Preparation method of an in situ pore-forming self-setting calcium phosphate composite tissue engineering scaffold

A composite tissue, calcium phosphate technology, applied in the field of biomedical engineering, can solve the problems of decreased scaffold strength, low strength of calcium phosphate materials, poor mechanical properties, etc., and achieve good strength, good mechanical properties and cell affinity, strength. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Dissolve gelatin in deionized water, stir with a thermostatic magnetic stirrer at 60°C for 2 hours to obtain a gelatin aqueous solution with a gelatin mass percentage of 30%. Leave the prepared solution to stand for 1 hour, filter to remove insolubles, and put it in a container In standby.

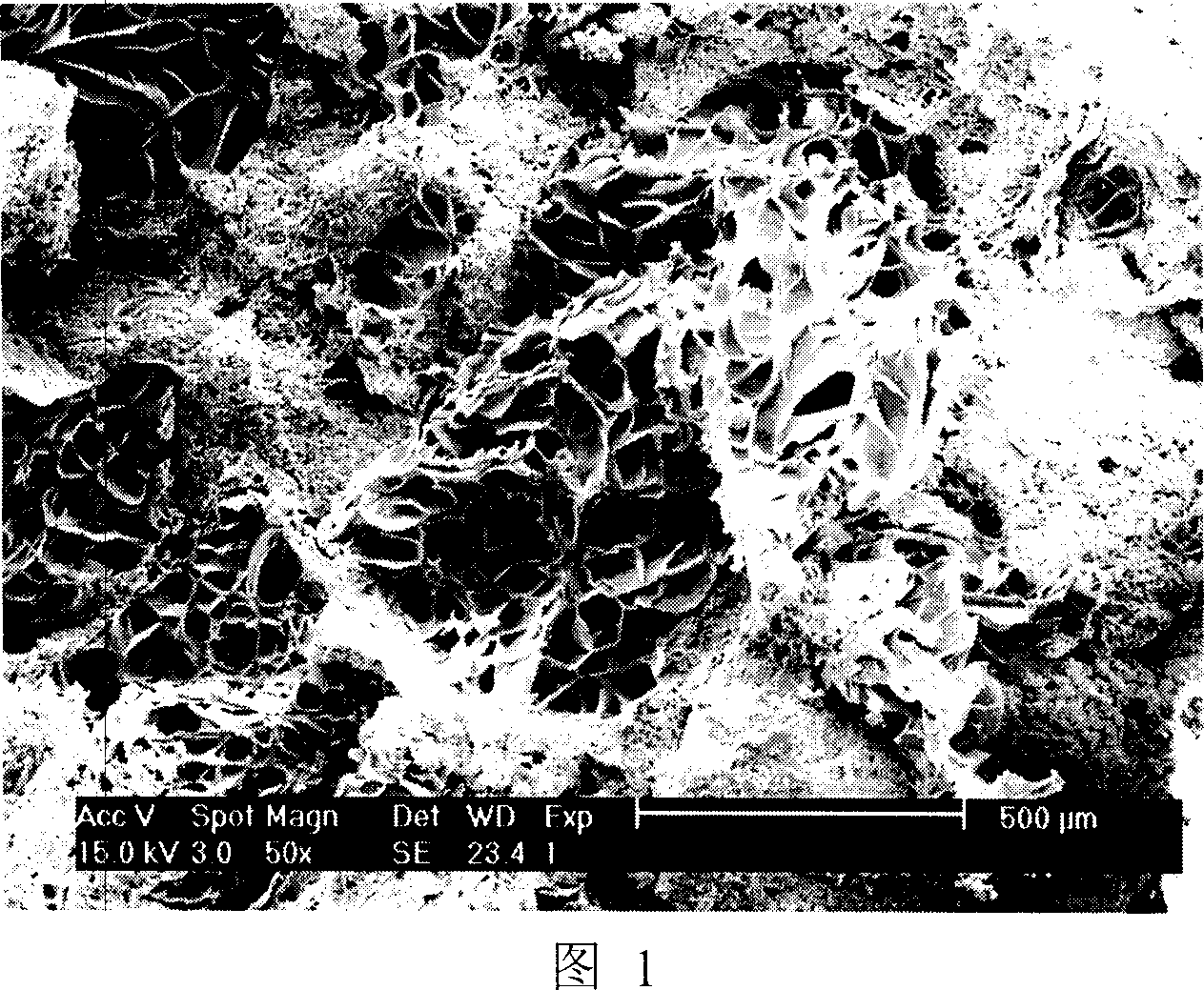

[0028] 2. Select α-tricalcium phosphate (α-TCP) + calcium hydrogen phosphate dihydrate (DCPD) + calcium carbonate (CaCO) with a total porosity of about 70% and a pore size of 100~400μm. 3 ) + Hydroxyapatite (HA) + Magnesium phosphate (Mg 3 (PO 4 ) 2 )+Sodium hydrogen phosphite (NaHSO 3 ) System bone cement porous scaffold material, put the porous scaffold into a microwave drying oven, dry at 37°C for 0.5 hours, take it out, immerse it in the gelatin aqueous solution, put it in a vacuum dryer, vacuum for 4 hours, make the gelatin aqueous solution under pressure and It is poured into the pores of the porous stent under the action of capillary force.

[0029] 3. Take out the stent mater...

Embodiment 2

[0031] 1. Prepare 0.05% chitosan solution and 4% gelatin solution with 1% acetic acid, stand for 48 hours, filter separately, and then mix the two solutions according to the volume ratio of 1:1 , And obtain chitosan / gelatin solutions with chitosan and gelatin mass percentages of 0.025% and 2%, respectively, for use.

[0032] 2. Use β-tricalcium phosphate (β-TCP) + calcium hydrogen phosphate dihydrate (DCPD) system bone cement porous scaffold material with a total porosity of about 40% and a pore size of 50-300μm, and put the porous scaffold into ordinary electric heating In a drying box, dry for 60 hours at 30°C, take it out, immerse it in the chitosan / gelatin aqueous solution prepared in step 1, put it in a vacuum dryer, vacuum for 0.5 hours, make the chitosan / gelatin aqueous solution under pressure and capillary force Under the action, it is poured into the pores of the porous scaffold.

[0033] 3. Take out the scaffold material filled with chitosan / gelatin blend in the pores, d...

Embodiment 3

[0035] 1. Prepare a silk fibroin solution with a mass percentage concentration of 1% and a sodium alginate solution with a mass percentage concentration of 6% with distilled water, stand for 24 hours, filter separately, and then mix the two solutions in a volume ratio of 1:1. Glutaraldehyde, which accounts for 1% of the total protein content of the solution, is added as a cross-linking agent to obtain a silk fibroin / sodium alginate mixed solution with a mass content of 0.5% and 3% of silk fibroin and sodium alginate, respectively, for use.

[0036] 2. Use tetracalcium phosphate (TTCP) + anhydrous calcium hydrogen phosphate (DCPA) + calcium carbonate (CaCO) with a total porosity of about 90% and a pore size of 50~400μm 3 ) System bone cement porous scaffold material, put the porous scaffold into a drying box, dry at 60°C for 30 hours, take it out, immerse it in the silk fibroin / sodium alginate aqueous solution prepared in step 1, put it in a vacuum bottle, and vacuum for 4 hours , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com