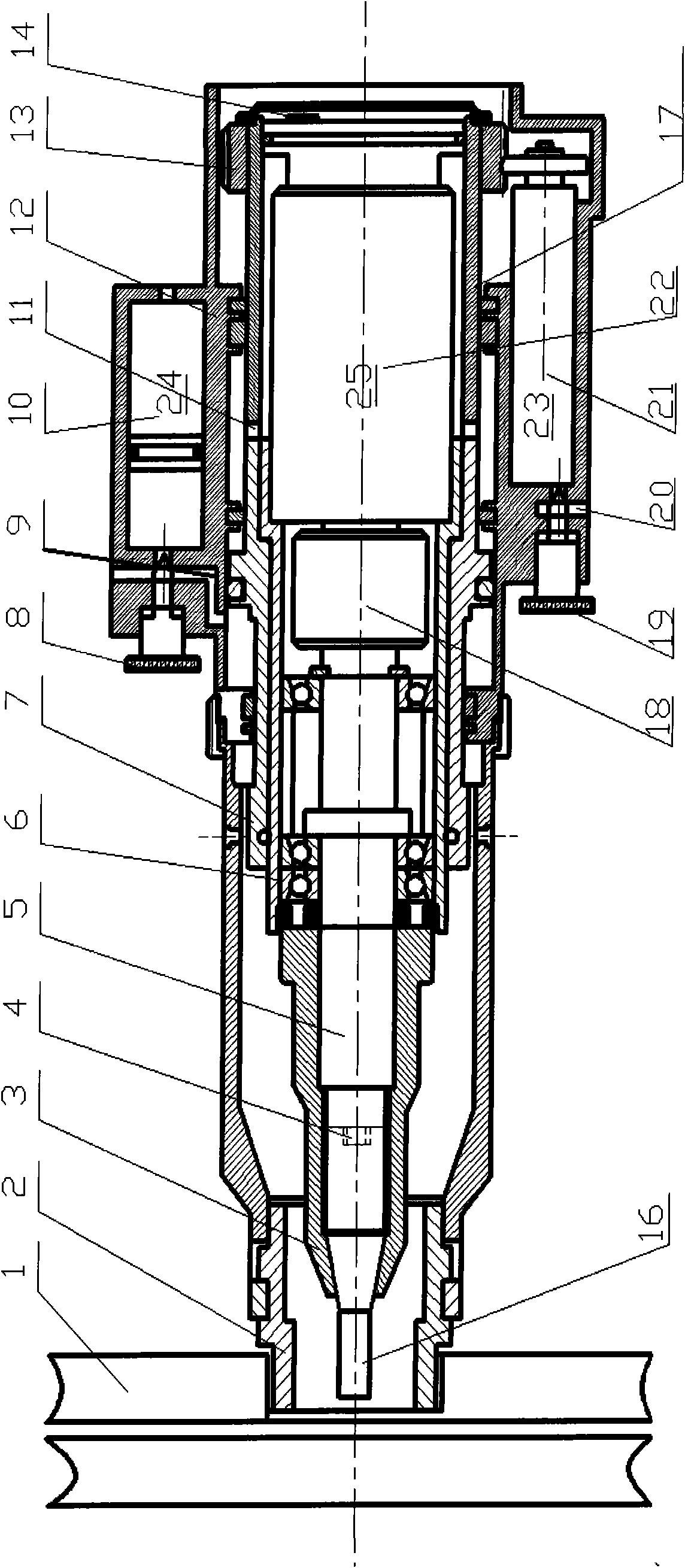

The invention discloses a method for helically milling a hole and a device thereof. The method comprises the following steps: a cutting tool automatically rotates around the center line of the cutting tool and rotates around the center of a machining hole; when the size of the hole which is to be machined changes, a distance that the center line of the cutting toll departures from the center line of a stander is adjusted and the hole is continuously to be machined; and the cutting tool is used for continuously milling the hole according to predetermined feed rate until that the hole is machined. By adopting the method and the device, the cutting tool with diameter from 6mm to 8mm is used for machining the holes with different specifications, therefore, tool changing time is reduced, finish machining is avoided, and efficiency is greatly improved. The device also can have holes with high quality on the new materials such as carbonized fiber, titanium alloy, etc. Simultaneously, the device is portable, under the condition with the same precision, greatly reduces dependence to machine tools with large scale and high precision, can combine with manipulators, and can complete the work for milling holes with high precision in the whole assembly of an airplane whole components assembly.

Description

technical field [0001] The invention relates to a helical milling method and a device thereof, in particular to a helical milling method and a device for machining high-precision holes with different diameters in aviation manufacturing equipment design, manufacturing technology and high-strength composite material manufacturing. Background technique [0002] Now our country is in a period of rapid development of manufacturing technology. As the main basic technology of manufacturing technology, cutting processing has made great progress with the development of manufacturing technology. It has entered the stage of developing high-speed cutting, developing new cutting technology and processing methods, A new stage of development characterized by the provision of a complete set of technologies. Aerospace is one of the most important components of the manufacturing industry and the industry with the most high-tech enrichment. In aviation manufacturing, a large number of parts n...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23C3/00B23Q5/04B23Q1/26B23Q5/32

Inventor 秦旭达陈仕茂刘伟成滑松冀晓来

Owner TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com